Gas wave refrigerator

A gas wave refrigerator and casing technology, which is used in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of casing leakage and the inability to adjust the size of the gas distributor nozzle, so as to improve the sealing performance and improve the refrigeration efficiency. , the effect of reducing the loss of cold energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

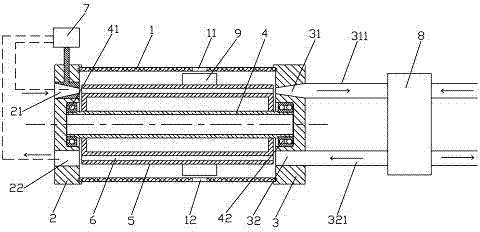

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

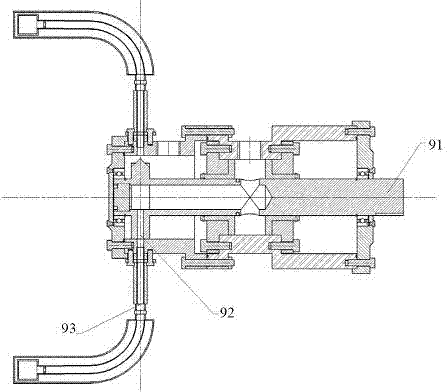

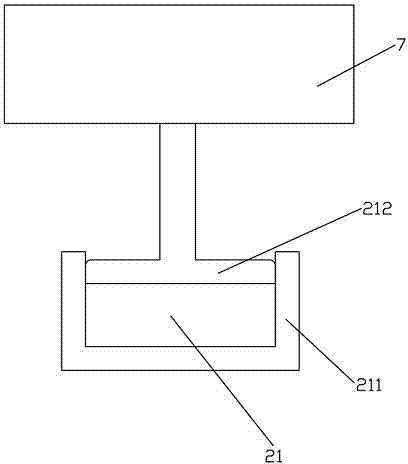

[0026] Such as figure 2 and image 3 As shown, a gas wave refrigerator provided by the embodiment of the present invention includes a casing 1 with openings at both ends, one end of the casing 1 is in sealing connection with the first end cover 2, and the other end of the casing 1 is connected with the second end cover 3 sealed connection;

[0027] The first end cover 2 and the second end cover 3 are provided with a rotating shaft 4 located in the casing, the first end cover 2 is fixed with a first bearing 41, and the second end cover 3 is fixed with a second bearing 42. The two ends of the rotating shaft 4 are respectively connected with the first bearing 41 and the second bearing 42, so as to achieve the purpose of rotationally connecting the two ends of the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com