Backlight module and rubber frame structure thereof

A technology for a backlight module and a plastic frame is applied in the field of the backlight module and its plastic frame structure, and can solve the problems of inability to apply, no shared flexibility, high cost of mold opening and mold, and high cost of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

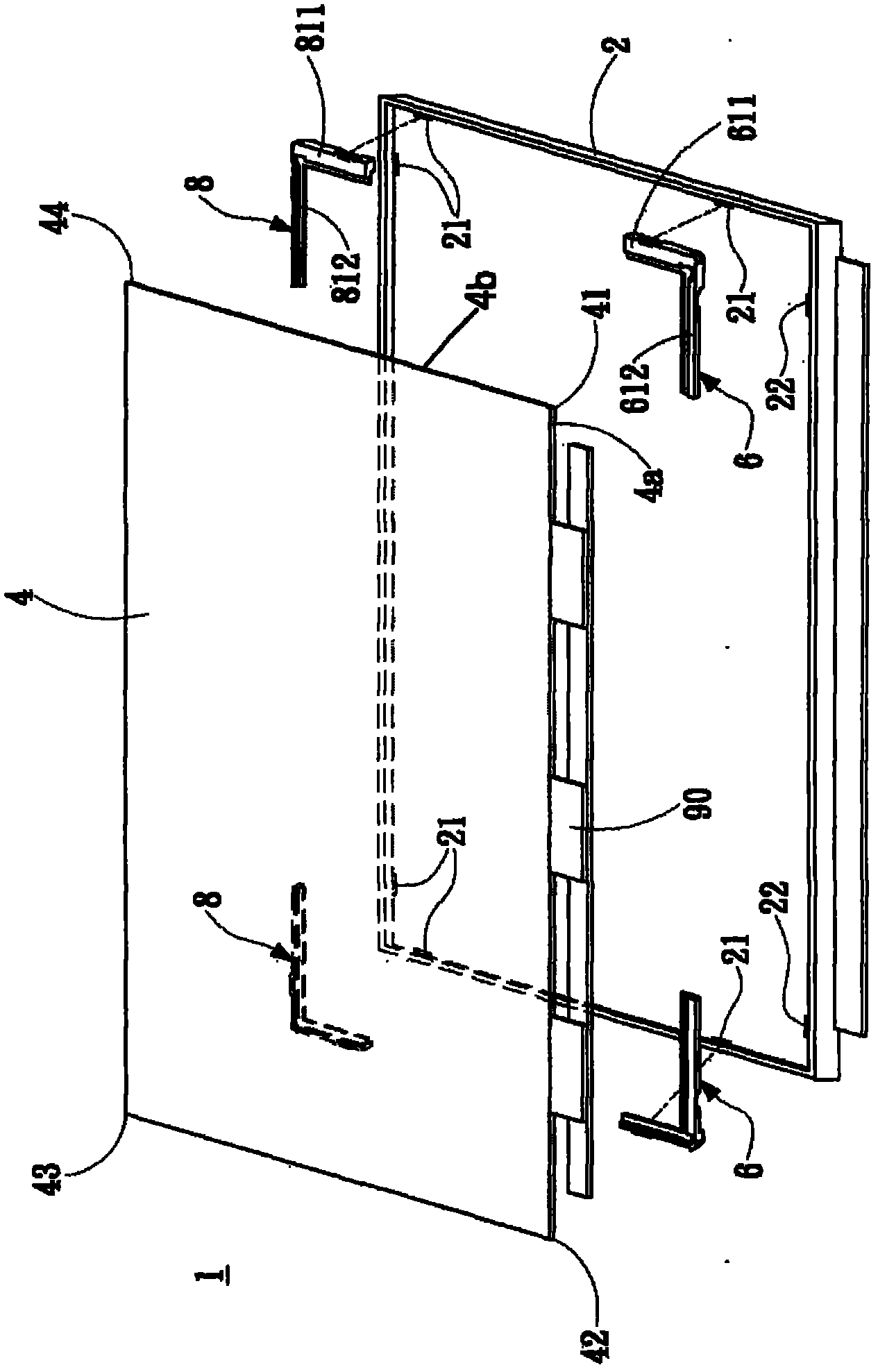

