Magnetic coupling

A magnetic coupler and permanent magnet technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of high pressure, distribution influence, time-consuming and labor-consuming, etc., and achieve the effect of simple structure and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

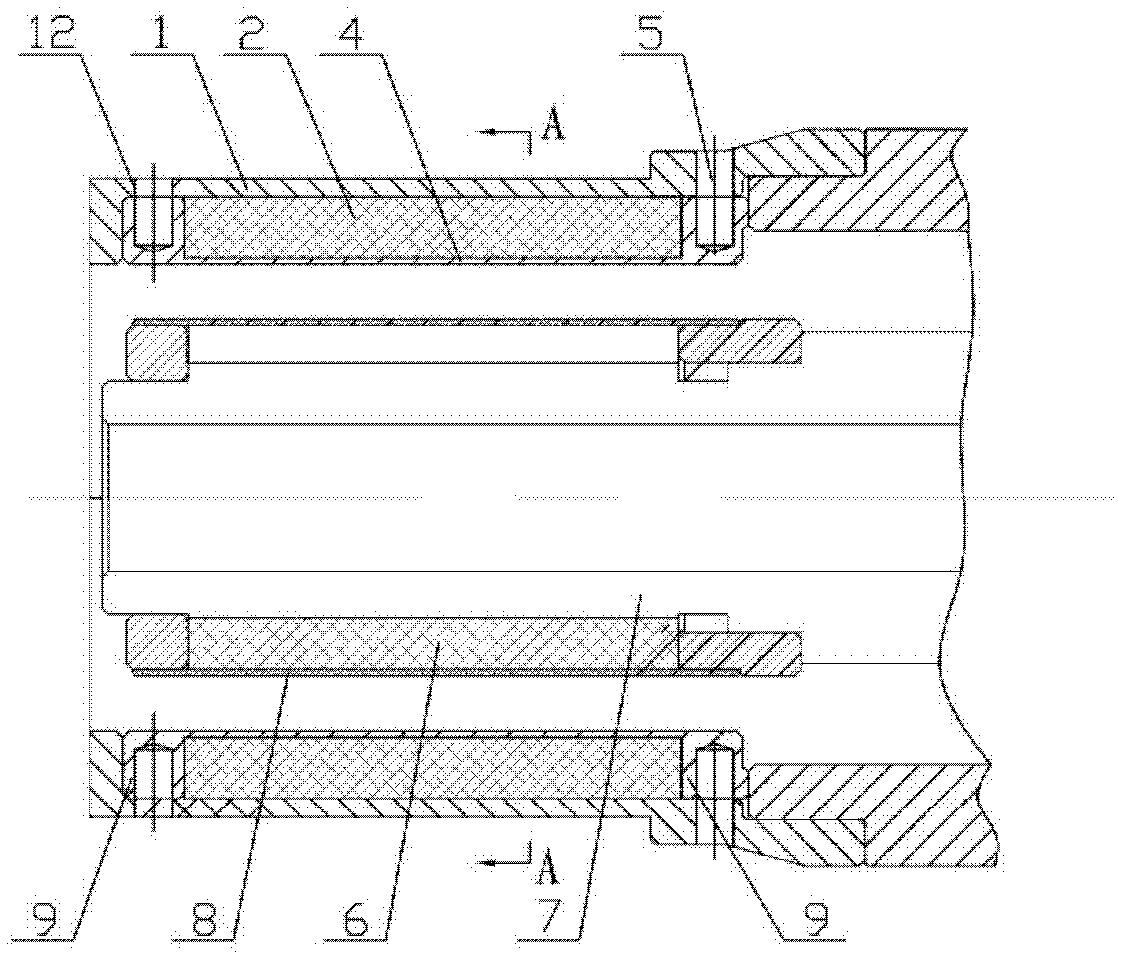

[0019] Specific implementation mode one: as Figure 1-Figure 6 As shown, a magnetic coupler, the magnetic coupler includes a housing 1, a casing 8, an inner rotor yoke 7 and several permanent magnets, and several permanent magnets include several outer permanent magnets 2 and several inner permanent magnets. magnet 6, the magnetic coupler also includes a sleeve 4, two end rings 9 and several partitions 3,

