Insoluble sulfur stabilizing agent and preparation method thereof

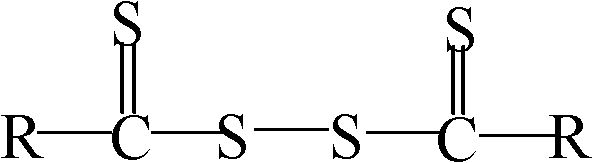

A sulfur stabilizer and solubility technology, applied in the preparation/purification of sulfur, etc., can solve the problems of poor thermal stability of insoluble sulfur, poor dispersion effect of insoluble sulfur, expensive synthetic raw materials, etc., and achieve high stabilization effect, low price, and synthetic low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.10mol sodium isoamyl xanthate to 80ml ethanol, start stirring after dissolving, and add 0.20mol CuSO dropwise under stirring 4 , Reacted in a water bath at 75°C for 3h. After the reaction is complete, extract with 120ml of carbon disulfide for 3 to 4 times, and distill the carbon disulfide out under atmospheric pressure after the extraction is complete. Then dry the liquid in the flask at a constant temperature of 60°C for 30-50 minutes. After drying, cool to obtain a light yellow oily liquid, weigh it, and calculate the yield.

Embodiment 2

[0027] Add 0.10mol potassium diethyldithiocarbamate to 120ml water, start stirring after dissolving, and add 0.15mol FeCl drop by drop under stirring 3 , and reacted in a water bath at 45°C for 5h. After the reaction is complete, extract with 120ml of carbon disulfide for 3 to 4 times, and distill the carbon disulfide out under atmospheric pressure after the extraction is complete. Then dry the liquid in the flask at a constant temperature of 60°C for 30-50 minutes. After the drying is completed, a light yellow oily liquid is obtained, which is cooled and weighed to calculate the yield.

Embodiment 3

[0029] Add 0.15mol O-(2-ethylhexyl)potassium dithiocarbonate to 140ml acetone, start stirring after dissolving, and add 0.15mol H 2 o 2 , and reacted in a water bath at 30°C for 6h. After the reaction is complete, extract with 120ml of carbon disulfide for 3 to 4 times, and distill the carbon disulfide out under atmospheric pressure after the extraction is complete. Then dry the liquid in the flask at a constant temperature of 60°C for 30-50 minutes. After the drying is completed, a light yellow oily liquid is obtained, which is cooled and weighed to calculate the yield.

[0030] The product yield analysis result in embodiment 1~3 sees the following table:

[0031] Product yield in each embodiment of table 1

[0032]

[0033] The results in the above table show that this type of stabilizer has a higher yield under their respective synthesis conditions.

[0034] Performance evaluation of the target product:

[0035] The stabilizers prepared in Examples 1-3 were applied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com