Aluminum discharge vehicle

A technology for aluminum-extruding vehicles and wheels, which is applied to vehicle parts, lifting devices, and lower structures, and can solve problems such as adverse health effects of operators, operational errors, and unreliable actions, and achieve the goal of overcoming the impact of equipment action accuracy and reducing The effect of improving the probability of operation errors and the flexibility of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

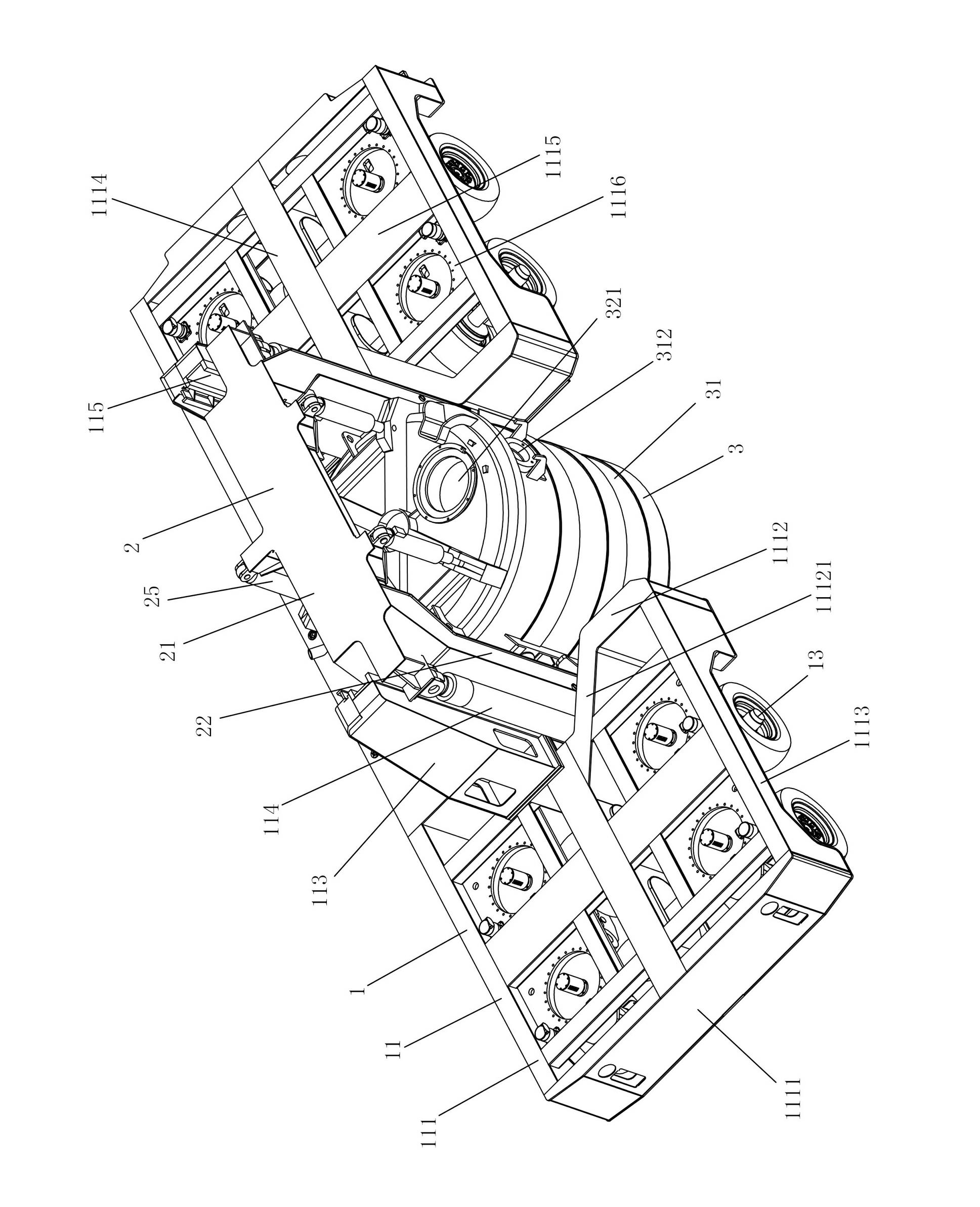

[0023] Figure 1 to Figure 6 It shows an embodiment of an aluminum tapping car of the present invention, including a vehicle chassis 1, a door frame 2, and a ladle 3, and adopts a structure in which the vehicle chassis 1 is equipped with a door frame 2 and a ladle 3, so that the aluminum tapping car can move flexibly The performance is greatly improved, and the adaptability is strong. In the same electrolysis workshop, multiple aluminum tapping vehicles of the present invention can be used simultaneously to carry out aluminum tapping operations, thereby greatly improving the efficiency of aluminum tapping operations; form, the present invention reduces the height of the ladle 3 from the ground, and the safety can be effectively guaranteed, and can overcome the influence of the strong magnetic field in the electrolysis workshop on the accuracy of the equipment, greatly reducing the probability of operating errors, and further improving safety; the vehicle chassis 1 includes veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com