Multifunctional water softening valve

A soft water valve, multi-functional technology, applied in multi-way valves, valve devices, descaling and water softening, etc., can solve the problem of inconsistent width of flow channels inside the valve body, and achieve the effect of smooth water flow and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: The technical solution of directly discharging sewage from the cover through the valve stem is adopted.

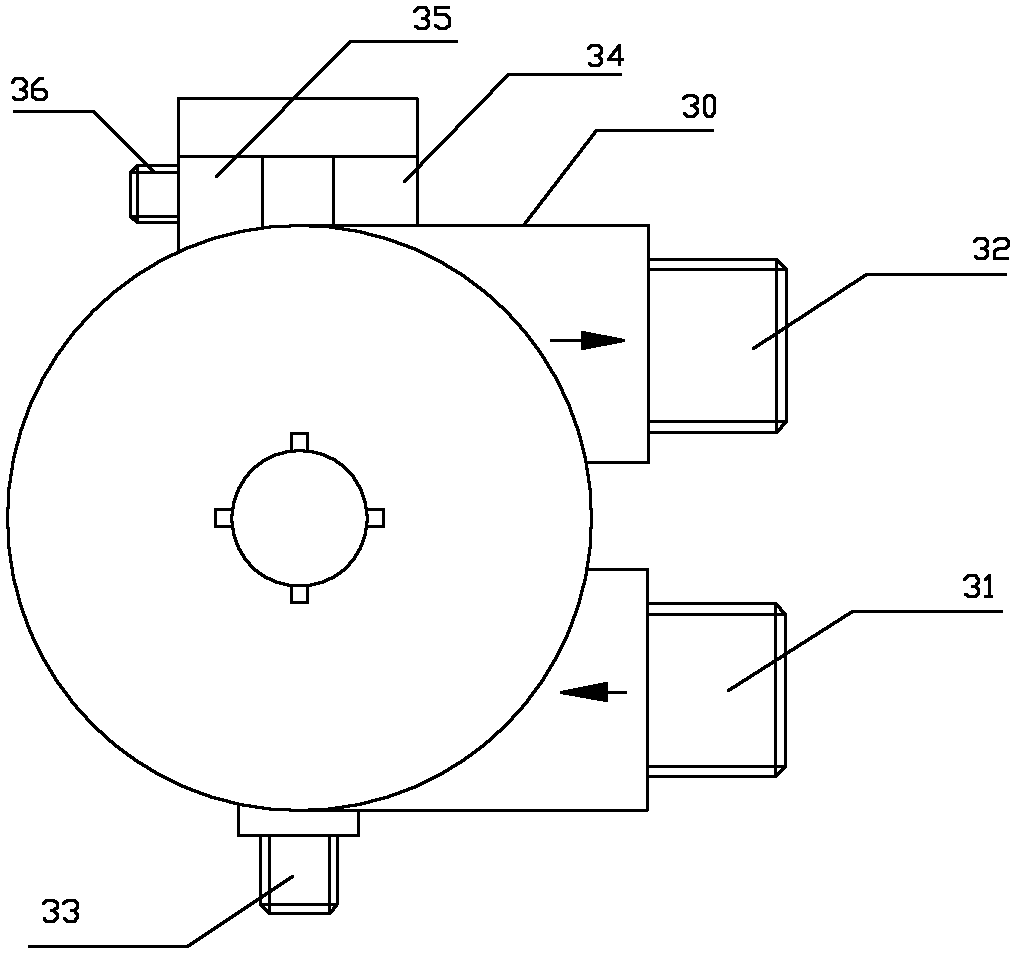

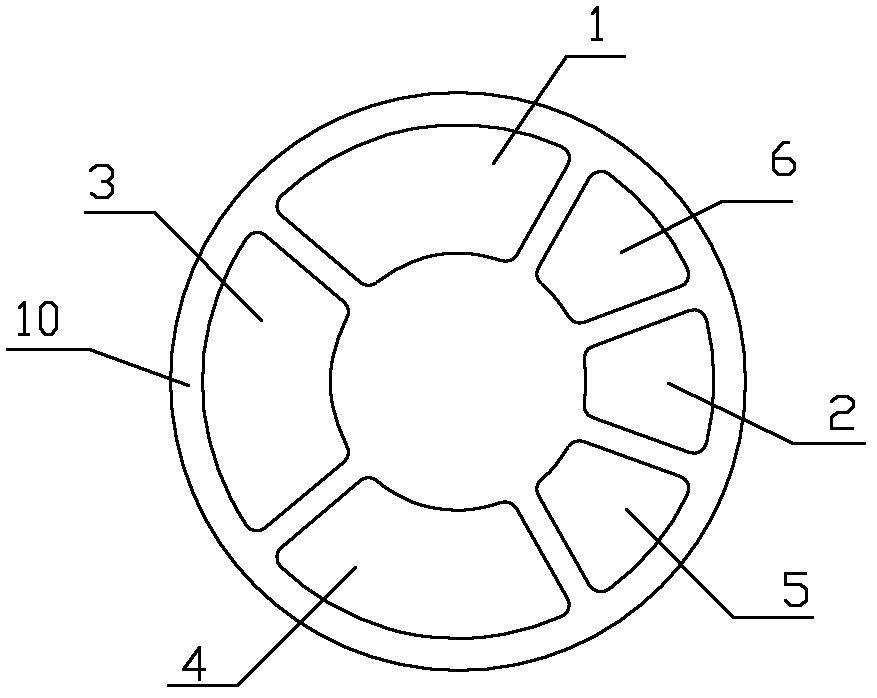

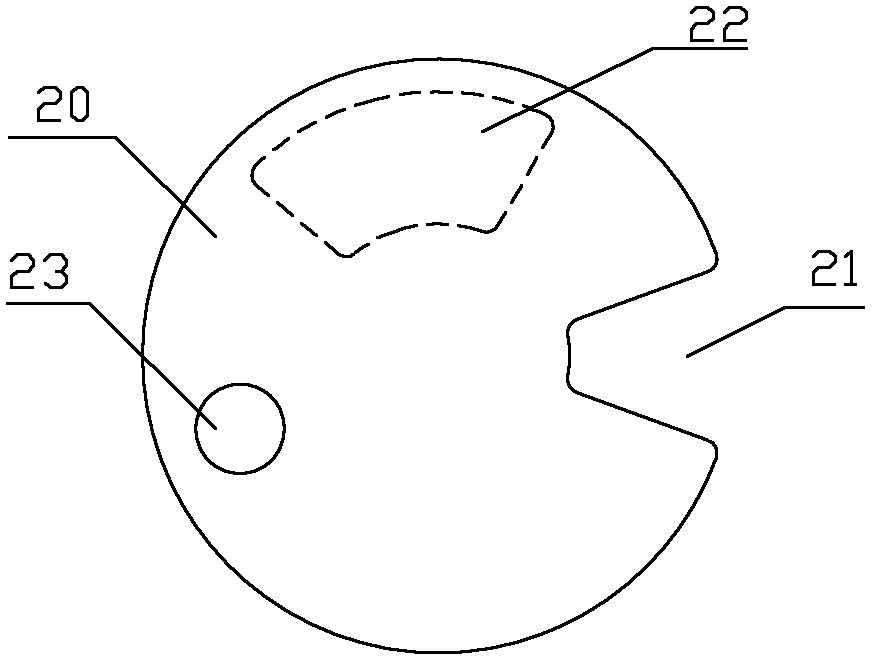

[0043] As shown in Figures 1-4, in Example 1, use figure 2 and image 3 The combination of fixed and moving valve slices shown. A multi-functional soft water valve, including a valve body 30, a cover 60, an ejector 37, a fixed valve plate 10 and a movable valve plate 20, a movable valve plate 20 and a valve stem 61 placed in the valve body 30 and adopting end face rotation and sealing fit connected, the valve body 30 is provided with a water inlet 31, a water outlet 32, an ejector outlet 34, an ejector inlet 35, a filter element outer interface 38 and a filter element inner interface 39, and the ejector 37 passes through the ejector outlet 34 and the ejector inlet 35 It communicates with the valve body, the ejector 37 is provided with a salt suction port 36, the sewage discharge port 33 is provided on the cover 60, and the fixed valve plate 10 is pro...

Embodiment 2

[0050] Embodiment 2: The technical scheme of blowing down through the valve stem to the cover and then to the valve body is adopted.

