Operation device of shift mechanism in manual transmission

A manual transmission, shifting mechanism technology, applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problems of inability to have load characteristics, difficulty in properly adjusting the shifting feeling, etc., to reduce friction coefficient, reduce The number of parts, the effect of increasing the inclination angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

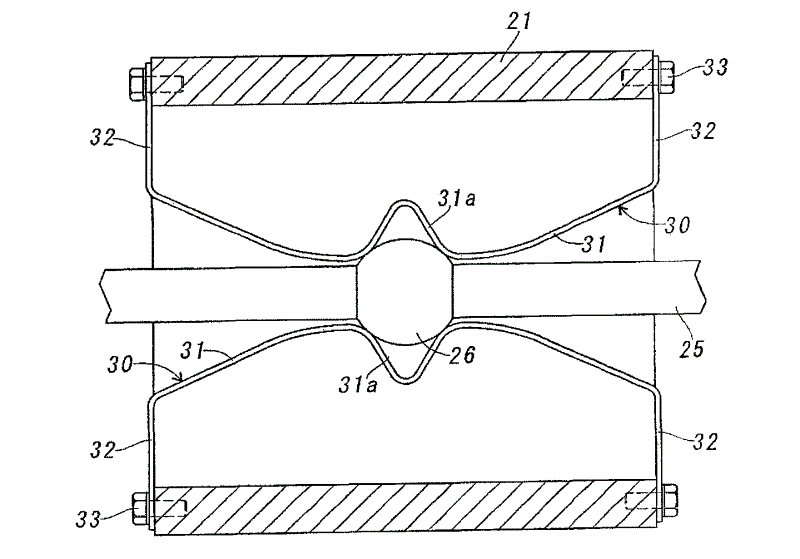

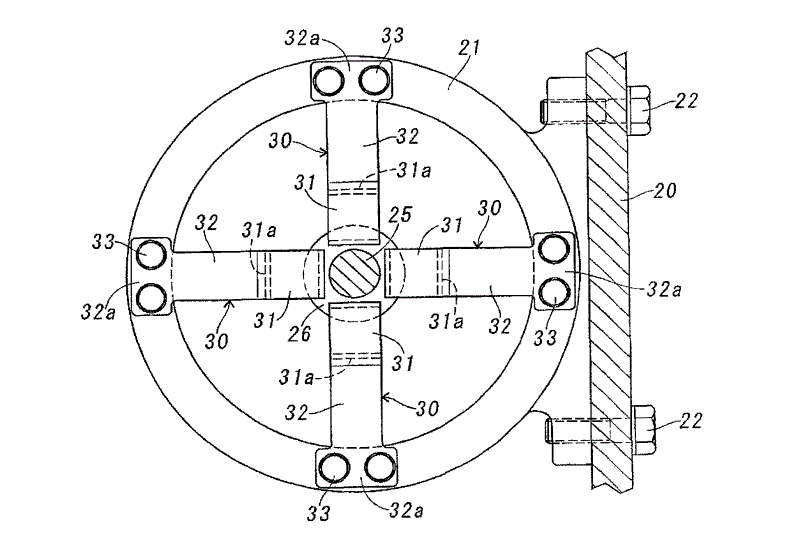

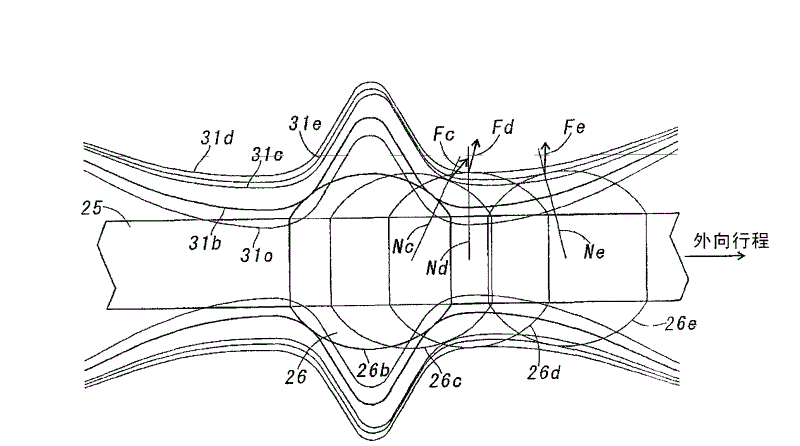

[0026] The present invention is suitable for Figure 8 or Figure 10 An embodiment of the operation shaft of the shift mechanism that moves in the axial direction, such as the fork shaft in the shift and select mechanism shown, will be described below.

[0027] exist figure 1 with figure 2 Among them, the operating shaft 25 is a member provided in the shift mechanism freely movable in the axial direction, and a radially protruding portion 26 having a spherical surface is formed on a part thereof. The cylindrical holding member 21 is fixed inside the transmission case of the transmission, and is fixed concentrically with the operation shaft 25 . The four leaf springs 30 are symmetrically arranged, surround the radially protruding portion 26 of the operation shaft 25 , and are coupled to the spherical surface of the radially protruding portion 26 . Each plate spring 30 is made of metal, and has a V-shaped concave portion 31a in its central portion coupled with the radially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com