Hydraulic power unit including centrifugal pump and vane pump in motor

A technology of hydraulic power unit and vane pump, which is applied in the direction of machine/engine, pump, pump device, etc., can solve the problems of high noise of hydraulic power unit, complex hydraulic power unit, insufficient oil absorption, etc., and achieves reliable sealing, compact structure, and elimination of Effects of Aerodynamic Noise and Cavitation Noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

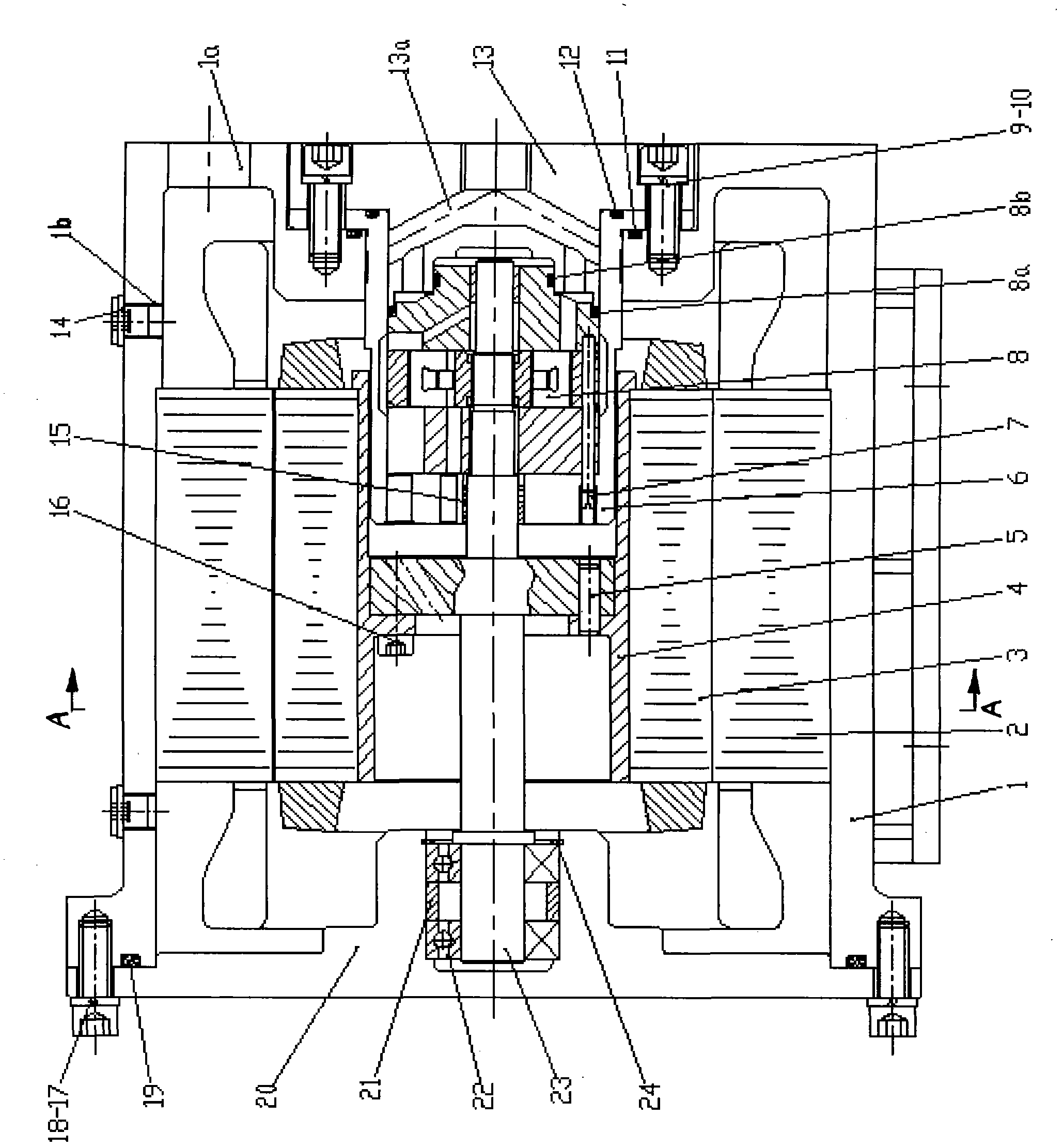