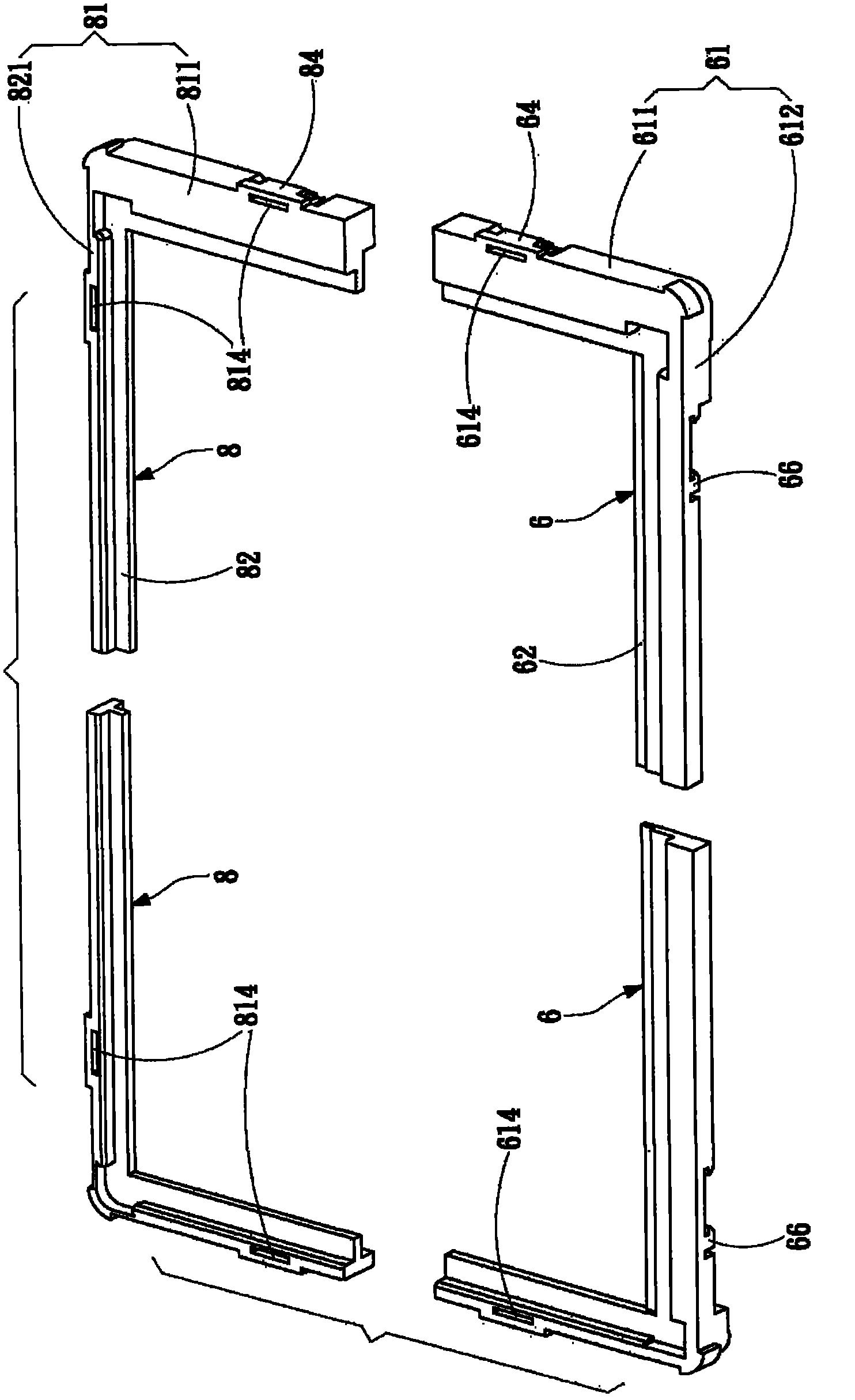

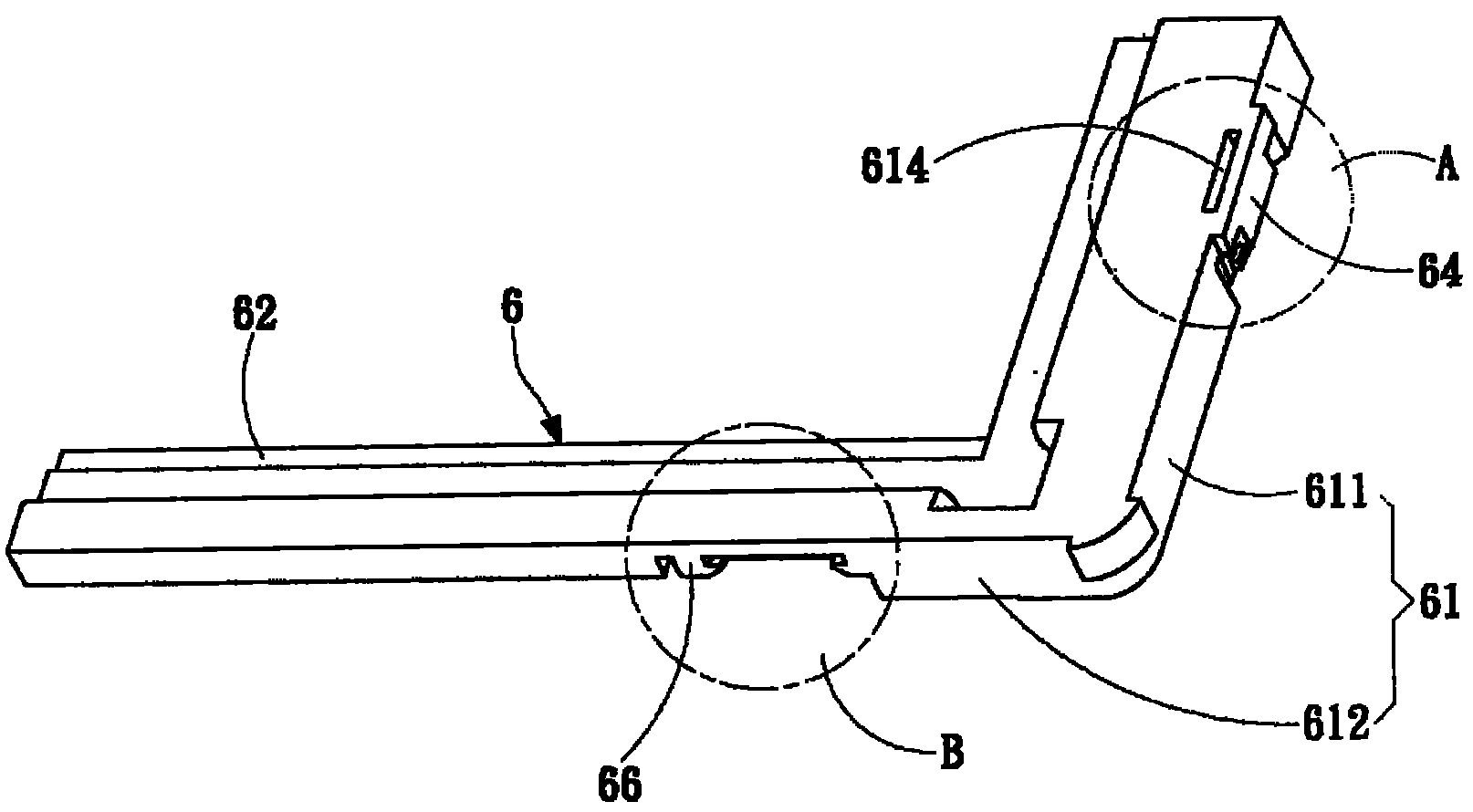

[0066] figure 1 , figure 2 , Figure 3A , Figure 3B , Figure 3C , Figure 4A and Figure 4B The backlight module of the present invention is shown.

[0067] The backlight module 1 includes: a backplane 2 , a light guide plate 4 , two first frames 6 , and two second frames 8 .

[0068] The backboard 2 is generally a rectangular hollow body, preferably made of metal, or made of plastic or other suitable materials. Here, the backboard 2 is provided with a plurality of first positioning pieces 21 on three connected frames of the rectangle respectively, and a plurality of second positioning pieces 22 are provided on the other fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com