[0051] Such as Figure 14 As shown, the fixed valve plate 10 is provided with a sewage discharge through hole 23, and the sewage discharge port 233 is arranged on the valve body. The hole 64 communicates with the drain port 233 on the valve body 30 .

[0052] The difference between Embodiment 2 and Embodiment 1 is that the sewage outlet of Embodiment 1 is set on the cover, and the channel for sewage discharge is: through the sewage discharge through hole and then through the first sewage discharge through hole on the valve stem and the cover in turn. The second drain hole on the cover is connected to the drain port on the cover. Other instructions are similar and will not be repeated here.

Embodiment 3

[0053] Embodiment 3: The technical scheme of blowing down through the seventh through hole of the fixed valve plate and then to the valve body is adopted.

[0054] Such as Figure 15-18 Shown, in embodiment three, use Figure 16 and Figure 17 The combination of fixed and moving valve slices shown. A multi-functional soft water valve, including a valve body 30, a cover 60, an ejector 37, a fixed valve plate 10 and a movable valve plate 20, a movable valve plate 20 and a valve stem 61 placed in the valve body 30 and adopting end face rotation and sealing fit connected, the valve body 30 is provided with a water inlet 31, a water outlet 32, an ejector outlet 34, an ejector inlet 35, a filter element outer interface 38 and a filter element inner interface 39, and the ejector 37 passes through the ejector outlet 34 and the ejector inlet 35 It communicates with the valve body, a salt suction port 36 is set on the jet 37, a sewage discharge port 333 is set on the valve body 30, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com