Ultra-thinning method of flat liquid crystal TV and flat liquid crystal TV structure

A technology for LCD TVs and flat panels, which is applied to parts of color TVs, parts of TV systems, TVs, etc. It can solve the problems of heat dissipation of parts affecting the life of LCD screens, waste of bases, and inhumanization, so as to improve human nature The effect of modernized design, manufacture, assembly and operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

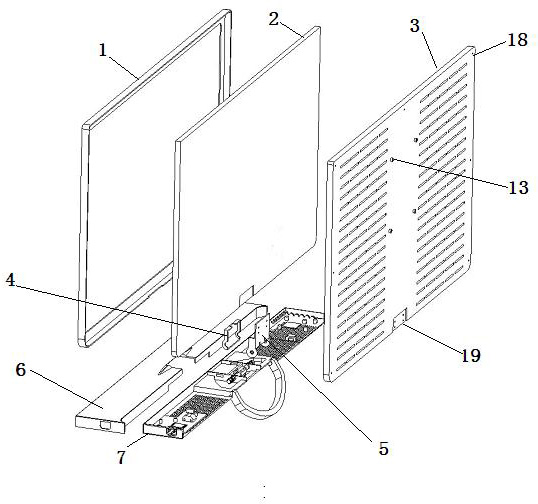

[0034] Such as Figure 3-8 shown.

[0035] A method for ultra-thinning a flat-panel liquid crystal television, comprising the following steps:

[0036] Firstly, install the power supply and the main board in the base, and realize the ultra-thinning of the flat-panel LCD TV by reducing the thickness of the space occupied by the power supply and the main board on the back of the flat-panel LCD TV display; The circuit is connected, and the power supply and the motherboard cooling holes are opened on the base;

[0037] Secondly, a support that can be folded into the gap on the base is provided on the base, and the display screen is installed on the support 5;

[0038] The 3rd, the connection hole 19 ( Image 6 , 8 );

[0039] Fourth, when the flat-panel LCD TV station is installed, the support and the display screen installed on it are perpendicular to the base, such as Figure 5 , 6 As shown; when the wall is installed, the support is inserted into the gap on the base,...

Embodiment 2

[0041] Such as Figure 1-2 , 9, and 10.

[0042] An ultra-thin flat-panel liquid crystal television, which comprises a front shell 1, a liquid crystal screen 2, a rear plate 3, a power supply board 12, a main board 11 and a base 20, and the front shell 1, the liquid crystal screen 2 and the rear plate 3 are assembled into a display screen, The back plate 3 is provided with a wall hanging screw hole 13 and a groove 19 for connecting the support 5 on the base 20, the power board 12 and the main board 11 are installed in the base 20; the support 5 Positioned on the lower housing 7 of the base 20 by the clamping mechanism 8, the support 5 is perpendicular to the base 20 or placed flat on the base 20 in the groove of the clamping mechanism 8, and the power board 12 installed in the base 20 And the main board 11 is electrically connected with the printed display circuit on the liquid crystal screen 2 through the through hole 14 on the support shell 4 of the cover mounted on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com