Mechanical completion string running tool

A completion string, mechanical technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of wasting time, difficult to rotate the string, and construction requirements are not allowed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Taking an upper casing 1 as 95 / 8" upper casing, completion string 2 as 51 / 2" and a mechanical completion string running tool connected at the lower end of completion string 2 as an example , the present invention will be described in further detail.

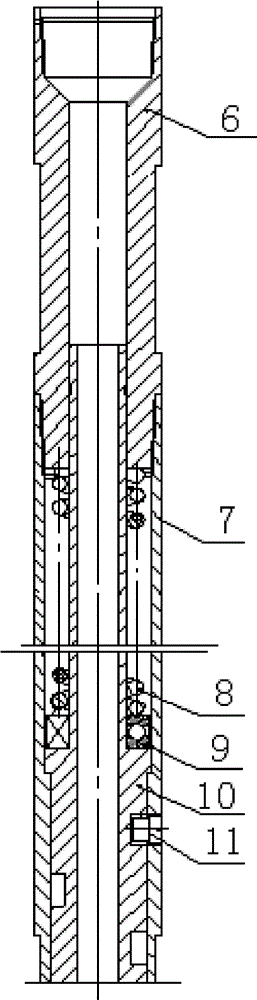

[0016] refer to figure 1 and figure 2 . The mechanical completion string running tool mainly consists of an upper joint 6, a guide sleeve 7, a compression spring 8, a plane bearing 9, a rotating mandrel 10, a guide pin 11, a protective sleeve 12, a transition short 13 and a cutting tooth Casing shoe 14 consists of.

[0017] The upper end of the upper joint 6 has an API standard casing internal thread, which can be connected to the lower end of the completion string 2 . The length of the upper joint 6 is 650mm, and the outer diameter is 154mm, and the diameter of the central hole of the upper joint 6 is 70mm. The lower end of the upper joint 6 has an external thread, and the lower end of the upper joint 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com