Seal for an adjustment device for a supercharging device

一种调节装置、增压装置的技术,应用在燃气轮机装置、发动机元件、机器/发动机等方向,能够解决轴和调节装置故障概率升高、密封件安装繁琐、增加时间和成本等问题,达到改善密封效果、快速安装或布置、防止涡轮逸出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

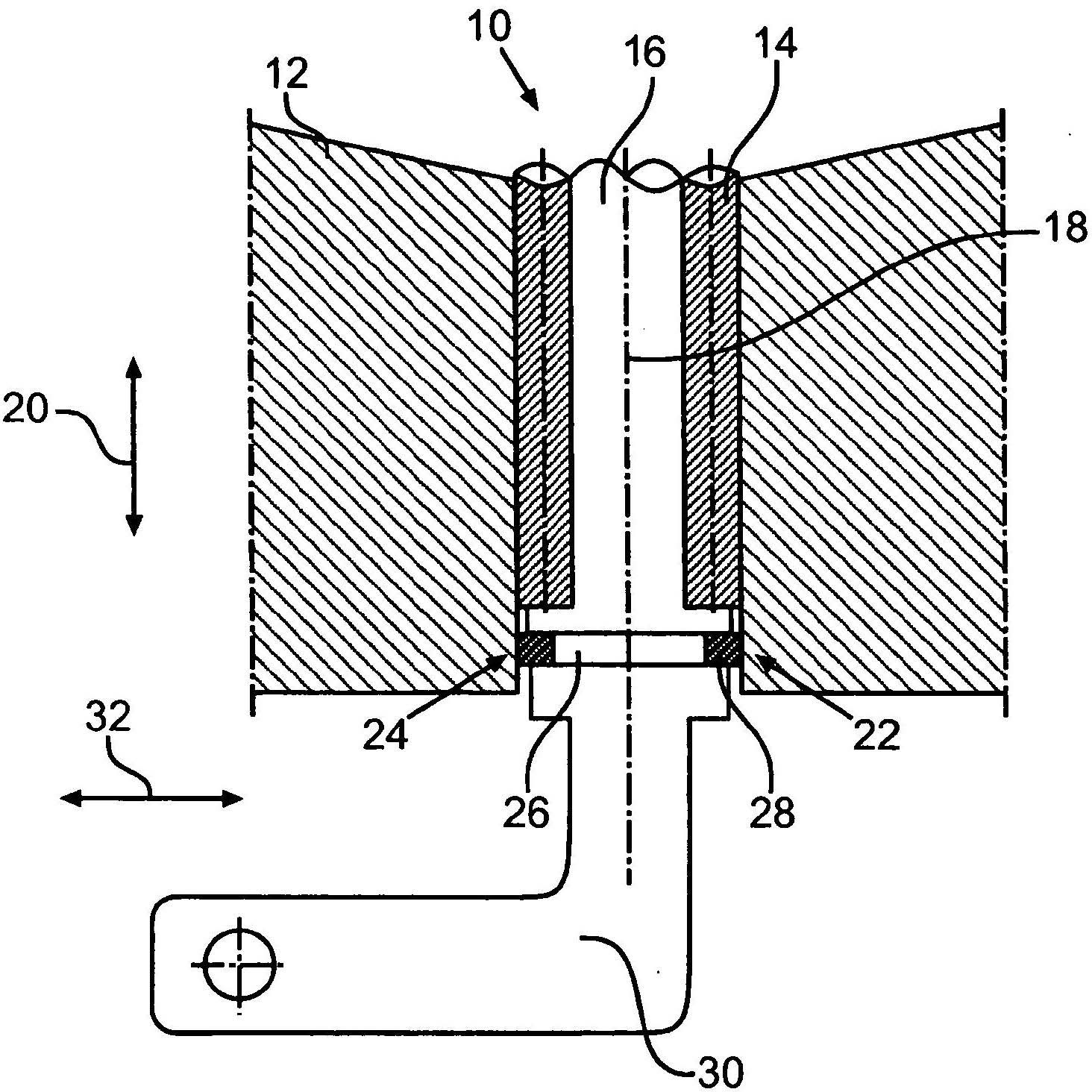

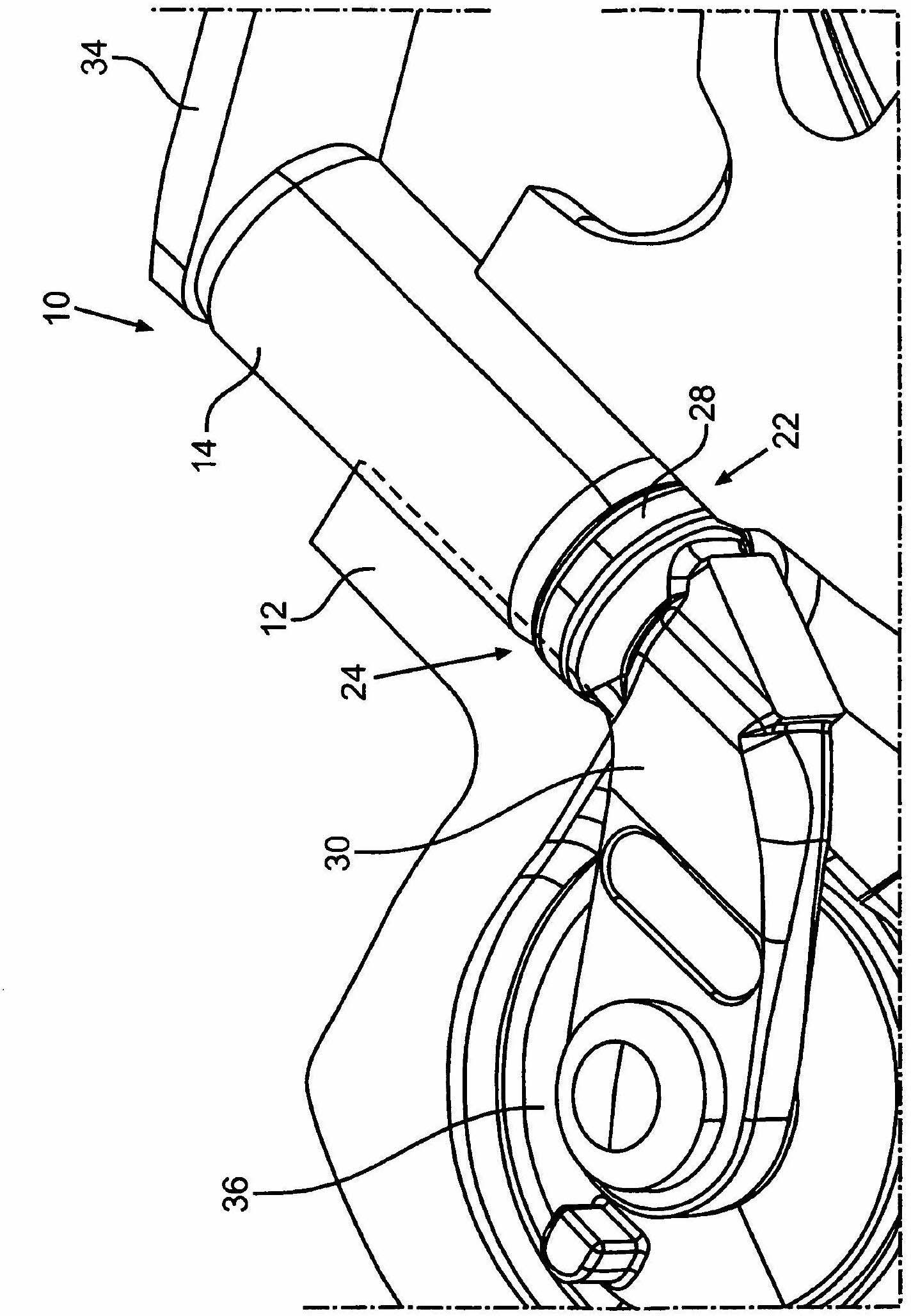

[0024] figure 1 Shown is a regulating device 10 for a charging device in the form of an exhaust-gas turbocharger with a housing 12, wherein the housing 12 is designed as a turbine housing for accommodating the exhaust-gas turbocharger. Turbo turbine wheel.

[0025] The adjusting device 10 comprises a bearing element in the form of a bushing 14 in which an adjusting shaft 16 of the adjusting