Longitudinal rotary transformer screw propeller

A propeller, longitudinal rotation technology, applied in the directions of rotating propellers, propellers, rotary propellers, etc., can solve the problems of reduced maneuverability and load capacity, limited number of rotor blades, and poor maneuverability of military models, and achieves increased maneuverability. The effect of performance, strong competitiveness, and strong maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

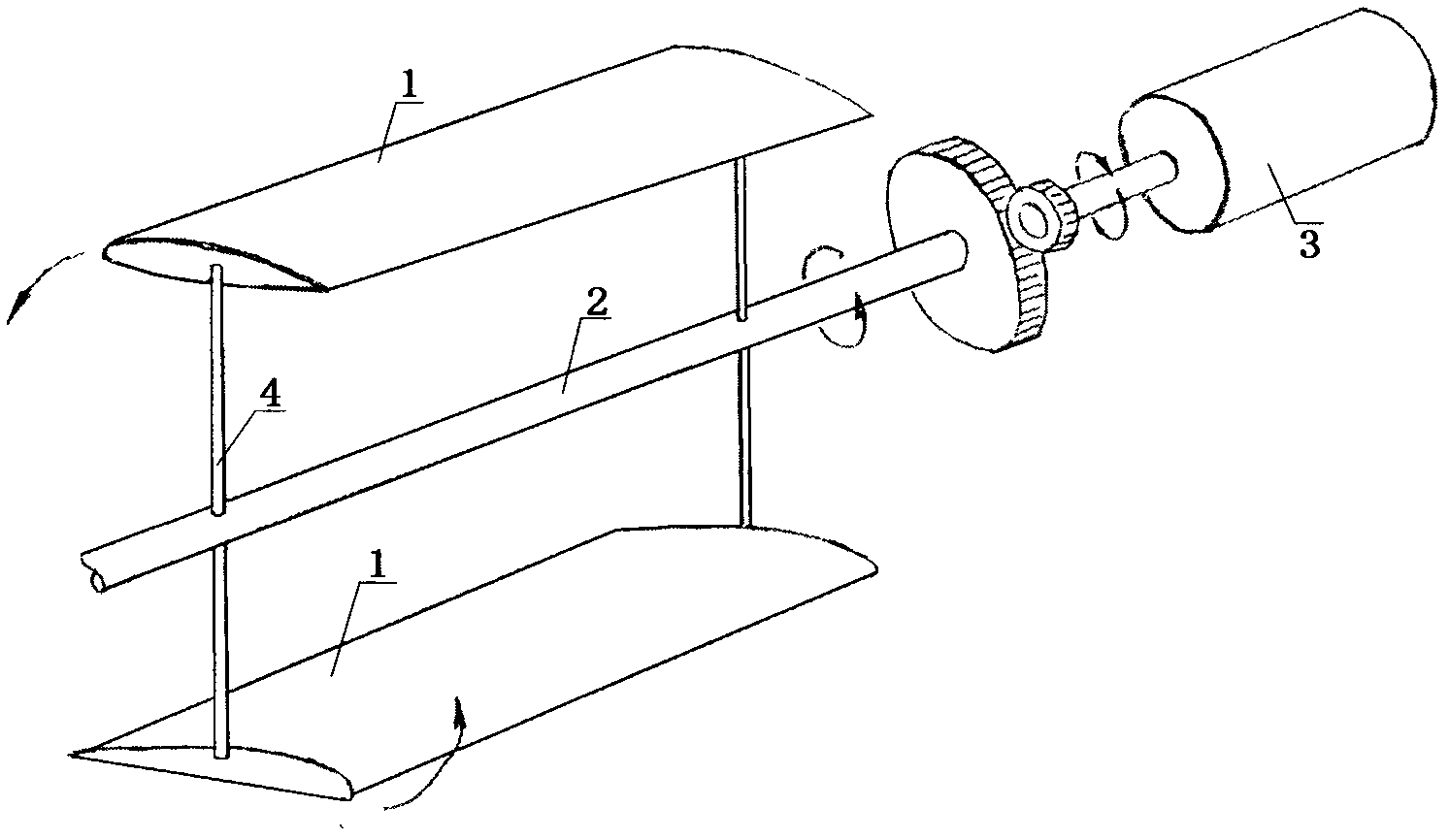

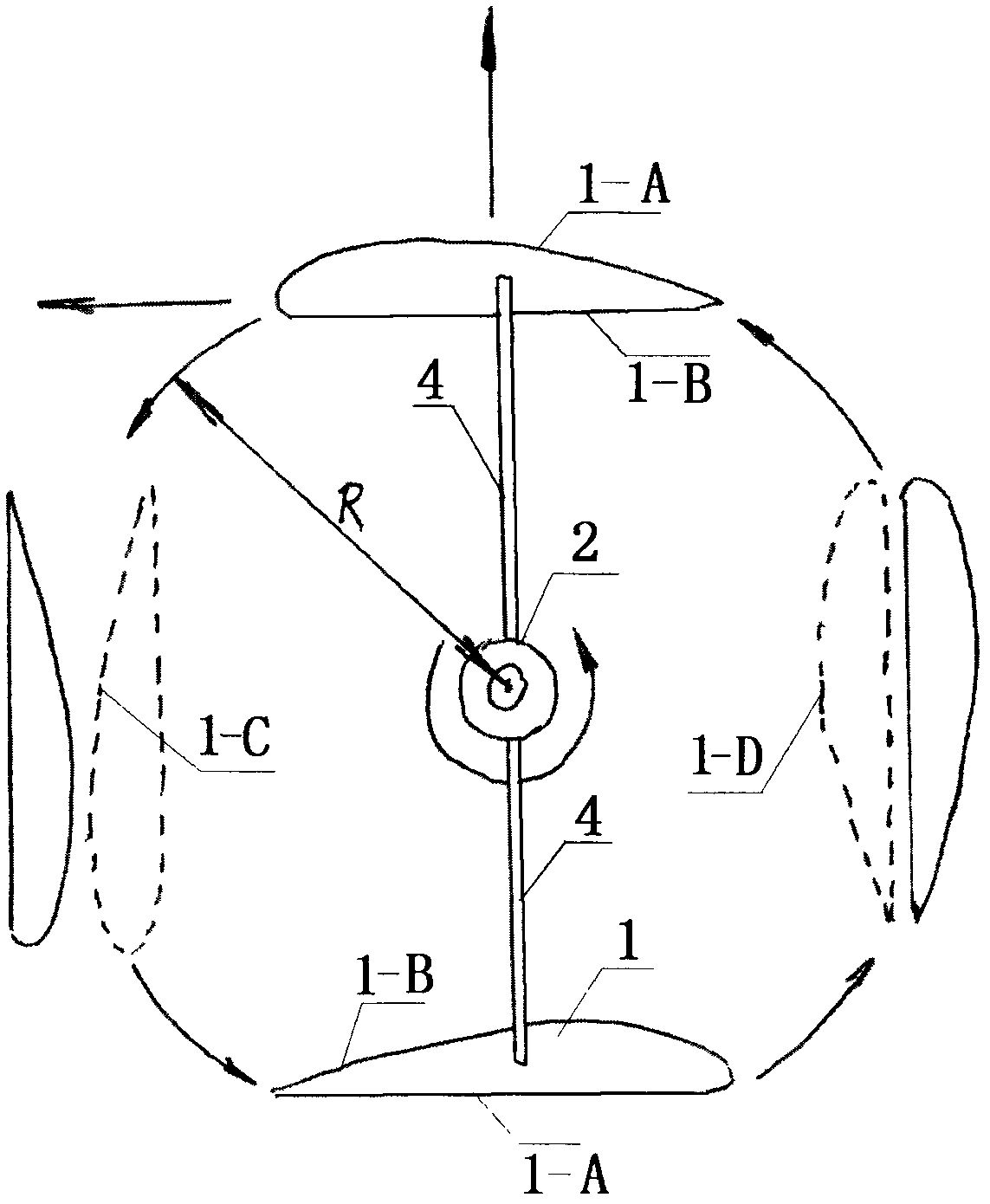

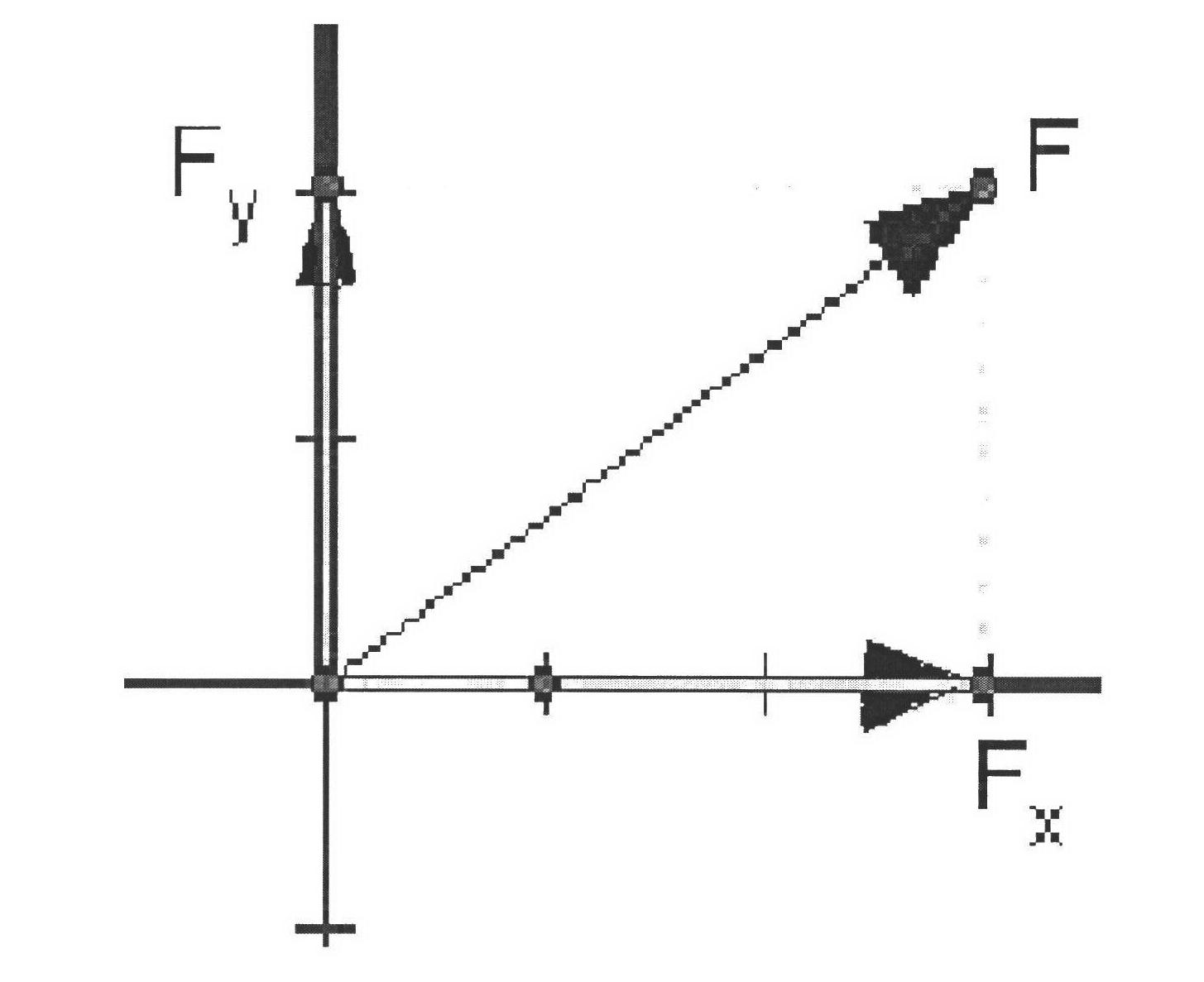

Method used

Image

Examples

Embodiment 1

[0211] aircraft:

[0212] Aircraft that move in the atmosphere include balloons that are lighter than air, such as airships, and rockets that do not require air as an oxidant, but mainly refer to aircraft. From the perspective of wings, aircraft are divided into three categories: fixed-wing aircraft, helicopters, and rotorcraft.

