Soap tank for on-line pickling of finished flat wire and pickling method using soap tank

A pickling and flat wire technology, which is applied in the field of saponification tank, can solve the problems of large loss of the I-shaped wheel body, high coil density, and high labor intensity of employees, and achieve high pickling and saponification efficiency, durable production cost, and low cost. Ease of use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

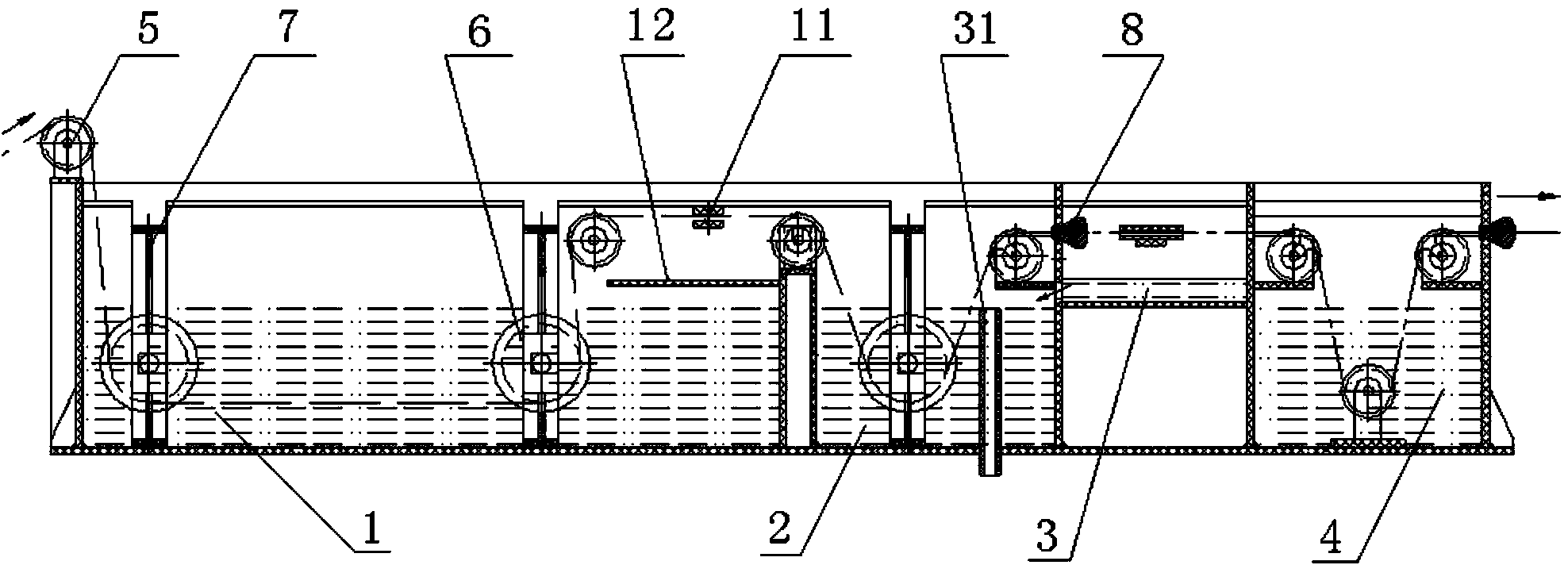

[0020] It can be seen from the structure shown in Figure 1 that this kind of saponification tank for on-line pickling of finished flat wires includes four areas of pickling area 1, clear water area 2, clear water area 2, and saponification area 4, which are distributed in sequence. 1 is the entry end of the finished flat wire. The top of the pickling area 1 is provided with a small guide wheel 5 for guiding the finished flat wire. There are also two sets of movable wheel frames 7 with large guide wheels 6 installed in the pickling area 1. There is also a clamping plate 11 at the rear of the pickling area 1 to remove the acid liquid on the finished flat wire, and a liquid baffle plate under the clamping plate 11 to prevent the small guide wheel 5 and the large guide wheel 6 from bringing the acid solution in 12. The liquid baffle 12 is installed on the vertical plate between the pickling area 1 and the clean water area 2, and a small guide wheel 5 is also installed on the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com