Large-span continuous steel truss girder arch pushing device

A steel truss girder and large-span technology, which is applied in the field of large-span continuous steel truss girder with vault push device, can solve the problems of reducing construction efficiency, affecting the overall stability of steel truss girder, and failing to meet the requirements of the designed bridge, so as to achieve saving Cost, effect of simplifying construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

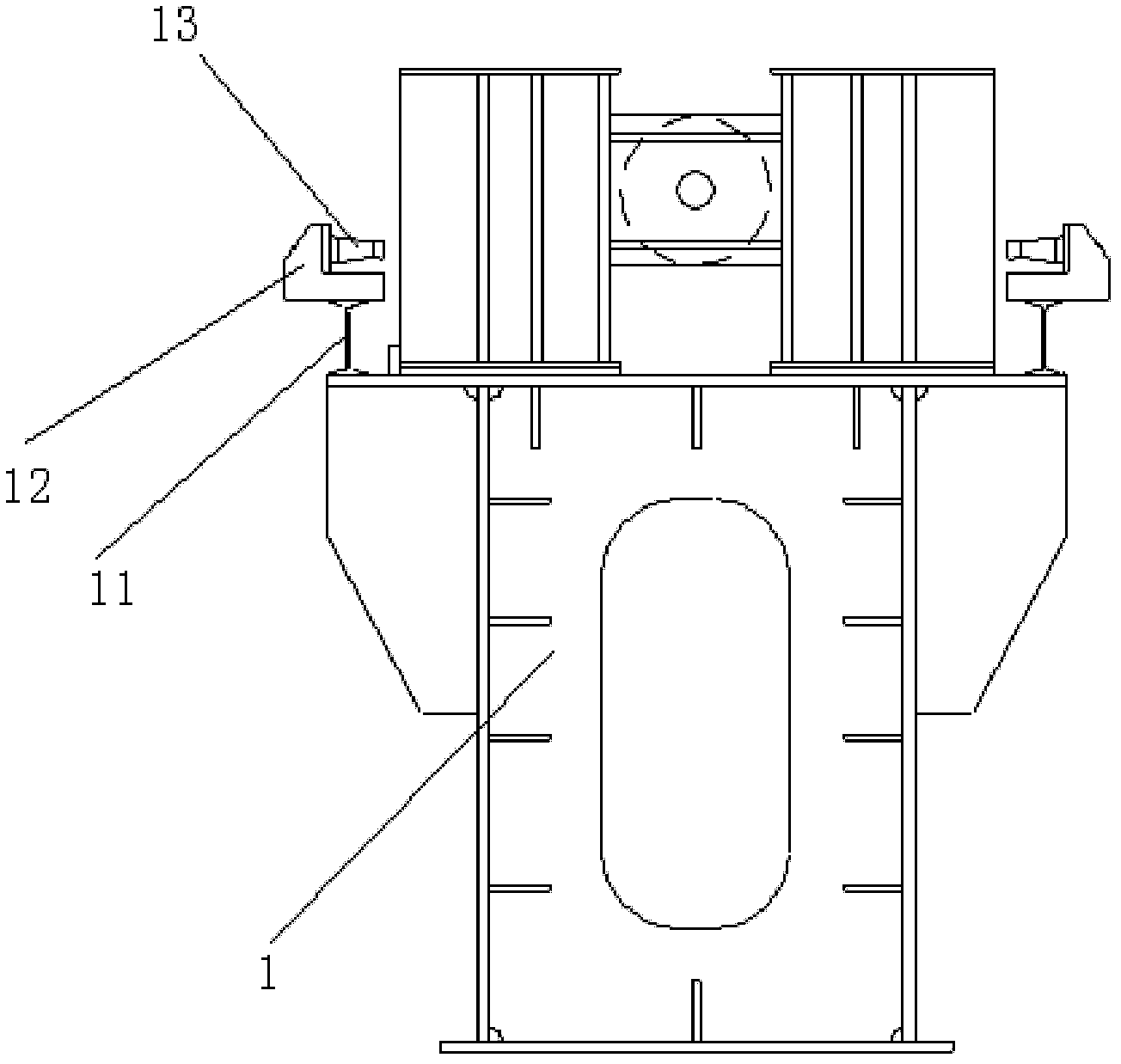

[0026] Referring to the accompanying drawings, a large-span continuous steel truss girder belt vault push device includes a sliding device and a main pushing system device. The sliding device includes left and right longitudinal slideway beams 1, 2, and a slider 3. The inner edges of the left and right longitudinal slideway beams 1 and 2 are respectively provided with longitudinal full-length limit stops 4, and the inner wall of the slider 3 is placed on the longitudinal full-length limit stop 4, and the left and right longitudinal The top surface of the slideway beam is laid with a longitudinal stainless steel main slideway, and the ends of the left and right longitudinal slideway beams are provided with a lifting protection pier 5, the lifting protection pier 5 is less than the height of the slider 3, and the outside of the slider is provided with The deviation correction device is divided into tracking deviation correction device and fixed deviation correction device. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com