[0213] The rotorcraft utilizes the relative air flow when flying forward to blow the rotor to rotate to generate lift. It is a kind of aircraft between the fixed-wing aircraft and the helicopter. Its rotor is actually a propeller without power, and there is nothing unique in theory. Although the gyroplane has some advantages, so it has not disappeared at present, but its disadvantages are more fatal, so it is still not a climate. Its speed is slow, the range is short, and it cannot avoid nearby obstacles; although it is very similar to a helicopter, it can neither take off vertically nor hover, and its maneuverability is very poor; compared with fl...

Embodiment 2

[0261] car:

[0262] The main advantage of the present invention in the automobile field should be in " all-terrain vehicle " aspect.

[0263] The so-called all-terrain vehicle is defined as "a vehicle suitable for all terrains" (English All Terrain Vehicle, abbreviated ATV).

[0264] At present, the mainstream driving mode of automobiles is wheel drive. This is also the only mainstream driving method for automobiles. Other driving methods such as track drive, jet drive, etc. cannot and cannot replace the dominance of wheel drive.

[0265] The principle of wheel drive is that the tires exert force on the ground, and the ground exerts a reaction force on the tires. This reaction force is the real force driving the car.

[0266] Every car wants this counterforce to be strong enough. To make the reaction force strong enough, the action force must first be strong enough. But for all-terrain vehicles, this problem is not the most important. Otherwise, wouldn't any high-powered...

Embodiment 3

[0282] ship:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com