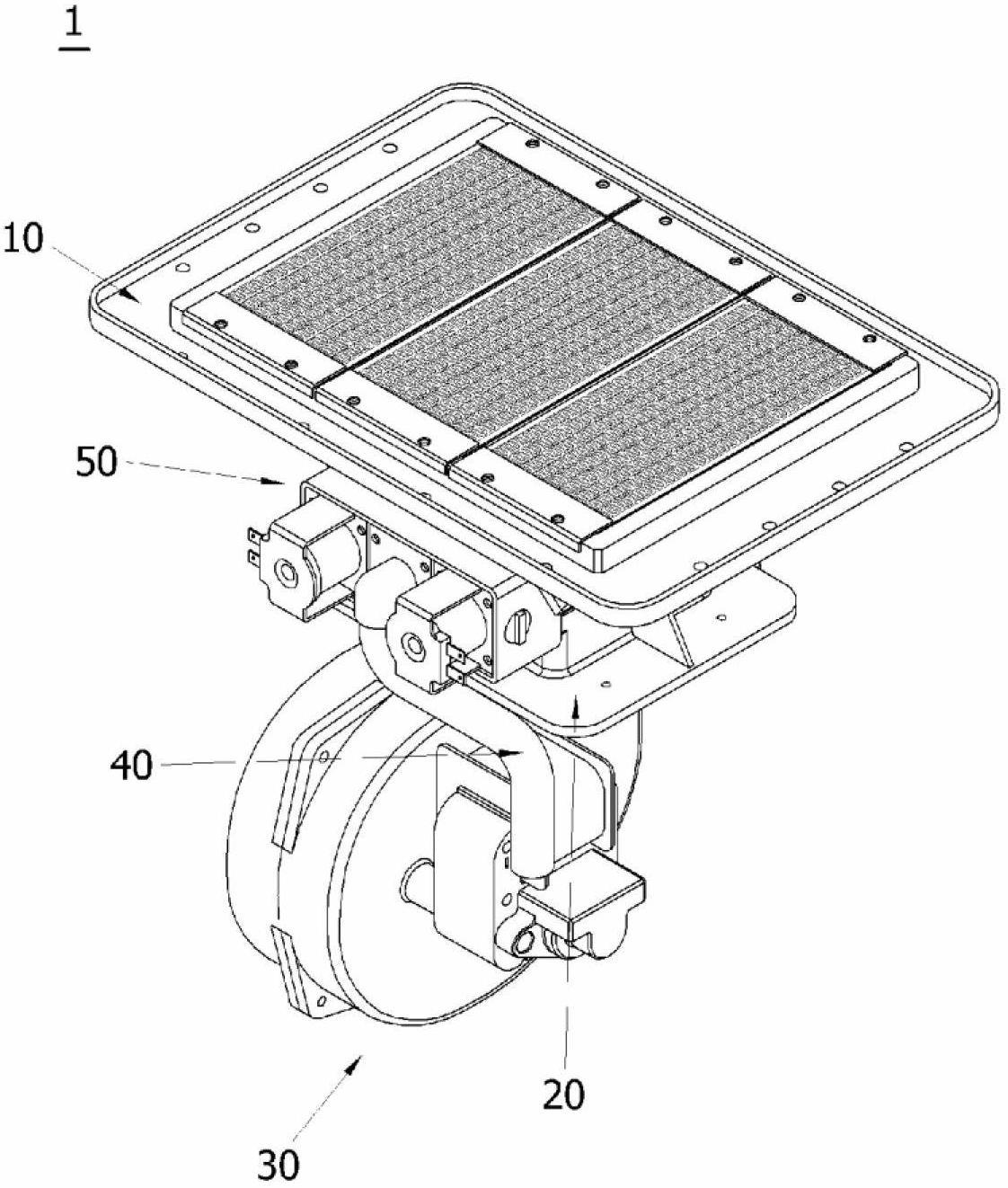

Flame hole unit structure of a gas burner

A technology of gas burners and flame holes, which is applied in the direction of gas fuel burners, burners, burners, etc., can solve the problems of increased manufacturing costs, incomplete combustion, and increased pressure loss, so as to reduce time and cost and prevent unsatisfactory Effect of complete combustion and reduced degree of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

