High-tower compound fertilizer slurry emulsifier

A compound fertilizer and emulsifier technology, which is applied in the field of high-tower compound fertilizer slurry emulsifiers, can solve problems such as incomplete emulsification and large particle material precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

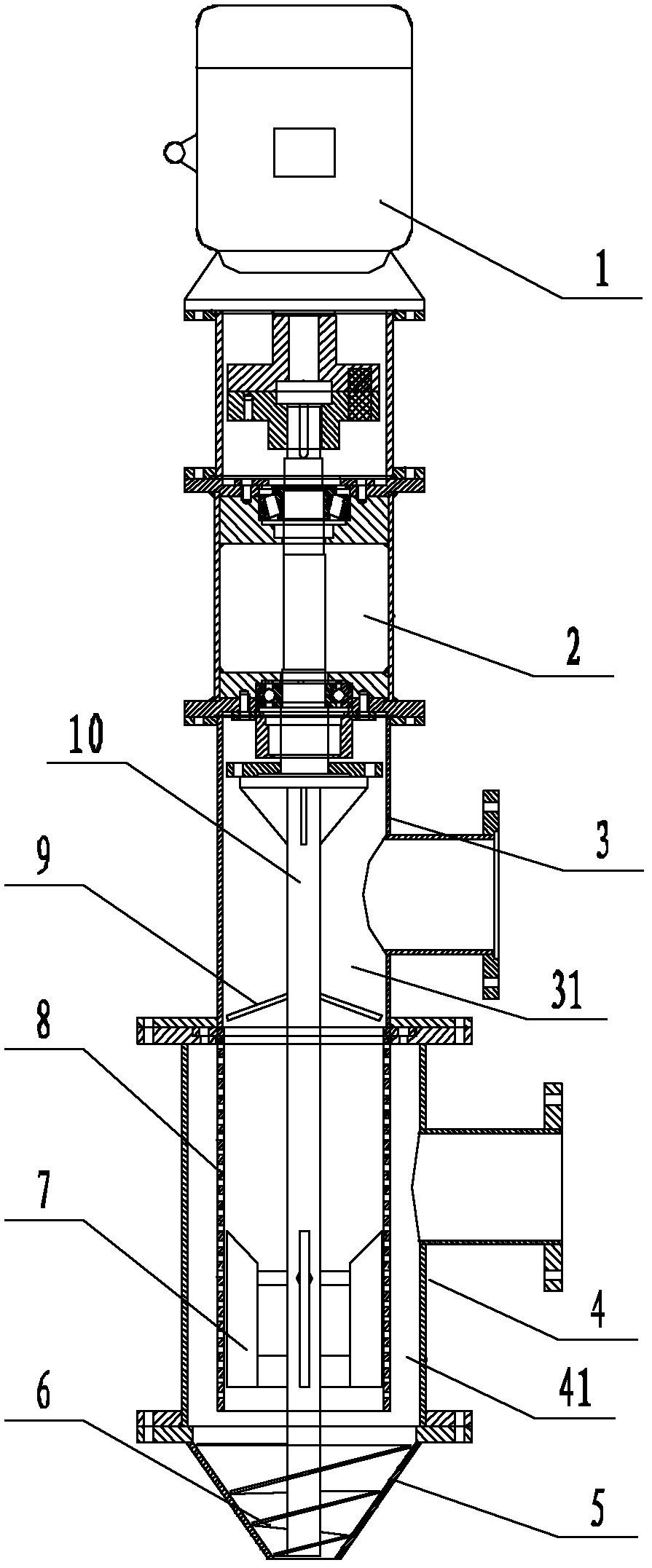

[0033] Examples of the present invention are figure 1 As shown, includes a mixer, the mixer includes a first cylinder 3 and a second cylinder 4, the first cylinder 3 and the second cylinder 4 are connected up and down.

[0034] The cylinder wall of the first cylinder 3 is provided with a feed inlet, and the inside is provided with a first mixing chamber 31, the feed inlet communicates with the first mixing chamber 31, and the cylinder wall of the second cylinder 4 is provided with a first mixing chamber 31. A discharge port, the bottom is provided with a second discharge port, the inside is provided with a second mixing chamber 41, the first discharge port and the second discharge port are all connected with the second mixing chamber 41, and the first mixing chamber The material chamber 31 communicates with the second material mixing chamber 41 .

[0035] The first cylindrical body 3 and the second cylindrical body 4 are pierced with a rotating shaft 10, the rotating shaft 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com