Developing solution spraying system and method and substrate product

A technology of spraying system and developer, applied in the direction of photosensitive material processing, etc., can solve the problems of uneven development and uneven developer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

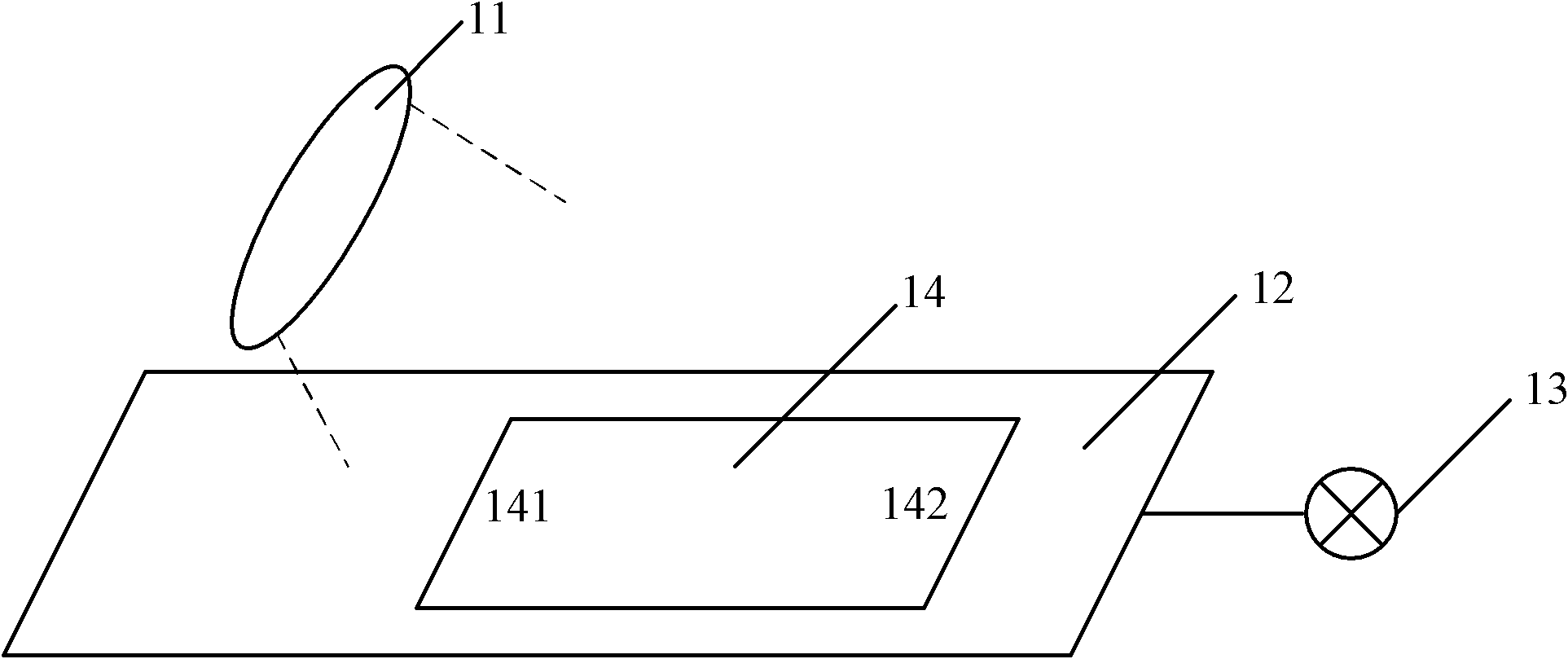

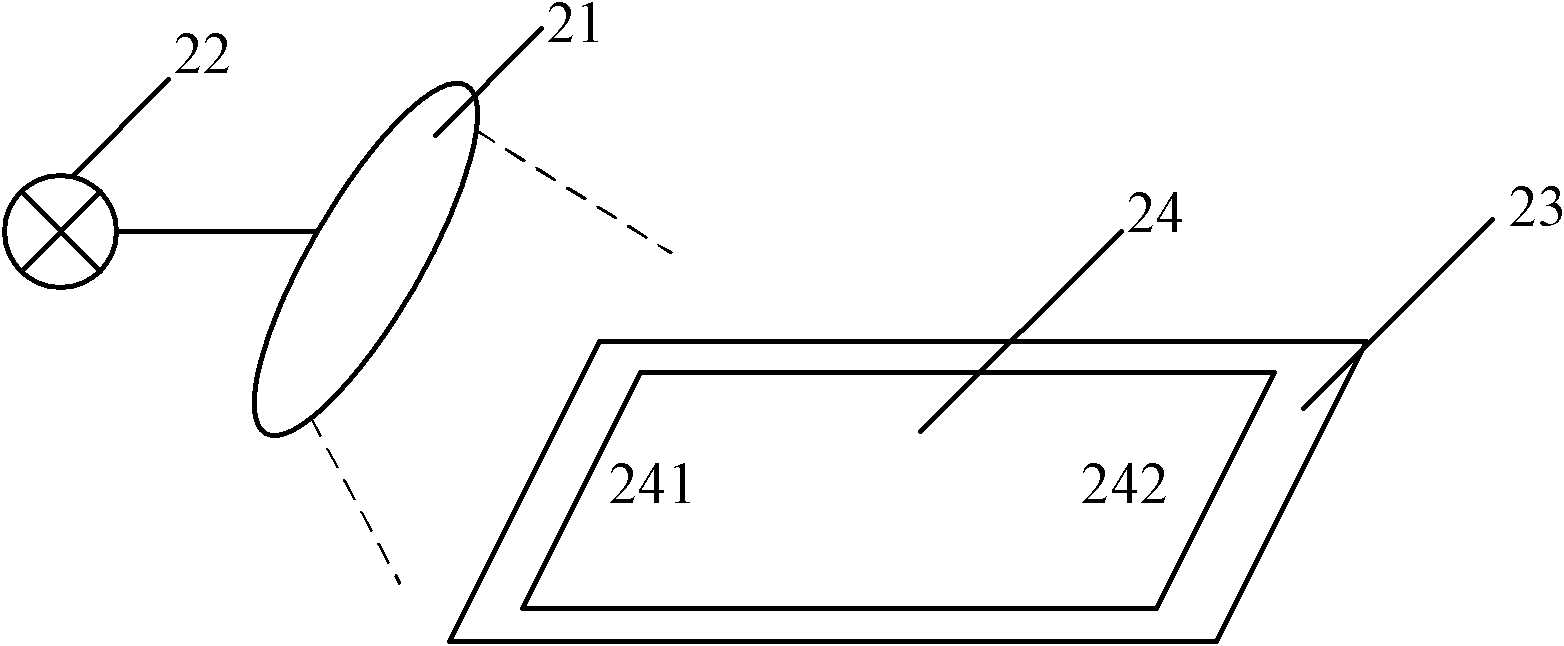

[0025] Such as figure 2 As shown, it is a schematic structural diagram of the developer spraying system proposed in Embodiment 1 of the present invention, including a spray head 21, a driving device 22, and a fixed machine platform 23 located below the spray head 21, wherein:

[0026] The fixed machine 23 is used to carry the substrate 24, for example, the substrate 24 may be a glass substrate;

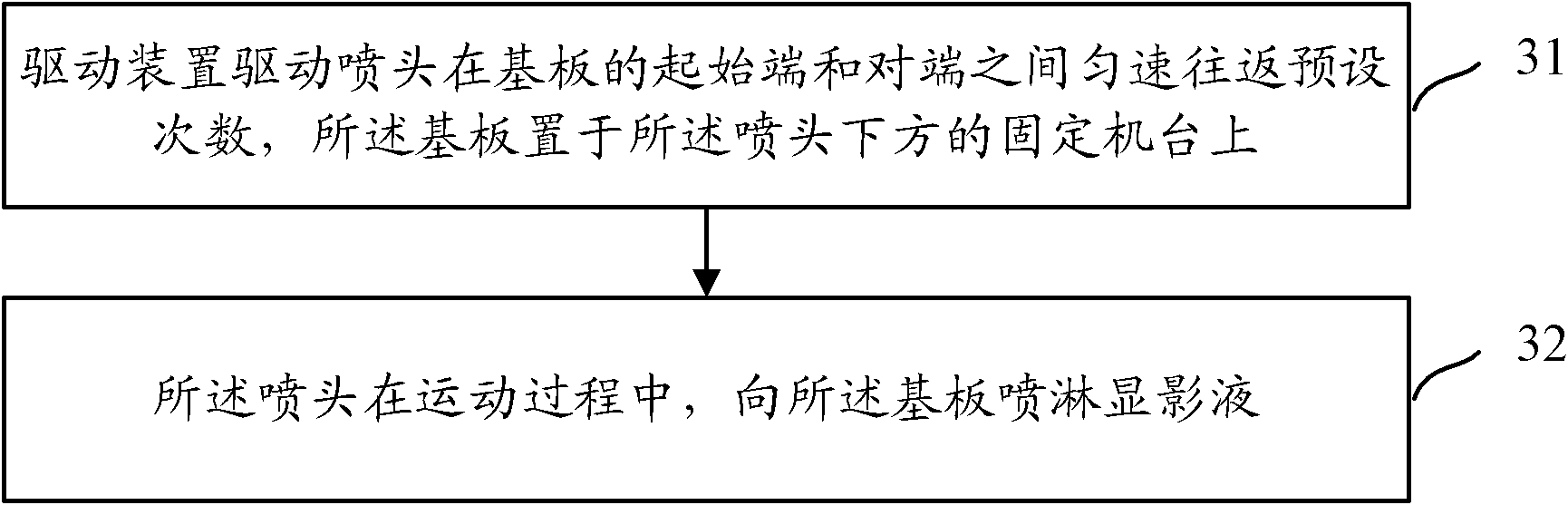

[0027] The driving device 22 is used to drive the spray head 21 to go back and forth at a constant speed for a preset number of times between the starting end 241 and the opposite end 242 of the substrate 24;

[0028] The spray head 21 is used for spraying developing solution onto the substrate 24 during the movement.

[0029] The substrate includes a starting end and an opposite end. In Embodiment 1 of the present invention, the end that first enters the spraying area of the shower head 21 is called the starting end, and the other end is called the opposite end.

[0030] Wherein...

Embodiment 2

[0048] Such as Figure 6 As shown, it is a schematic structural diagram of the developer spraying system proposed in Embodiment 2 of the present invention, including the first spray head 61 and the second spray head 62, the conveying device 63 located below the first spray head 61 and the second spray head 62, the driving device 64 and Rotary device 65, wherein:

[0049] The conveying device 63 is used to carry the substrate 66, wherein the conveying device 63 can be a conveyor belt or a set of conveying rollers;

[0050] The driving device 64 is used to drive the conveying device 63 to move at a constant speed at a preset speed, and drive the substrate 66 to pass through the spraying area of the first nozzle 61 along the direction from the starting end 661 to the opposite end 662, wherein the substrate 66 includes a starting end 661 and an opposite end 662. In Embodiment 2 of the present invention, one end that first enters the spraying area of the first shower head 61 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com