Bandage fixed-length feeding system and method

A feeding system and fixed-length technology, applied in bandages, sending objects, thin material processing, etc., to achieve the effect of improving feeding efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

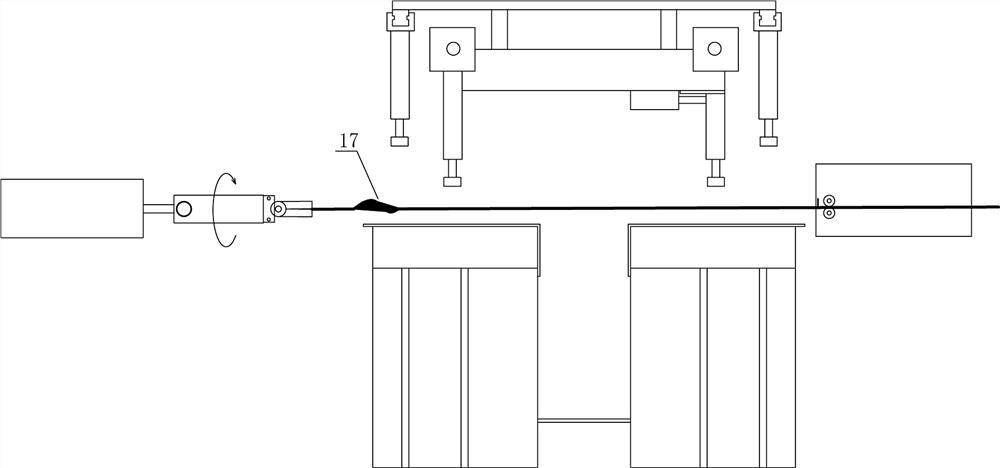

[0039] The preferred solution is as Figure 1 to Figure 9 As shown, a bandage fixed-length feeding system and method includes a workbench 9, one end of the workbench 9 is provided with a fixed-length cloth feeding and cutting mechanism 2, and the other end of the workbench 9 is provided with a fixed-length retrieving and turning mechanism 3, and the workbench 9 The top is provided with a transfer arm mechanism 4; the fixed-length cloth feeding and cutting mechanism 2 is used to pull the bandage 10 and cut the bandage 10 to form a bandage 11 to be sewn; the fixed-length retrieving and turning mechanism 3 includes a chuck 301, and the chuck 301 is installed on the One end of the rotating head 302, the chuck 301 is used to clamp the bandage 10, and the rotating head 302 is driven by the chuck direct drive device 303 to perform translation and expansion; the transfer arm mechanism 4 includes a hanger 407, and the hanger 407 is provided with a downward pressure translation mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com