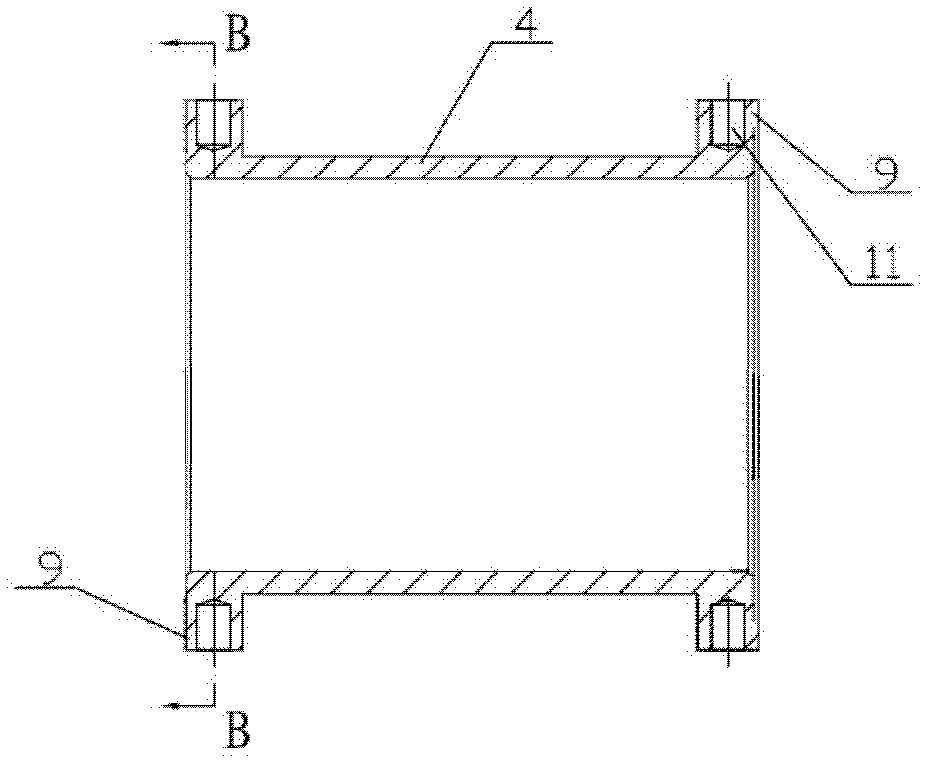

[0020] Both ends of the sleeve 4 are integrally formed with an end ring 9, the sleeve 4 is coaxially arranged with the two end rings 9, the inner diameter of the sleeve 4 is the same as that of the end ring 9, and the outer diameter of the sleeve 4 is smaller than that of the end rings 9. The outer diameter of the ring 9 and the outer circumferential surface of the end ring 9 are evenly opened with several rectangular grooves 10, and several rectangular grooves 10 are opened along the axial direction of the sleeve 4, and the several rectangular grooves 10 on the two end rin...

specific Embodiment approach 2

[0021] Specific implementation mode two: as figure 1 and image 3 As shown, in the magnetic coupler described in Embodiment 1, several threaded holes or several light holes 11 are evenly provided on the outer circumferential surface of the end ring 9, and several threaded holes 11 on the housing 1 are provided with the end ring 9. Or several connecting holes 12 corresponding to several light holes 11, the end ring 9 is connected to the housing 1 through several screws or several pins 5, which is convenient for assembly and disassembly.

specific Embodiment approach 3

[0022] Specific implementation mode three: as figure 2 As shown, in the magnetic coupling described in Embodiment 1, the outer edge of the radial cross-section of the inner rotor yoke 7 is a regular 2P polygon (2P planes are formed on the outer surface of the inner rotor yoke 7), and P is a permanent magnet pole pair number.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com