Air pump structure device that can reduce or eliminate air leakage during operation

A technology of air pump and structural form, applied in pump components, variable capacity pump components, liquid variable capacity machinery, etc., can solve the problem of gas leakage at the shaft seal, and achieve the effect of reducing the loss of savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

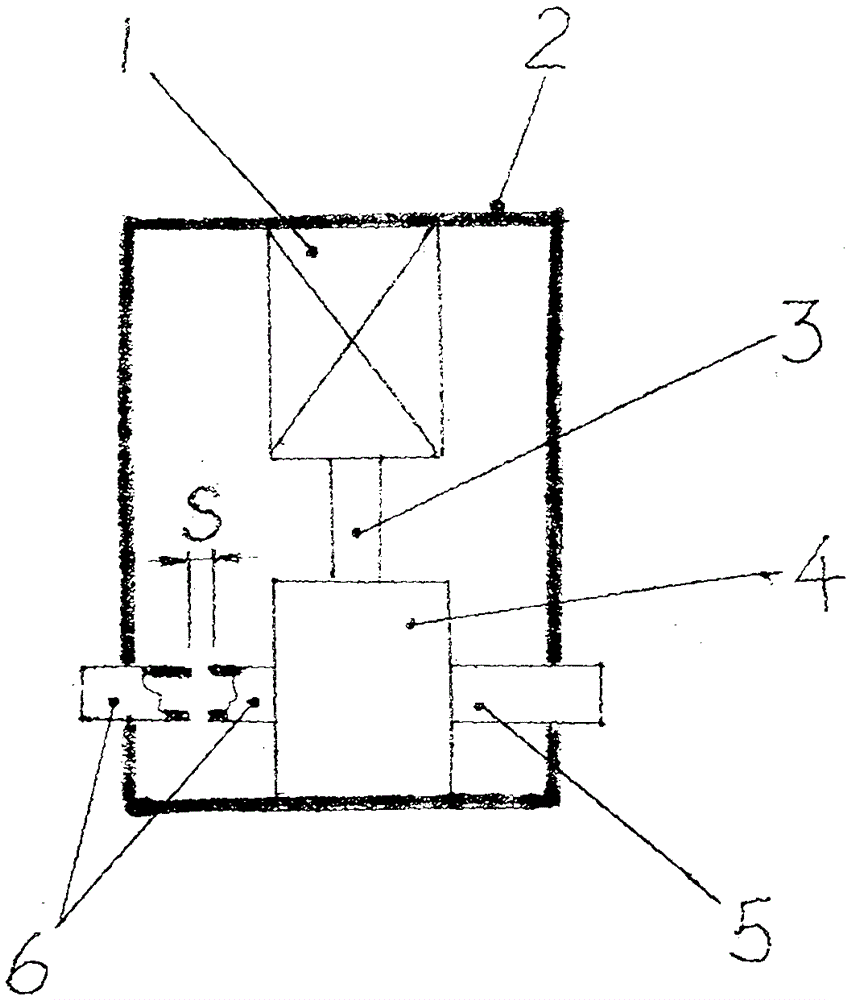

[0017] The structure of the present invention is not very complicated, and its manufacturing difficulty is not high, and its key lies in: on the basis of the structure of the conventional and common existing air pump 4, a metal sealed casing 2 surrounding the former in a three-dimensional form and supporting technologies are added Measures, can realize the leakage of gas during the operation of the present invention to different degrees, and even finally realize the possibility of preventing gas molecules from leaking from the present invention.

[0018] The main body of the structure of the first embodiment of the present invention is shown in the accompanying drawings:

[0019] The air pump 4 and the metal sealed casing 2 that surrounds the air pump 4 in a three-dimensional form are used as an integral structure, and the air intake pipe 6 has a cut-off part of the slit width S in the inner cavity of the casing 2 . .

[0020] A truncated slit width S is set in the straight l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com