Laser processing machine and bellows device

A laser processing machine, accordion technology, applied in auxiliary devices, laser welding equipment, metal processing equipment, etc., can solve problems such as damage, carbonization of accordion folds, openings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

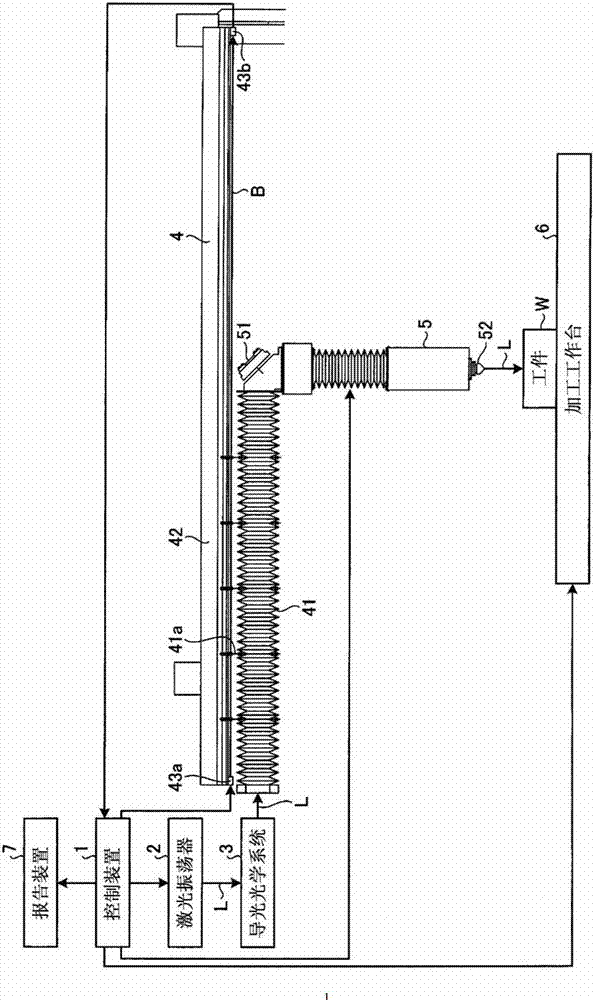

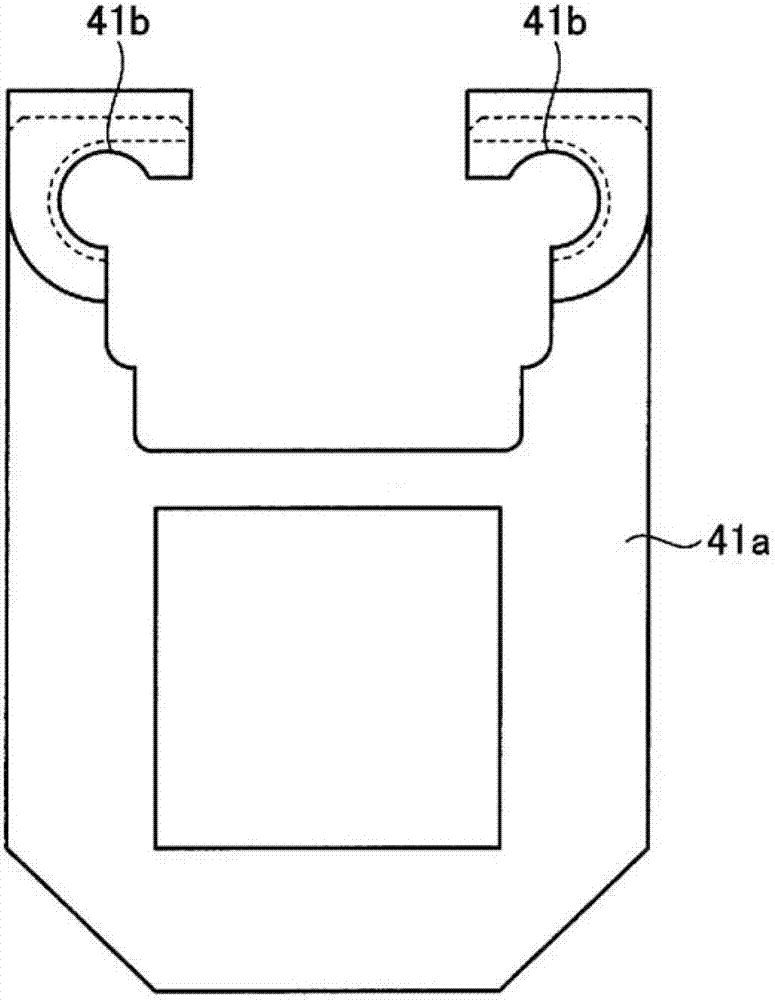

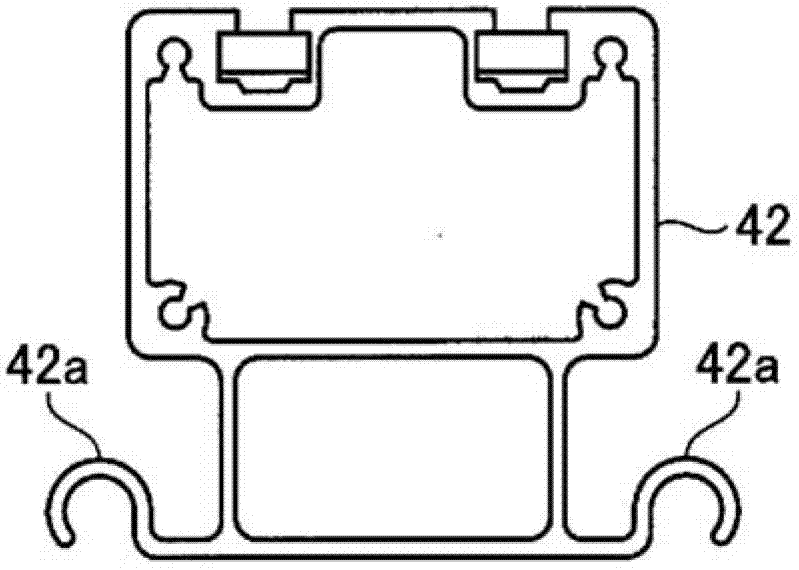

[0041] figure 1 It is a figure which shows the structure of Embodiment 1 of the laser processing machine concerning this invention. The laser processing machine includes a control device 1 , a laser oscillator 2 , a light guide optical system 3 , a bellows folding device 4 , a processing head 5 , a processing table 6 and a reporting device 7 . The laser processing machine propagates the laser light L emitted from the laser oscillator 2 along a predetermined optical path, and guides it to the workpiece W on the processing table 6 .

[0042] Laser oscillator 2 is CO 2 A device such as a laser that oscillates the laser light L emits the laser light L while varying the laser power during laser processing.

[0043] The light guide optical system 3 includes the following optical components not shown in the figure: a PR mirror, which partially reflects the laser light L emitted by the laser oscillator 2; a deflection mirror, which changes the beam of the laser light L transmitted f...

Embodiment approach 2

[0058] Figure 7 It is a figure which shows the structure of Embodiment 2 of the laser processing machine concerning this invention. The present embodiment is different from the first embodiment in that the beam sensor is provided not on the bellows movement guide 42 but on the bellows 41 .

