Method and device for ultrasonic testing

An ultrasonic and pulse detection technology, used in measuring devices, solids analysis using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, etc., which can solve problems such as long detection time and inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

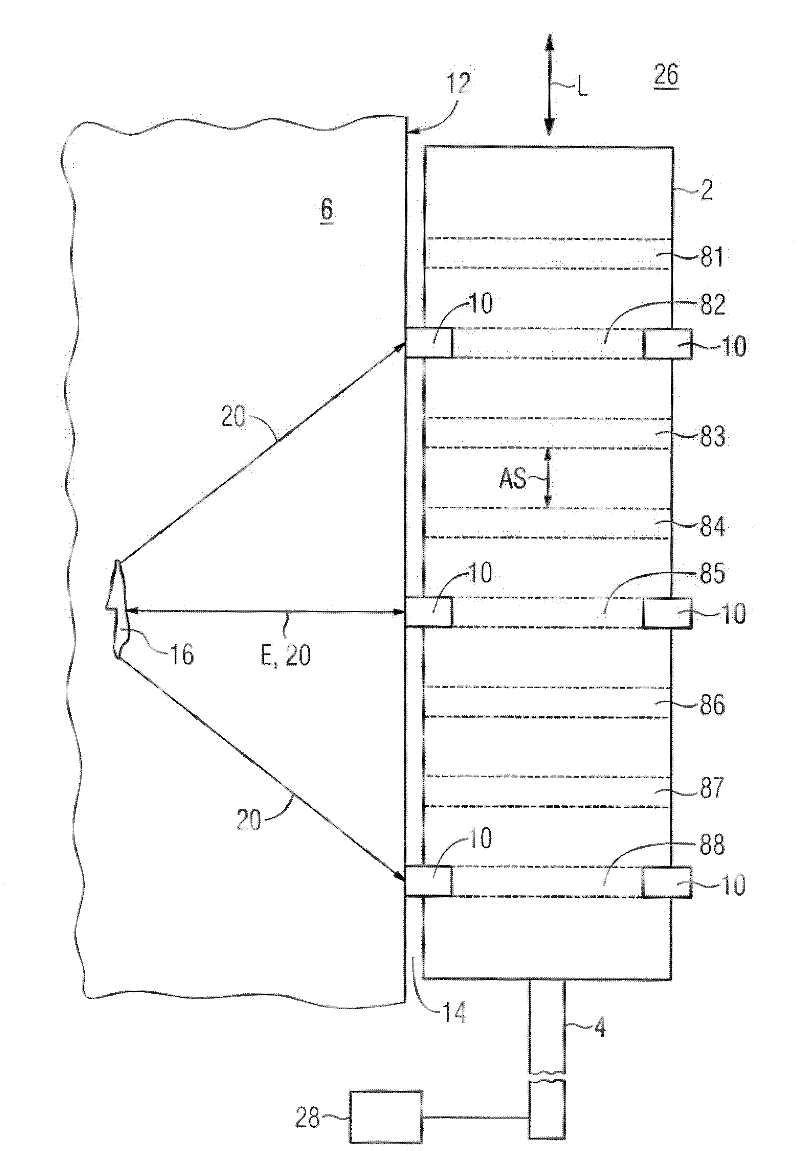

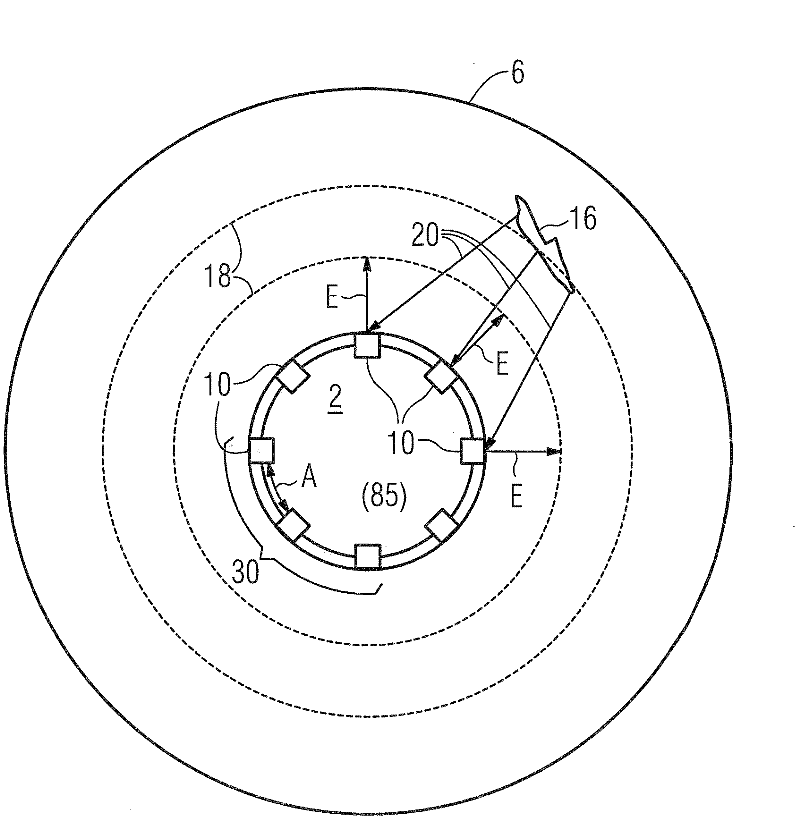

[0047] figure 1 The probe 2 in the bore 26 is shown in longitudinal section. The probe 2 is inserted into the hole 26 by means of the rod 4 of the test gun. Alternatively, the probe 2 is inserted into the hole 26 by means of a push / pull device using a flexible shaft. The test object should be, for example, a hollow shaft 6 with an axial center hole 26 . The probe 2 has eight sensor rings 81 to 88 arranged one behind the other in the axial direction L. In the illustrated embodiment, the axial direction L of the hole coincides with the central longitudinal axis of the probe 2 . Each sensor ring 81 to 88 has eight ultrasonic transducers 10 that function both as ultrasonic transmitters and ultrasonic receivers. The position of the ultrasonic transducer 10 in the circumferential direction of the sensor rings 81 to 88 changes from one sensor ring 81 to 88 to the next sensor ring. This results in figure 1 Only the ultrasonic transducers 10 of the sensor rings 82 , 85 and 88 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com