Pulsed laser welding method for high-pressure sealed valve body component

A pulse laser and high-pressure sealing technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high output heat affecting welding deformation, difficulty in effective control of welding quality, and inability to meet the use requirements, etc., to achieve Mass production with stable quality, small deformation and moderate depth of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

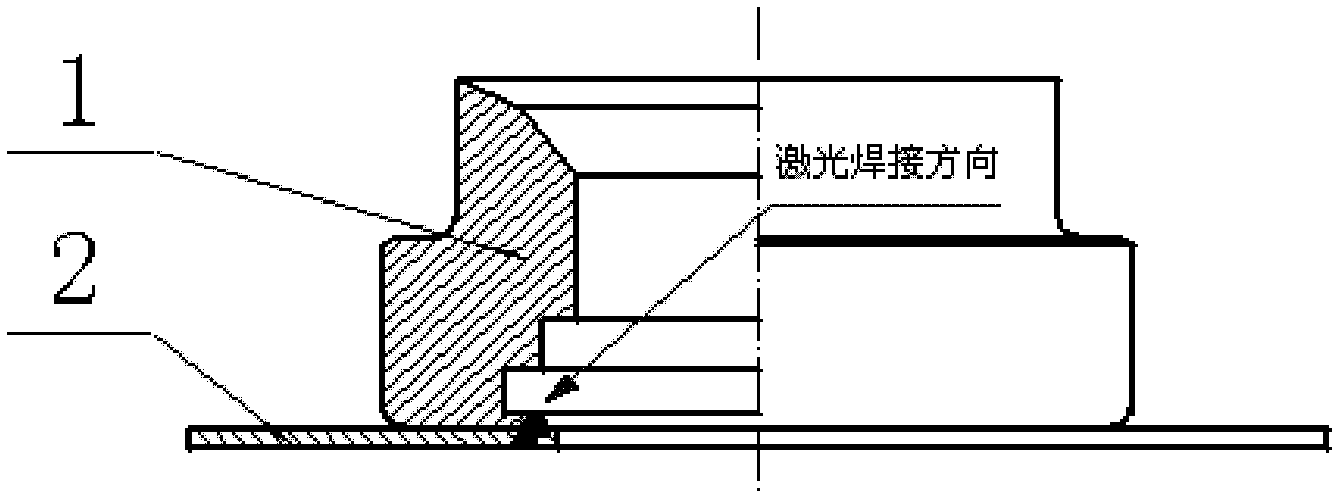

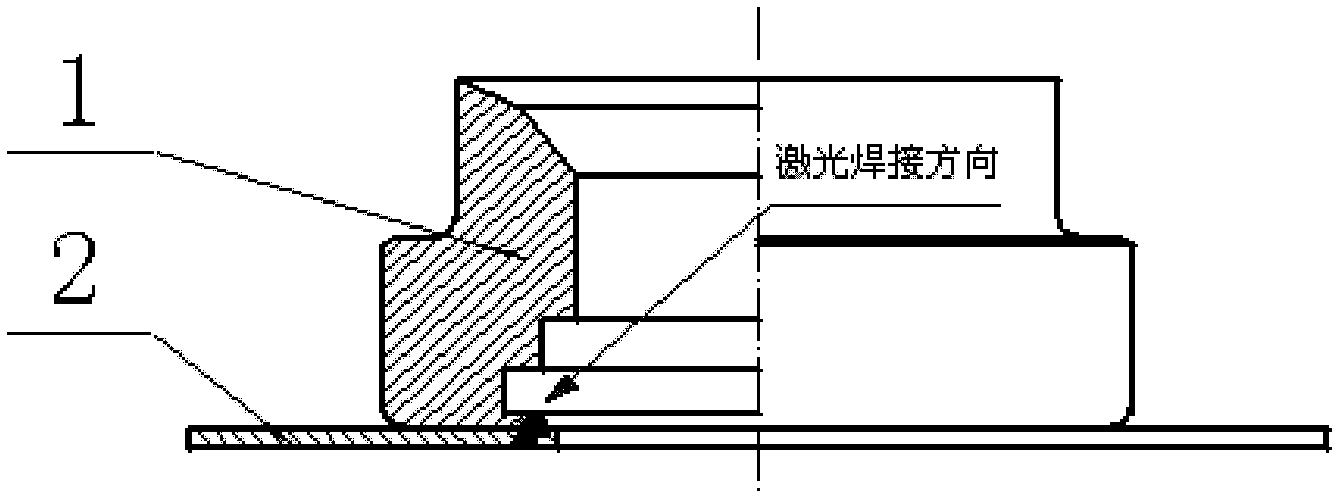

[0015] see figure 1 . The present invention will be further illustrated in the following examples, which are only used to illustrate the present invention and not to limit the present invention.

[0016] Preparation before welding. Use mechanical methods to remove the oxides on the surface of the joints of the parts, and use the organic cleaning agent acetone to clean the joints near the joints to be welded strictly before welding. The rigid fixing method is used to fit the valve seat and the gasket tightly into the fixture, "eight-point symmetry, bolt fastening", and the pre-tightening force is adjusted by the thread. The shrinkage of the shaft and diameter after welding is controlled by "side top pressure" to reduce angular deformation and bending deformation, thereby controlling the coaxiality of the valve seat and gasket, and ensuring the sealing effect of the valve body assembly to the greatest extent.

[0017] According to the welding characteristics of stainless stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com