Well structure for delaying casing damage on fault

A technology of wellbore structure and faults, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve problems such as failure to prevent fault slippage, casing damage at faults, failure to prevent fault shear slippage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific examples.

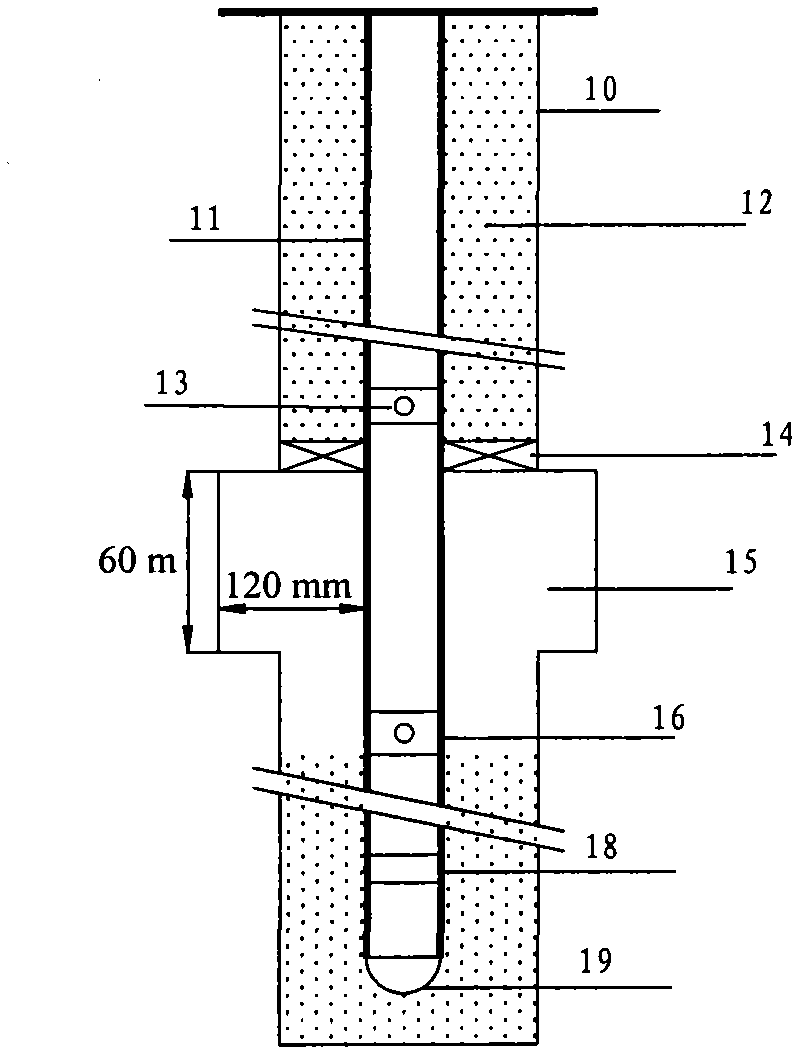

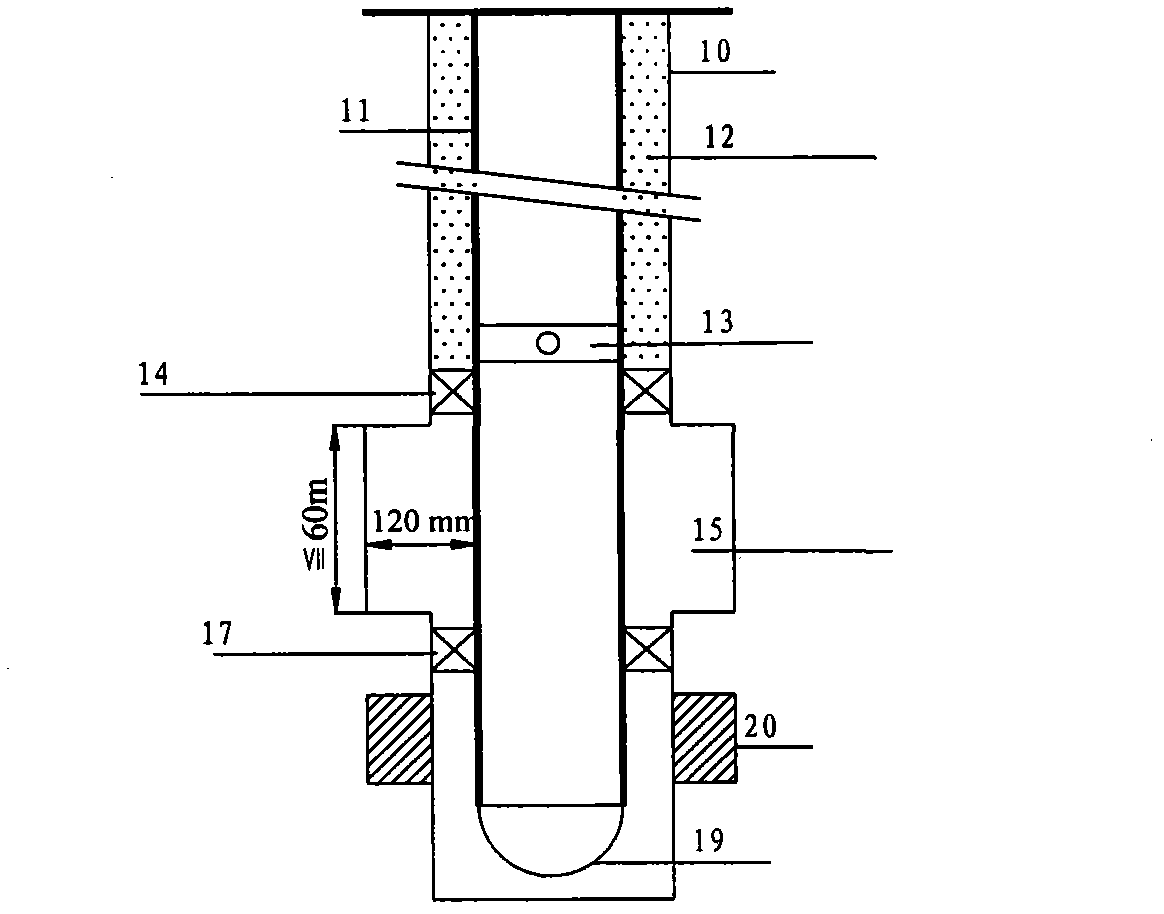

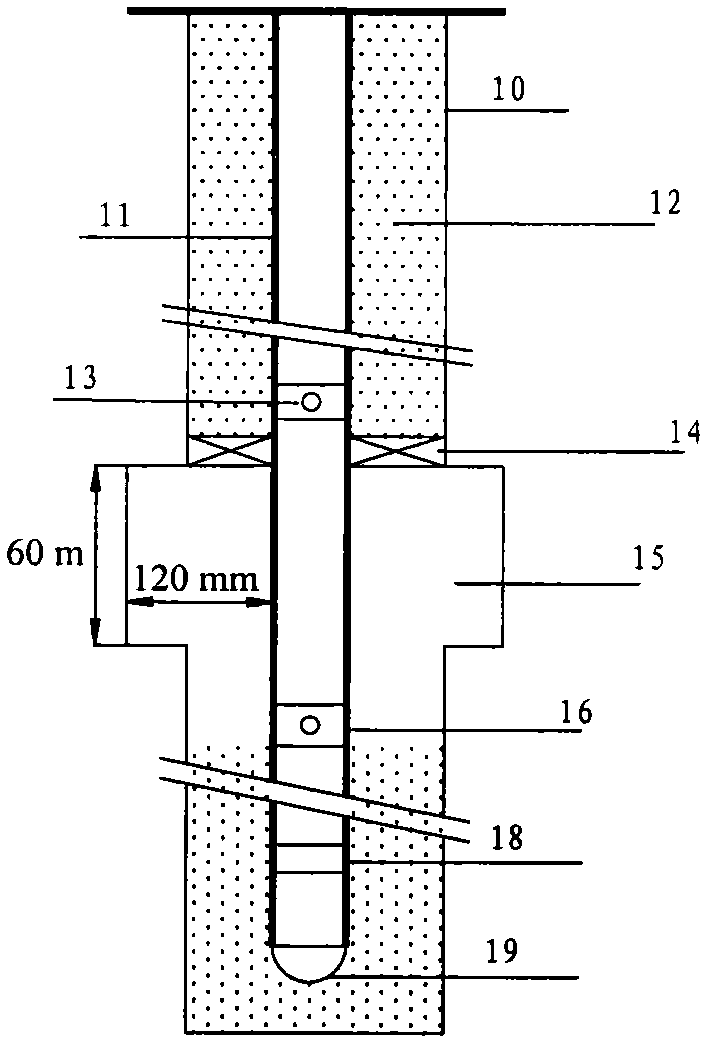

[0015] In order to delay casing damage at faults, the present invention proposes a new wellbore structure for drilling at faults: no cementing in the 30m interval above and below the breakpoint encountered in drilling, and reaming while drilling is adopted to make the gap between the casing and the formation The gap reaches 120mm, leaving a buffer zone for the movement of the formation along the fault to prevent the casing from being sheared and damaged.

[0016] 1. Reaming operation

[0017] Considering the risk and cost of reaming comprehensively, it is proposed to use the reaming-while-drilling technology to ream the interval 30m above and below the breakpoint.

[0018] Reaming-while-drilling construction process: Before the tool enters the well, ensure that the reaming-while-drilling bit can be retracted freely → lower the reaming-while-drilling tool to the predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com