Fluid ejection device

A fluid injection and fluid technology, applied in fire rescue and other directions, can solve problems such as the influence of the reliability of the sealing element device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

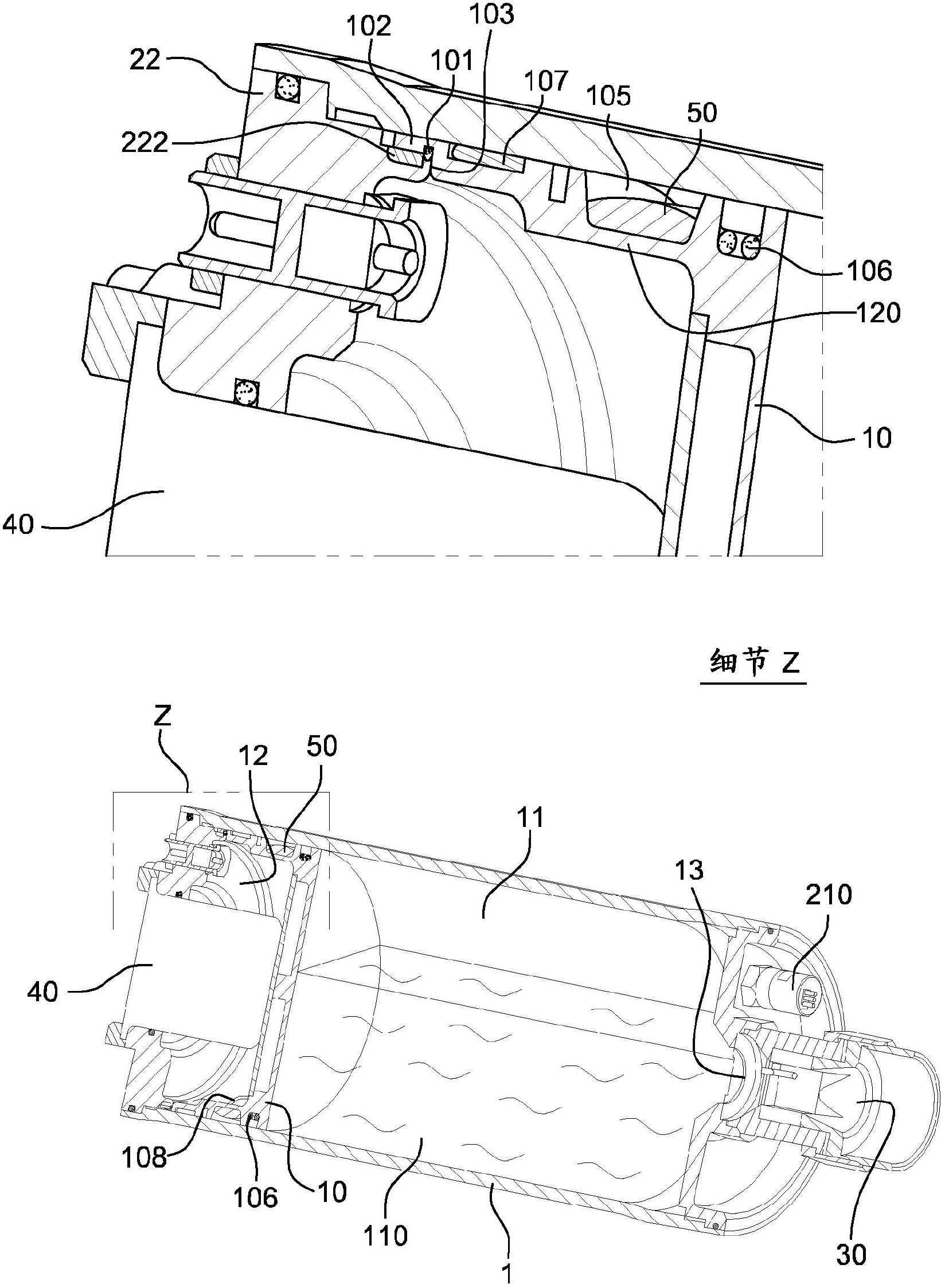

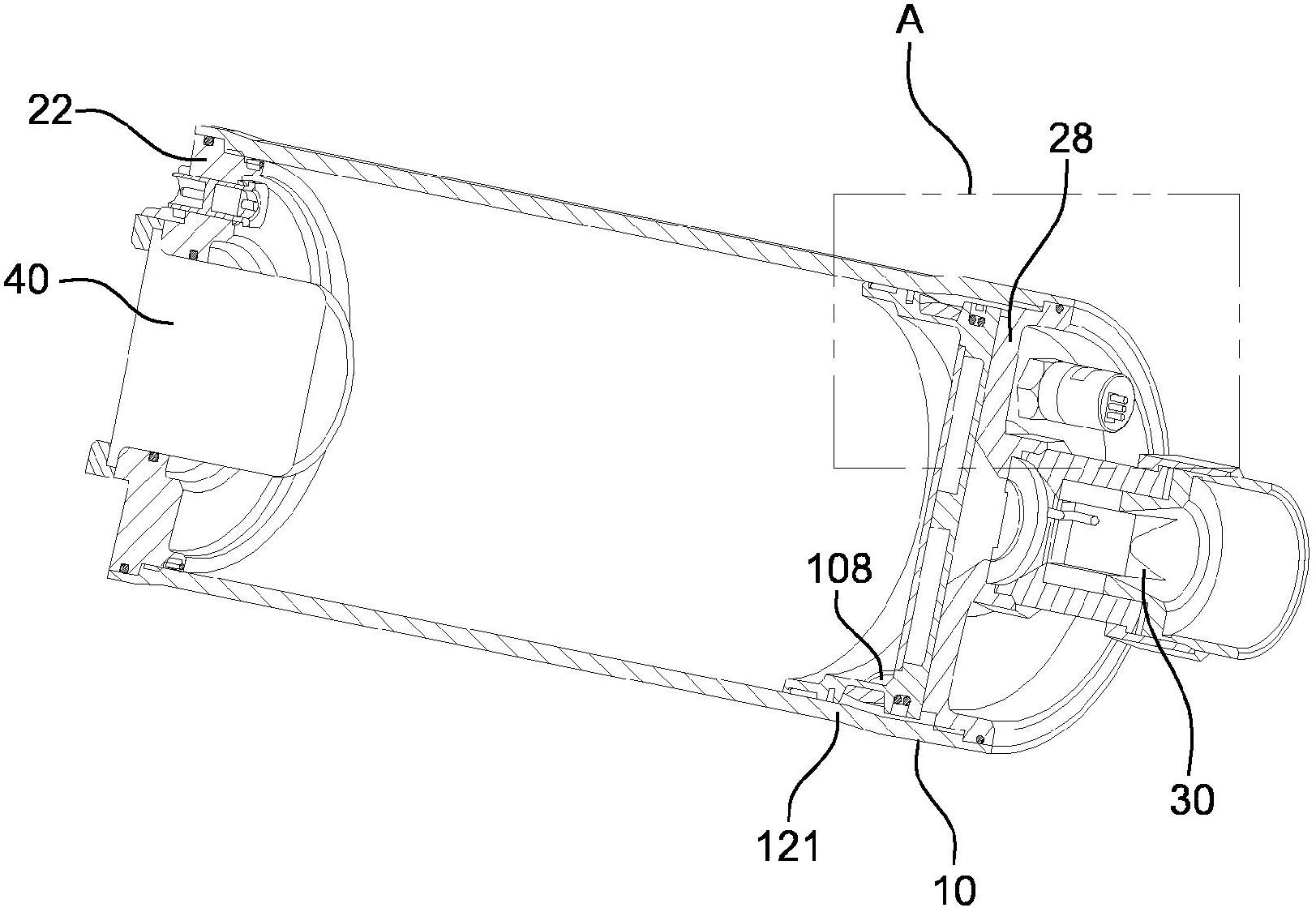

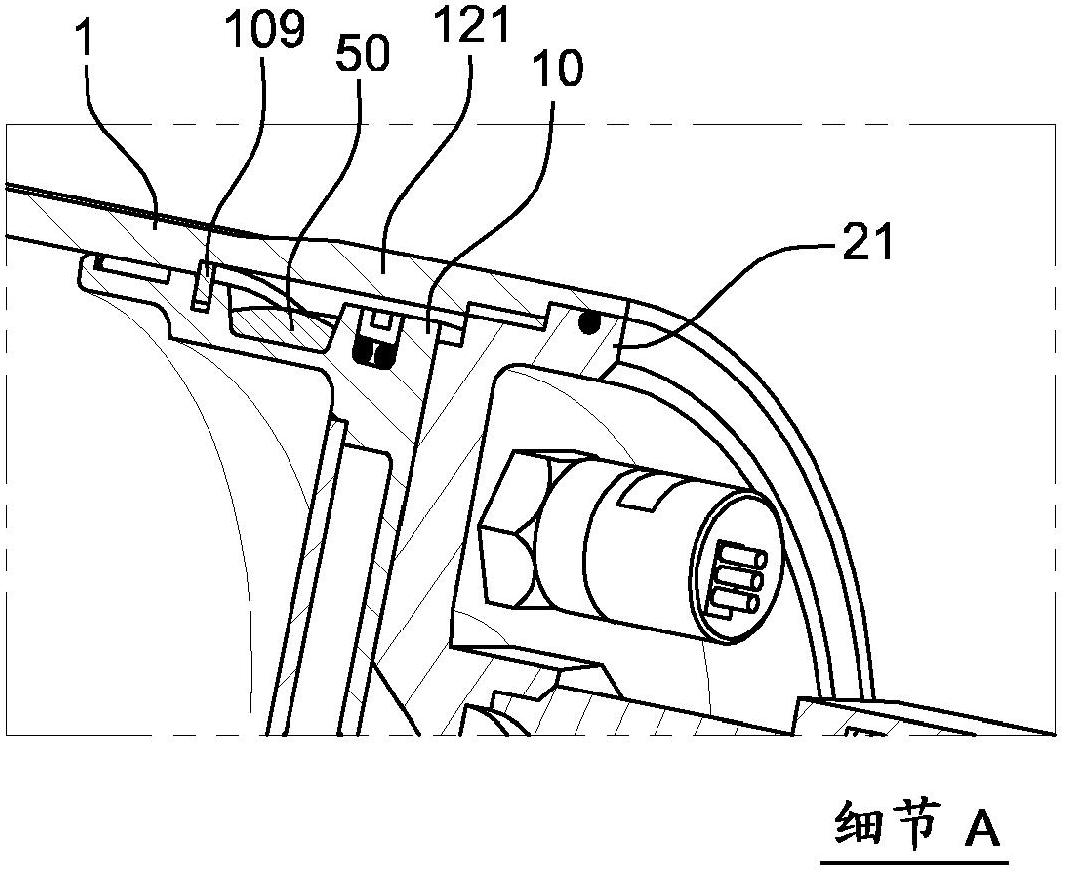

[0031] figure 1 : According to an embodiment, the fluid ejection device which is the subject of the invention comprises a cylindrical body (1) divided by a piston (10) into two chambers (11, 12) and at its end Closed by two flanges (21, 22). The first chamber ( 11 ) is partially filled with the fluid to be injected ( 110 ); the remainder of the volume is filled with an inert gas so that the pressure inside this chamber is always higher than atmospheric pressure. This first chamber communicates with an orifice ( 13 ) formed in the end flange ( 21 ), the orifice ( 13 ) being closed by a removable cap ( 30 ). The airtightness of the first chamber can be checked with means (210) for measuring the pressure in the first chamber. The second chamber (12) (called "plenum chamber") is also closed by a flange (22) which also supports a device (40), which in this case is a pyrotechnic gas A generator designed to increase the pressure in the chamber.

[0032] figure 1 Detail Z: The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com