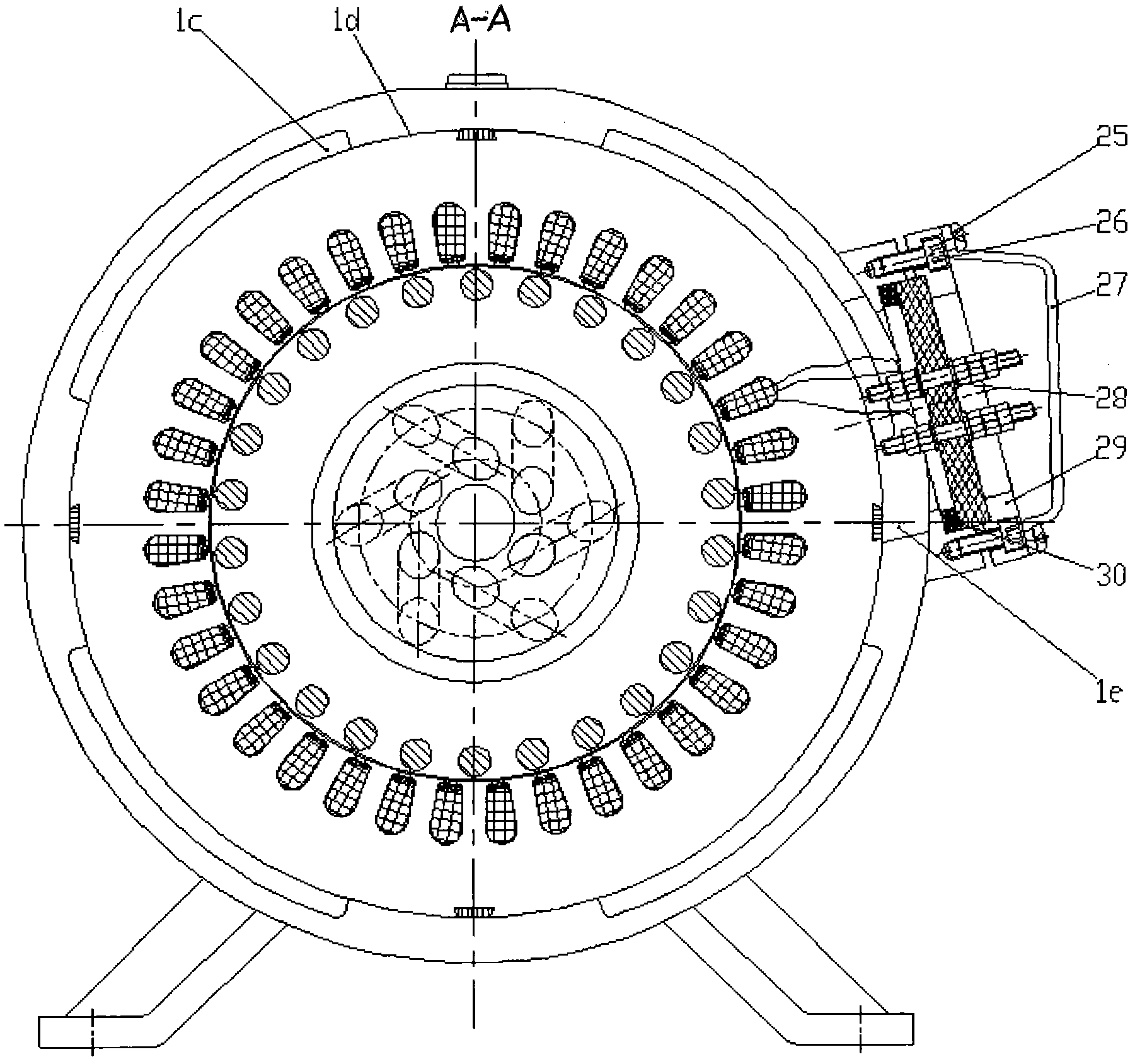

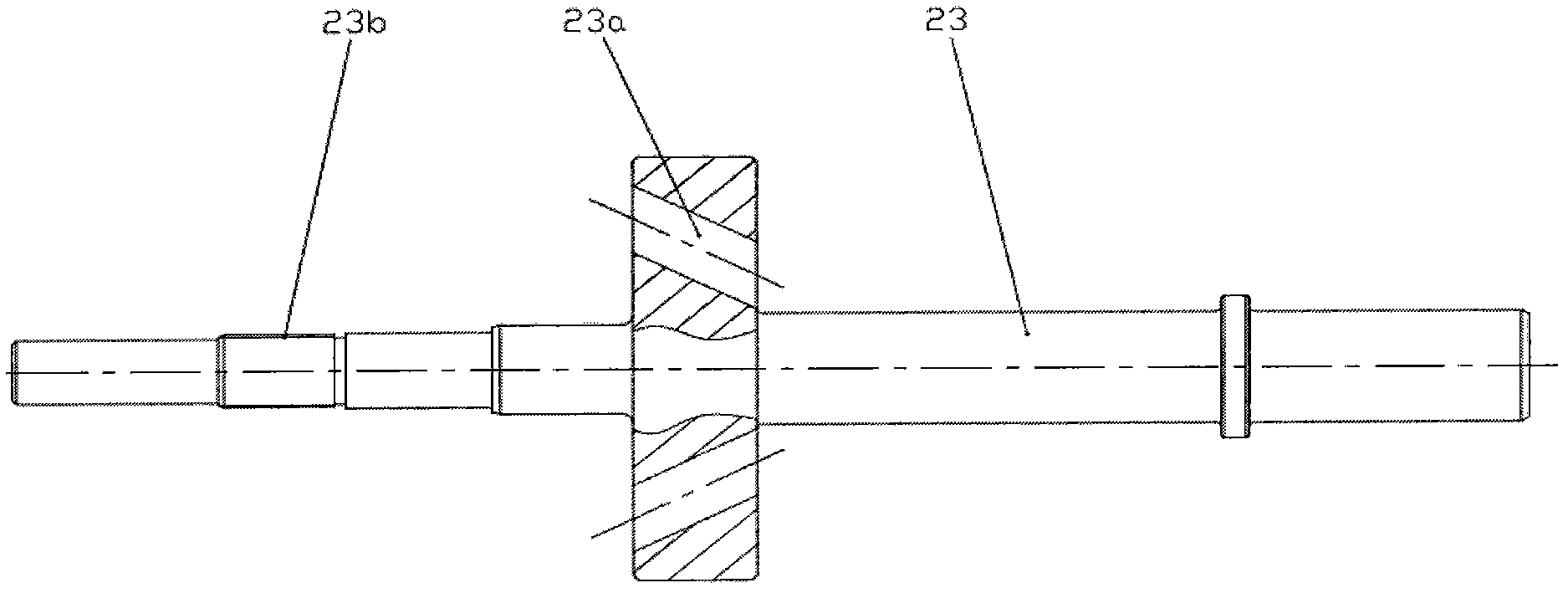

[0009] like Figure 1 to Figure 5 As shown, the present invention is a hydraulic power unit containing a centrifugal pump and a vane pump in a motor, and has a base 1, as well as a motor stator 2, a motor rotor 3, a rotor sleeve 4, a pump core seat 6, and a vane pump 8. The motor rotor 3 and The rotor sleeve 4 and the main shaft 23 are connected to form a rotor body, and are supported on the end cover 20 and the pump core seat 6 through the sliding bearing 15 in the pump core seat 6 and the two sets of rolling bearings 22 in the end cover 20, and the vane pump 8 is splined. 23b is connected to the main shaft 23, the vane pump 8 is installed in the pump core seat 6, and is fixed to the machine through the oil outlet gland 13, the third sealing ring 11, the fourth sealing ring 12, the second screw 9 and the first washer 10. On the base 1, the motor stator 2 is press-fitted on the inner boss 1d on the base 1, the end cover 20 and the fifth sealing ring 19 are fixed on the base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com