Method for fabricating graphene electrode materials through pulsed laser deposition and application thereof

A pulsed laser deposition and graphene electrode technology, applied in the field of electrochemical energy storage, can solve problems such as instability, discontinuity, and obstacles to large-scale utilization of renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

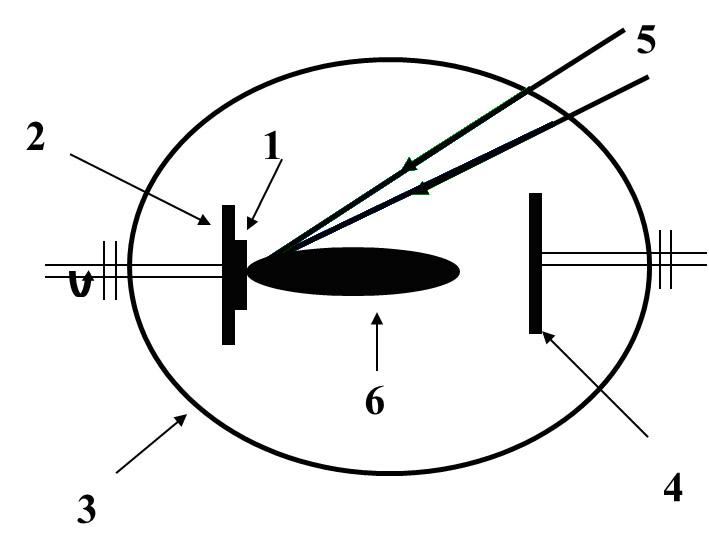

Image

Examples

Embodiment 1

[0023] (1) Graphene oxide was prepared by the Hummers method. The specific process is briefly described as follows: 5 g of graphite was placed in 120 ml of concentrated sulfuric acid, 2.5 g of sodium nitrate was added, and 15 g of KMnO was slowly added in an ice-water bath. 4 , kept stirring for 30 min, and then slowly added 200 ml of deionized water. Stirring was continued for 15 min. Add about 200 ml of deionized water at 60°C and 30% H 2 o 2 The solution was about 30 ml, the mixture changed from tan to bright yellow, filtered while hot, washed and dried in a vacuum oven at 60°C to obtain graphite oxide. Then graphite oxide was calcined in air atmosphere at 300°C for 10 min to obtain graphene oxide. (Introduce the method in words), after careful grinding, press it into tablets at 10MPa on the tablet machine as the target material;

[0024] (2) Place the pretreated nickel foam and graphene oxide targets in a vacuum chamber, adjust the distance between the target and the s...

Embodiment 2

[0028] (1) Graphene oxide was prepared by the Hummers method (see Example 1 (1) for the specific process), and after careful grinding, it was pressed into tablets at 10 MPa on a tablet machine as a target material;

[0029] (2) Place the pretreated nickel foam and graphene oxide targets in a vacuum chamber, and adjust the distance between the target and the substrate to be 1 cm. Evacuate the vacuum chamber to 10 with mechanical pump and molecular pump -4 Pa;

[0030] (3) Use Nd:YAG pulsed laser to focus the laser beam (wavelength: 1064nm, repetition frequency: 10Hz) onto the cobalt target through the lens and optical window, the high energy of the laser beam melts and evaporates the target plume in an instant, And deposited on the nickel foam substrate, the deposition time is 60min, that is, the graphene electrode material is prepared.

[0031] (4) Turn off the molecular pump, mechanical pump and laser, open the vacuum chamber, take out the substrate, perform characterizatio...

Embodiment 3

[0033] (1) Graphene oxide was prepared by the Hummers method (see Example 1 (1) for the specific process), and after careful grinding, it was pressed into tablets at 10 MPa on a tablet machine as a target material;

[0034] (2) Place the pretreated nickel foam and graphene oxide targets in a vacuum chamber, and adjust the distance between the target and the substrate to be 5 cm. Evacuate the vacuum chamber to 10 with mechanical pump and molecular pump -4 Pa;

[0035] (3) Use Nd:YAG pulsed laser to focus the laser beam (wavelength: 1064nm, repetition frequency: 10Hz) onto the cobalt target through the lens and optical window, the high energy of the laser beam melts and evaporates the target plume in an instant, And deposited on the nickel foam substrate, the deposition time is 60min, that is, the graphene electrode material is prepared.

[0036] (4) Turn off the molecular pump, mechanical pump and laser, open the vacuum chamber, take out the substrate, perform characterizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com