Combined jig with overturn function

A combined fixture and function technology, applied in the field of combined fixtures with flip function, can solve problems such as affecting operation, occupying a lot of space, and different fixture structures, reducing labor intensity, saving space, and reasonable structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The combined jig with flip function provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

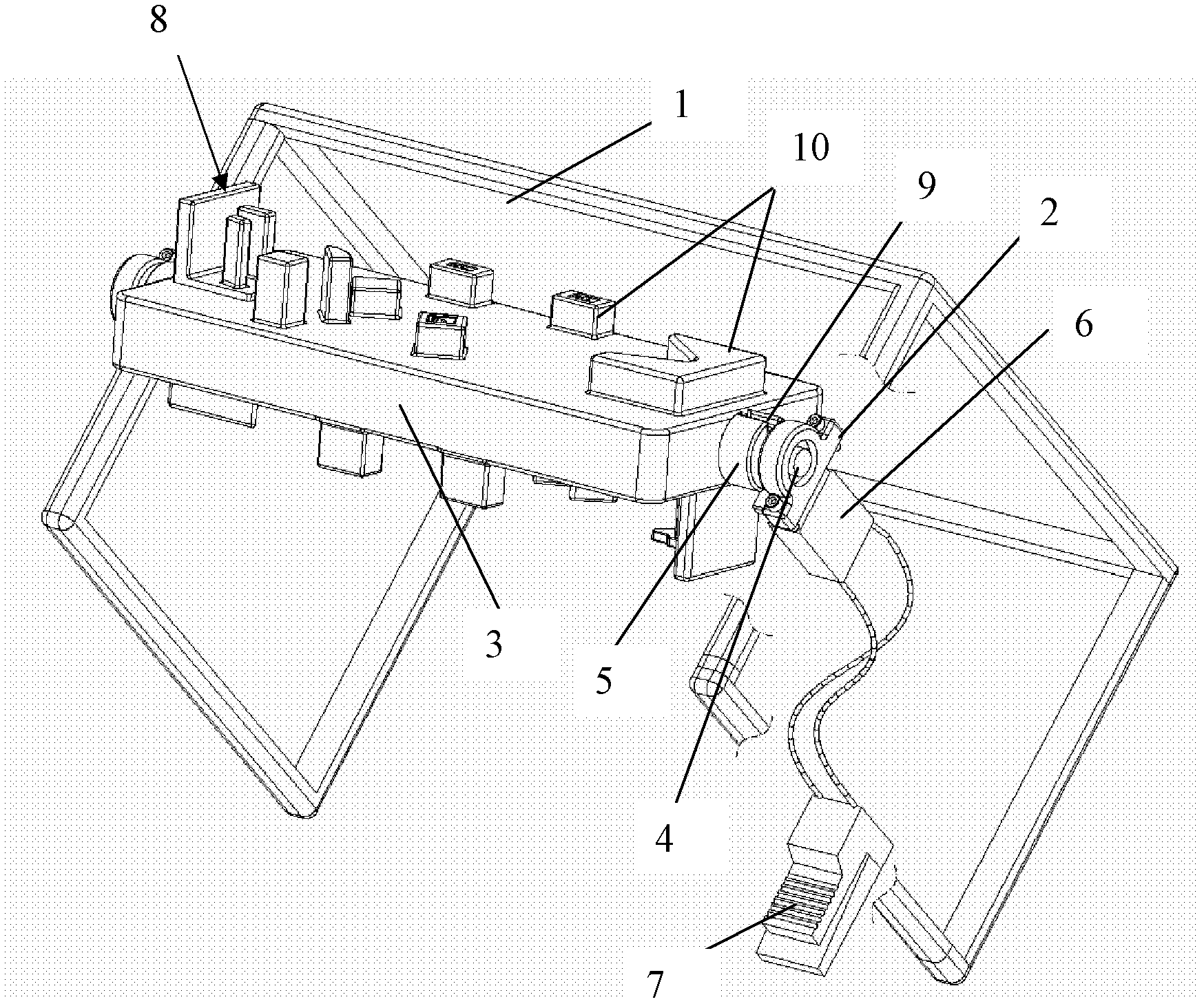

[0010] Such as figure 1 As shown, the combined jig provided by the present invention includes a bracket 1, two bearings 2, a base plate 3, a rotating shaft 4, a limit block 5, a pneumatic positioning pin 6, a pedal 7 and two sets of jigs 8; The lower end of the bracket 1 is set on the ground; two bearings 2 are symmetrically installed on both sides of the bracket 1; the base plate 3 is rectangular; The two ends of 4 are installed on two bearings 2 respectively; the limit block 5 is annular, and is set on the rotating shaft 4 between one end of the base plate 3 and the adjacent bearing 2, and its outer circumferential surface is along the length A limit groove 9 is formed in the direction; a pneumatic positioning pin 6 that can lock or release the upper limit groove 9 of the limit block 5 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com