Batch punching punch for perforator

A technology of punching machine and punch, applied in punching tools, metal processing, metal processing equipment, etc., can solve problems such as slow punching rate and inability to meet product requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

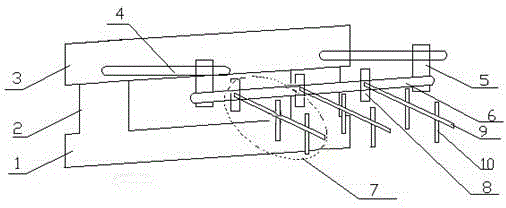

[0011] figure 1 The batch punching head of a punching machine shown includes a support 1, a guide post 2 is arranged above the support 1, a template 3 is provided above the guide post 2, and a fixed post 4 is provided on the template 3, The other end of the fixed column 4 is provided with a laterally moving slider 5, a lateral guide rail 6 is provided below the laterally movable slider 5, and a punch module 7 is arranged on the lateral guide rail 6, and the punch module 7 includes a punch A head fixing block 8, the punch fixing block 8 is provided with a punch guide rail 9, the punch guide rail 9 is provided with a punch 10, the punch module is not less than 1, and the punch module has 3.

[0012] After adopting the above structure, its characteristics are: move the template 3 up and down before punching to adjust the depth of the holes on the product, move the slider 5 back and forth and laterally to adjust the left and right distances of the holes on the material, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com