Sewage diversion trench suction filter system

A diversion tank, sewage technology, applied in the direction of filtration and separation, moving filter element filter, separation method, etc., can solve the problems of difficult biochemical degradation, increase COD chemical oxygen demand, increase the volume of functional pools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

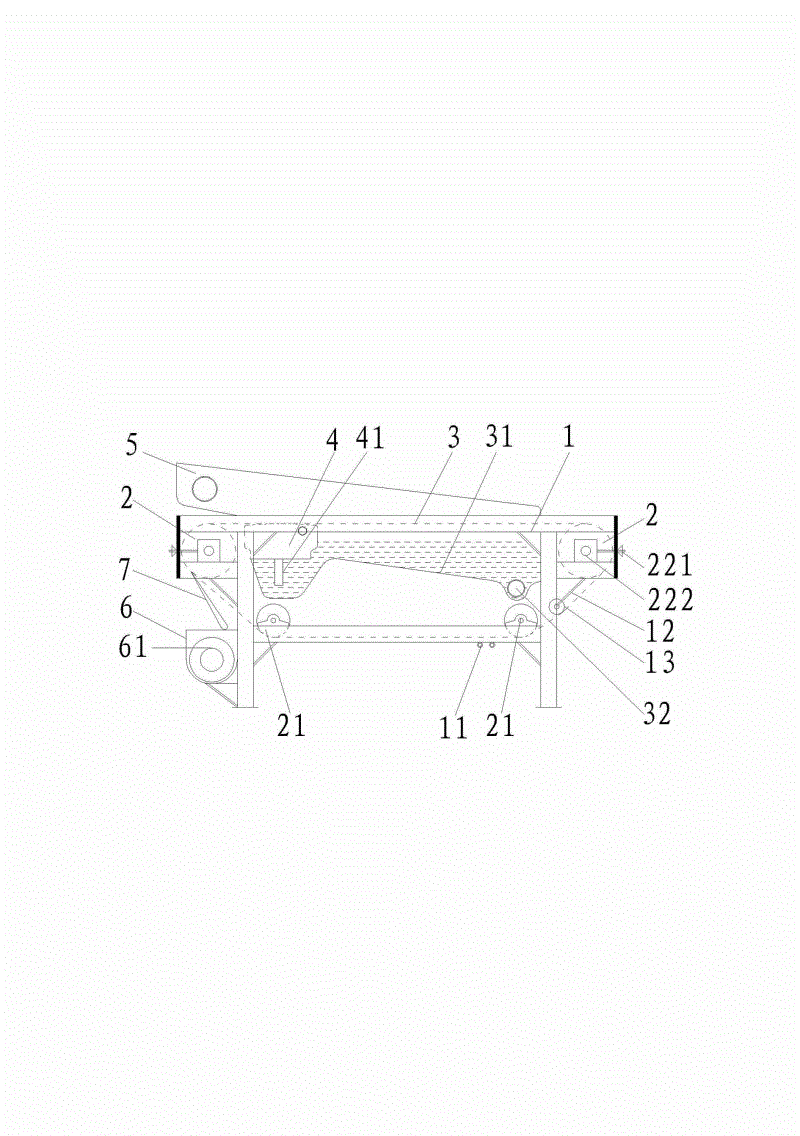

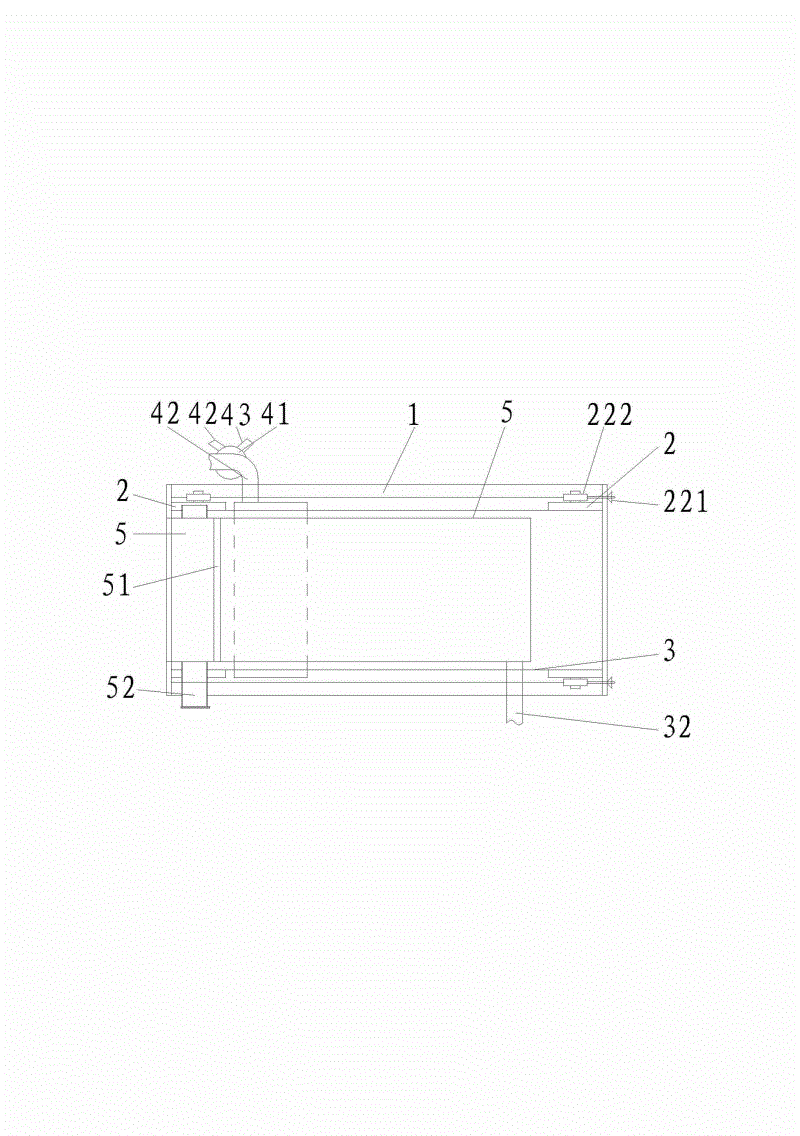

[0013] Such as figure 1 , figure 2 As shown, the sewage diversion tank suction filtration system includes a bracket 1, two main rollers 2 arranged at both ends of the bracket 1, a filter cloth belt 3 set on the two main rollers 2, and a filter cloth belt 3 arranged between the two main rollers 2 The sump 31 , the vacuum box 4 arranged on one side of the sump 31 , the water inlet 5 arranged above the sump 31 , and the two main rollers 2 are driven by motors. When in use, the sewage is collected in the sump, the sewage enters the water inlet tank 5 through the water inlet pipe 52, and then enters the overflow tank 51 from the water inlet tank 5, and then the overflow tank 51 overflows on the filter cloth belt 3, and the filter cloth belt 3 The moisture content on the surface is sucked in a large amount in the vacuum box 4 when passing through the vacuum box 4, enters the water collection tank 31 through the water seal pipe, or enters in the water collection tank 41 through the...

Embodiment 2

[0015] Such as figure 1 , figure 2 As shown, a spiral mud outlet 6 is provided under the main roller 2 and the filter cloth belt 3, and a mud scraper 7 is arranged directly above the spiral mud outlet 6, and the mud scraper 7 is used to scrape off the filter cloth. With the sludge on the outside of the belt 3, a screw shaft 61 is arranged in the screw mud discharge tank 6, and the screw shaft 61 is driven by a motor.

Embodiment 3

[0017] Such as figure 1 , figure 2 As shown, the water inlet tank 5 is provided with an overflow tank 51, and the support below the two main rollers 2 is provided with two auxiliary rollers 21 to change the direction of movement of the filter cloth belt 3. The two main rollers 2 are provided with There is a tension adjustment mechanism, the tension adjustment mechanism 22 is composed of a movable seat 222 installed at both ends of the main roller 2 and an adjustment screw 221. The adjustment bolt 221 is installed on the bracket 1, and the inner end of the adjustment bolt 221 is fixed on the movable On the seat 222, the movable seat 222 can be adjusted left and right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com