Casing-less, long-spiral concrete secant pile construction method

A construction method and concrete technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of easy partial fork and lap joint effect, low construction work efficiency, high construction cost, and ensure construction quality and water-stop effect. , Conducive to civilized construction management and environmental protection, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention is further described.

[0023] A construction method for a long spiral concrete occlusal pile without casing, comprising the following construction steps:

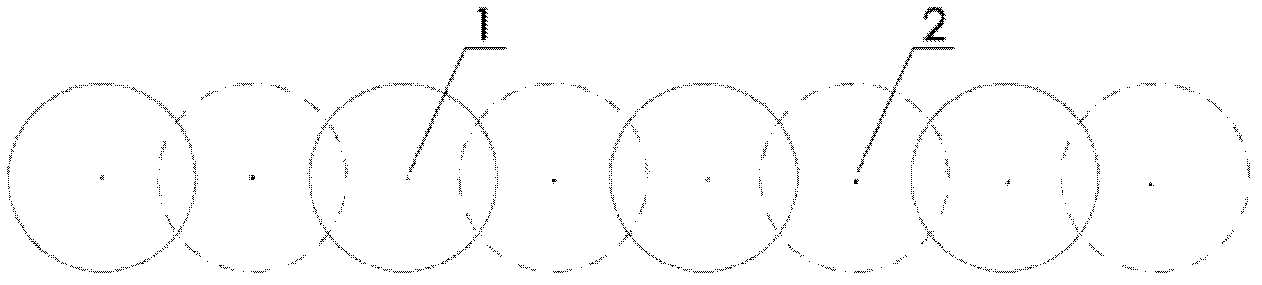

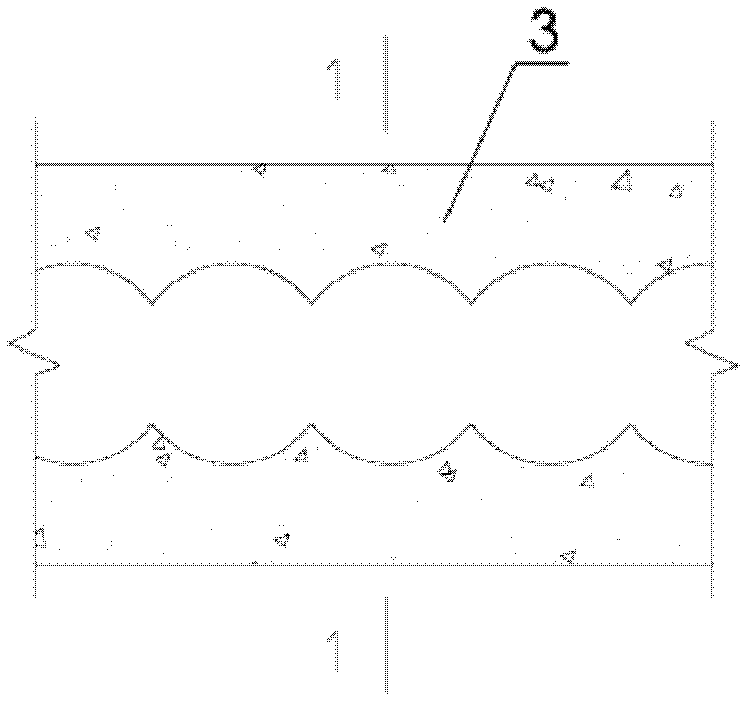

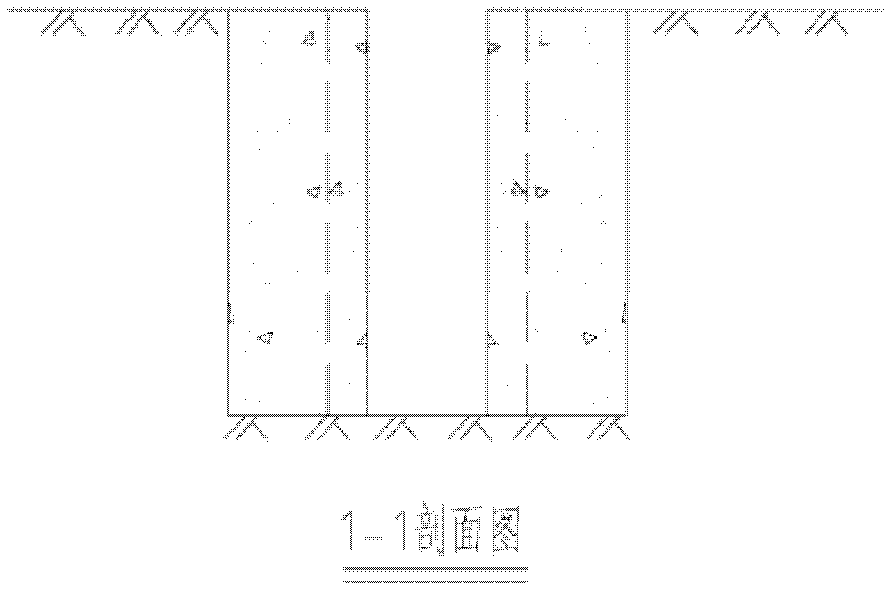

[0024] A. Measure and place the pile position, and the adjacent pile bodies are occluded and overlapped;

[0025] B. The long auger pile driver is in place and centered; when the pile driver travels to the vicinity of the pile position, the chassis of the long auger drill is flat, the tower is vertical and the drill point is aligned with the center point of the pile through adjustment;

[0026] C. Drilling to the design depth;

[0027] D. After drilling to the design depth, lift the drill bit up 0.2m ~ 1m, and then use the concrete delivery pump to transport the concrete to the bottom of the hole through the concrete hose and hollow drill pipe;

[0028] E. After the concrete is poured to the opening of the operation surface, the machine is moved;

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com