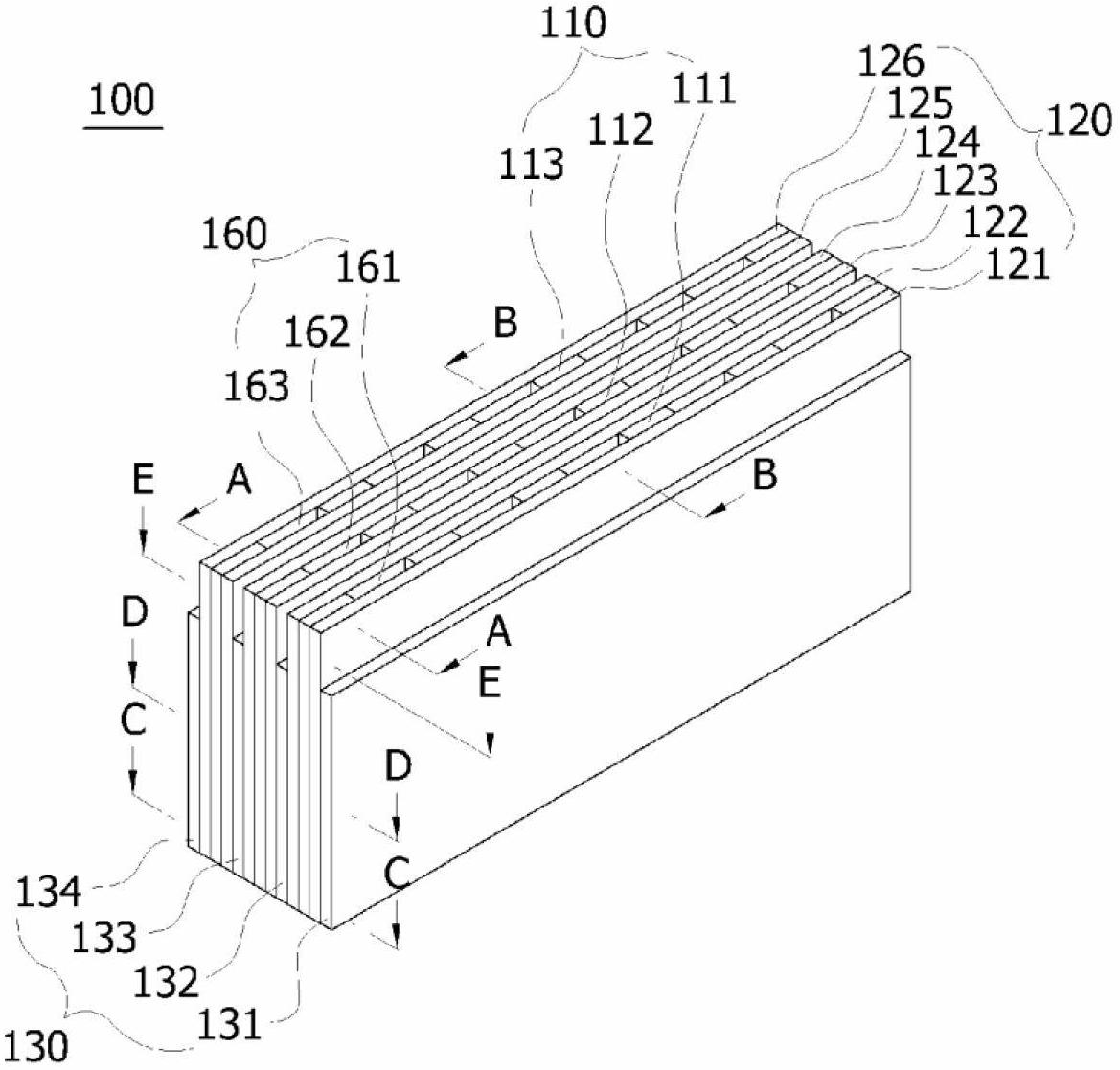

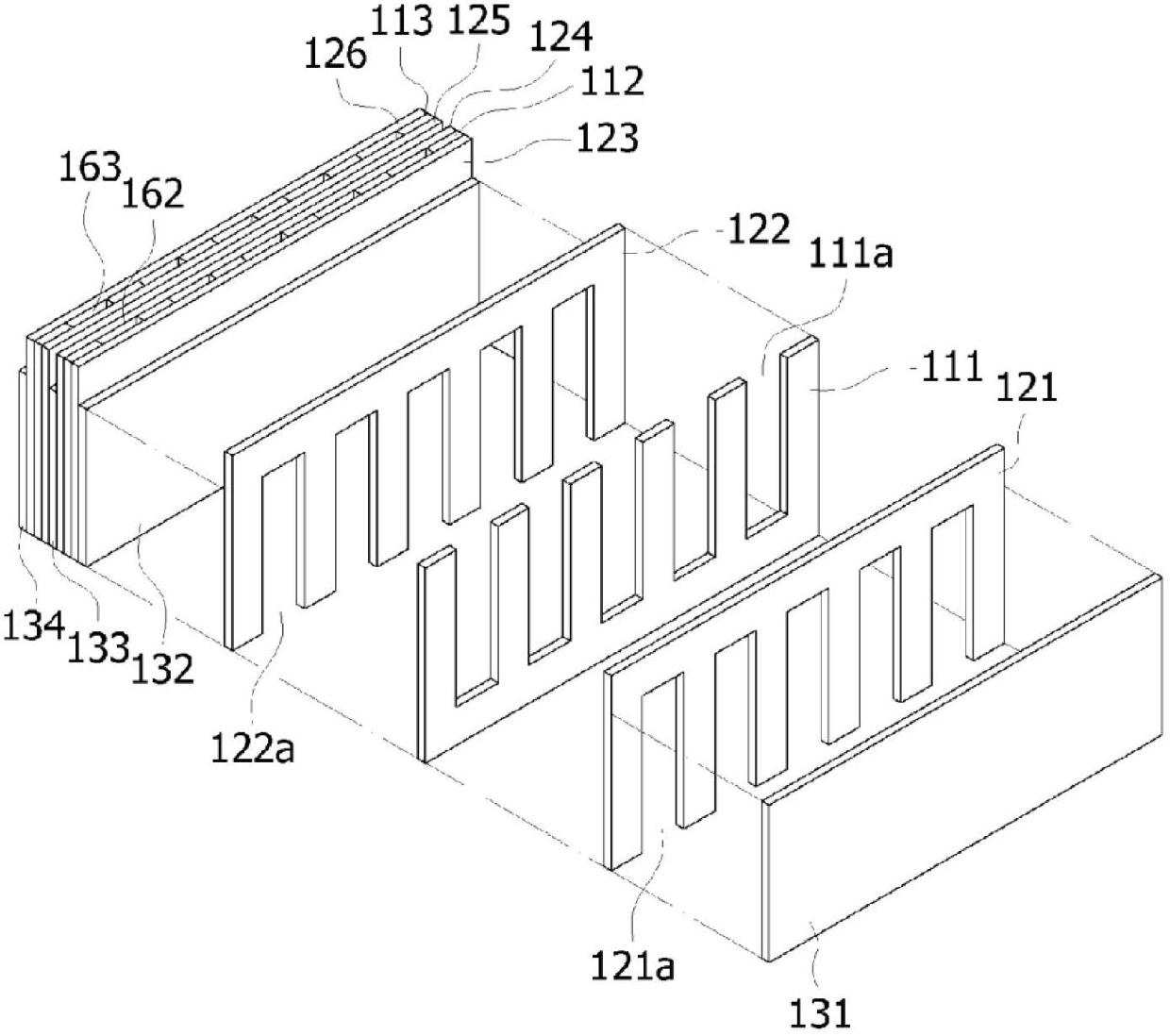

[0041] Hereinafter, the structures and functions of preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0042] figure 2 It is a perspective view of the flame hole structure of the gas burner of the present invention, image 3 for figure 2 Partial exploded perspective view of , Figure 4 for figure 2 The A-A line datum cross-section diagram, Figure 5 for figure 2 The B-B line datum section diagram, Image 6 for figure 2 The C-C line datum section diagram, Figure 7 for figure 2 The D-D line datum section diagram, Figure 8 for figure 2 E-E line datum section diagram.

[0043] The flame hole portion 100 of the gas burner of the present invention is characterized in that it is composed of a structure in which a plurality of thin plates are stacked and assembled, and a passage for the mixed gas of gas and air to move is formed on the inside of the stacked plates, and the passage is dredged to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com