[0059] In the present embodiment, the amount of light received by the beam sensor light receiving unit 43 b changes in accordance with the expansion and contraction of the bellows 41 , that is, the position of the processing head 5 . Therefore, the control device 1 corrects the amount of light received by the beam sensor light receiving section 43 b according to the position of the machining head 5 , and then judges the presence or absence of damage due to carbonization of the bellows 41 .

[0060] In other respects, since it is the same as that of Embodiment 1, repeated descriptions will be omitted.

[0061] In the present embodiment, since smoke can be detected over the entire length ...

Embodiment approach 3

[0063] Figure 8 It is a figure which shows the structure of Embodiment 3 of the laser processing machine concerning this invention. This embodiment differs from Embodiment 2 in that a beam sensor is provided inside the bellows 41 . That is, in the present embodiment, the light beam B emitted from the light beam sensor light emitting unit 43 a passes through the space inside the bellows 41 and reaches the light beam sensor light receiving unit 43 b.

[0064] When the reflected light from the workpiece W or the like enters the processing head 5 and irradiates the inner surface of the bellows 41, the bellows 41 is carbonized from the inside, and therefore, the smoke does not disappear until holes are opened in the bellows 41. Leaks out of the bellows 41 . Therefore, in the case where the beam sensor is provided outside the bellows 41 as in Embodiments 1 and 2 above, even if damage due to carbonization occurs inside the bellows 41 , holes cannot be opened in the bellows 41 . d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com