device 10 is accommodated. as available from figure 1 It can be seen that the adjusting shaft 16 is mounted in the housing 12 so as to be rotatable about an axis of rotation 18 by means of a bushing 14 .

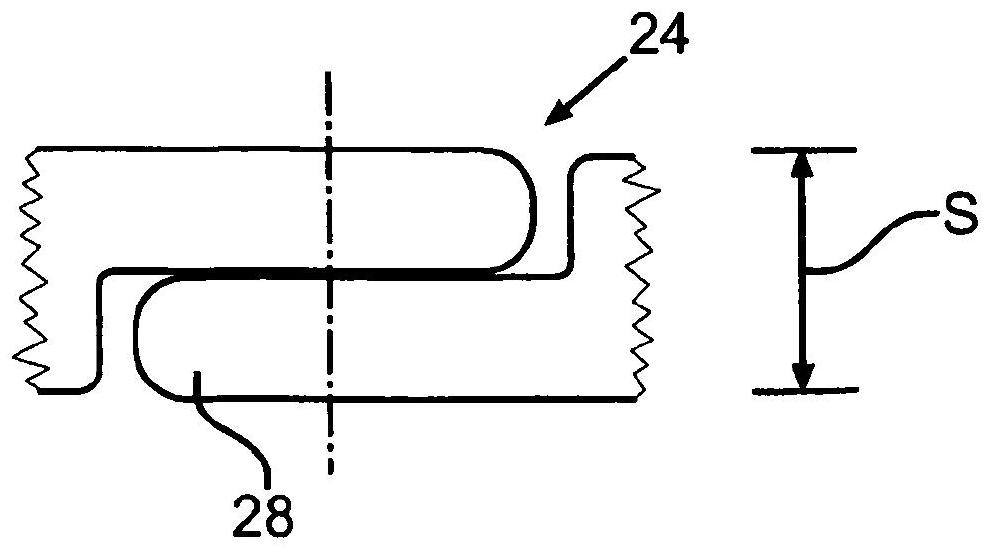

[0026] The adjusting shaft 16 has a section 22 protruding beyond the bushing 14 in the axial direction of the adjusting shaft 16 indicated by the direction arrow 20 , in which section a collar 24 of the adjusting shaft 16 is arranged.

[0027] The collar 24 also has a groove 26 in which a corresponding sealing element in the form of a sealing ring 28 is arranged, so that the sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com