Adjustable sizing block device

An adjustable and shoring technology, applied to the frame of the engine, supporting machines, mechanical equipment, etc., can solve the problems of inconvenient micro-adjustment, high labor intensity, time-consuming and labor-intensive, etc., and achieve a simple overall structure, reduce labor intensity, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

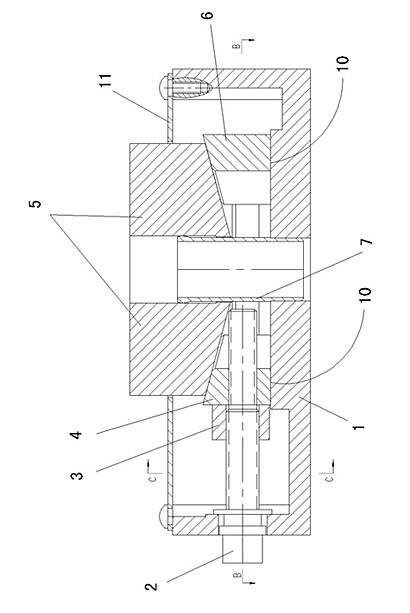

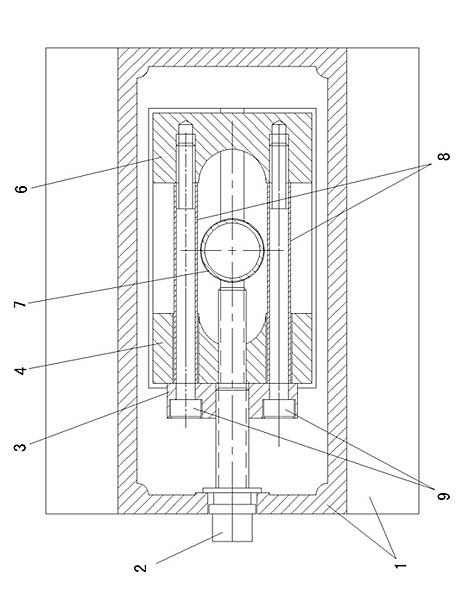

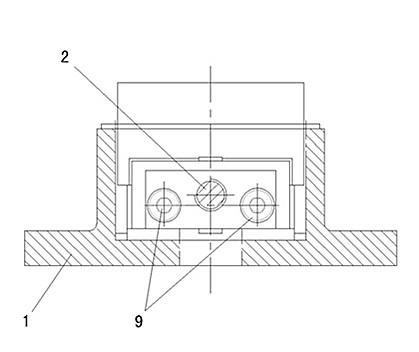

[0011] like figure 1 , 2 , shown in 3: 1 is a trough-shaped seat body, a base surface 10 is processed on the seat body 1, mutually symmetrical left wedges 4 and right wedges 6 are placed on the base surface 10, left wedges 4 and right wedges 6. There is a circular arc notch on the opposite inner side. The tops of the left wedge 4 and the right wedge 6 are inclined planes, and the direction of the inclined planes is inwardly and downwardly inclined. On the slope above the left wedge 4 and the right wedge 6, a support block 5 is arranged, that is, a symmetrical slope is arranged below the support block 5 to coincide with the slope above the left wedge 4 and the right wedge 6.

[0012] A push mechanism is arranged between the left wedge 4 and the right wedge 6, and the structure of the push mechanism is: the left wedge 4 is inserted with a connecting screw 9, and the end of the connecting screw 9 is threadedly connected with the right wedge 6, and the connecting screw 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com