Electroosmosis belt type squeezing sludge dehydration equipment

A technology of sludge dehydration and electroosmosis, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of poor sludge dehydration effect, improve the efficiency of press dehydration, easy replacement, and reduce waste gas pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

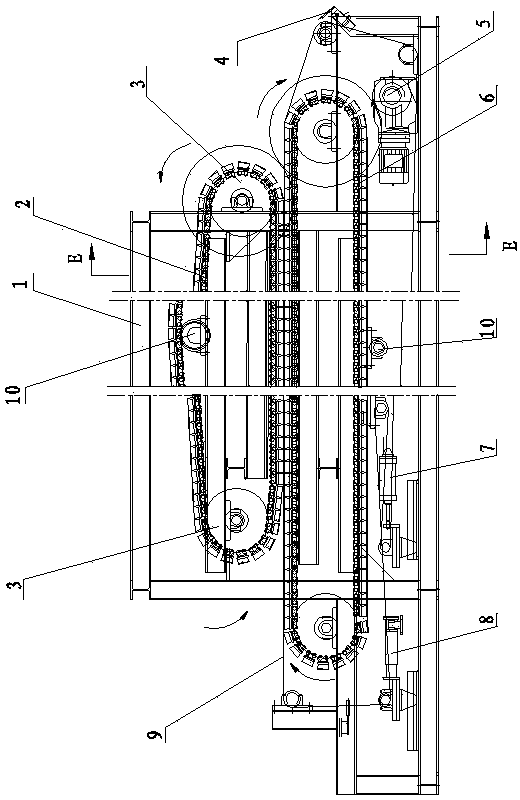

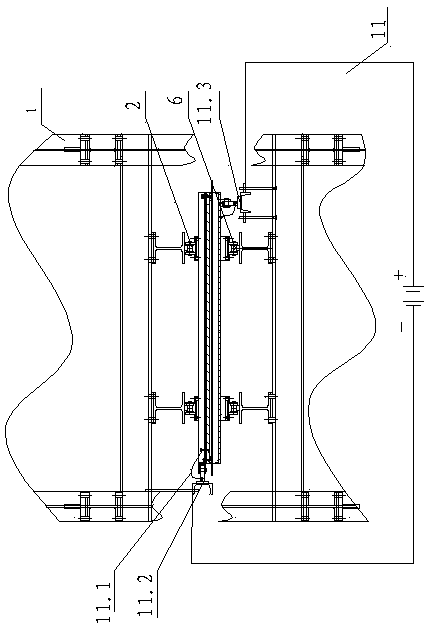

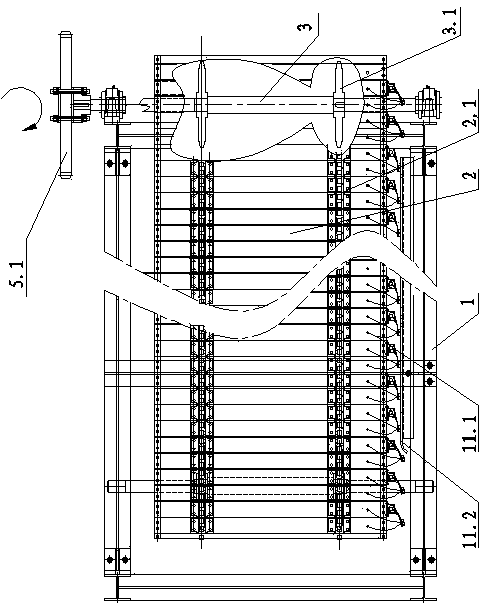

[0026] [0025] figure 1 and figure 2 The shown embodiment is an electroosmotic belt press sludge dewatering equipment with a daily output of 10 tons of sludge cake with a dryness of 50%, which includes a frame 1, an upper press belt 2, a transmission shaft 3, a scraper 4, a power machine 5, Lower press belt 6, tensioning device 7, deviation correcting device 8, filter belt 9, support roller 10 and power supply 11. Frame 1 is basic structure among the present invention, and it is the horizontal position elongated steel structure truss that it welds with I-beam, is provided with the wedge-shaped flat groove that width is 1600mm along the length direction at the waist. The wedge-shaped flat groove is a tapered structure, and the height of the inlet end is 12mm larger than the height of the outlet end. When the wedge-shaped flat groove of this size passes through the upper press belt 2, the lower press belt 6 and the filter belt 9, the wet sludge of 30mm is flatly spread, and t...

Embodiment 2

[0028]This embodiment is an electroosmosis belt press sludge dewatering equipment with a daily output of 40 tons of sludge cake with a dryness of 50%. Its main structural parameters are: the width of the wedge-shaped flat groove of frame 1 is 2800mm, and the height of the inlet end is 18mm larger than that of the outlet end. The width of the upper press belt 2 and the lower press belt 6 is 2300mm. Because the width is larger, in order to increase the strength, the upper press belt 2 and the lower press belt 6 are all manufactured with 5 chains in the present embodiment. The width of the filter belt is 2500mm, and the voltage of the power supply 11 used is 100V. In a wedge-shaped flat groove of this size, the upper press belt 2 and the lower press belt 6 can produce a pressing force of 1.7kgf / cm on the wet sludge spread on the filter belt 9 for 30 mm 2 ~1.9kgf / cm 2 . The wet sludge squeezed in this example is urban domestic sewage sediment, and the degree of acid reduction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com