Tread rubber composition for semisteel meridian snow tire used in extremely cold area

A rubber composition and technology for snow tires, applied in the field of rubber, can solve the problems that all-season tires cannot meet the subdivision requirements and reach below minus 40 degrees, and achieve the effect of improving ice grip performance and outstanding cold resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

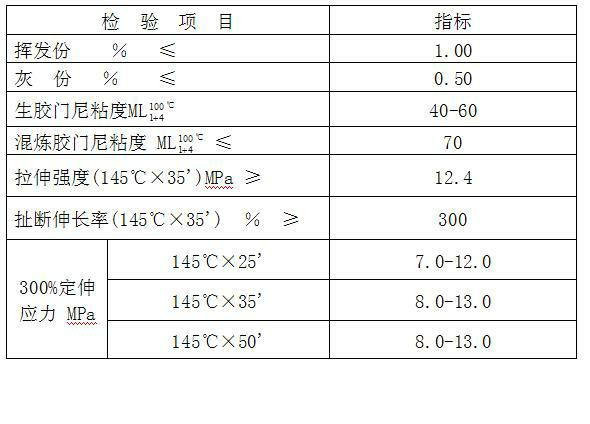

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention will be further described:

[0019] The rubber mixture involved in the present invention includes modified styrene-butadiene rubber, natural rubber and polybutadiene rubber.

[0020] The modified styrene-butadiene rubber described in the invention has a combined styrene content of 15-30% by mass and a solution-polymerized styrene-butadiene rubber with a vinyl content of 10-50% by mass; such as Asahi Kasei Corporation of Japan TUF1534; HP-340 from Japan JSR Synthetic Rubber Company, etc.

[0021] In the invention, the solution polymerized styrene-butadiene rubber SSBR, in order to ensure a certain processing performance, can be preferably oil-extended SSBR; non-oil-extended SSBR can also be used, and the usage amount of the corresponding rubber processing softener should be properly adjusted when using .

[0022] The type of extender oil for oil-extended SSBR is TDAE (Treated Distillate Aromatic Extract treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com