Processing device for superfine tea powder

A processing device and ultra-fine tea powder technology, which is applied in tea treatment before extraction, etc., can solve the problem that the product cannot be graded, and achieve the effects of narrow product particle size distribution, long service life of equipment, and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

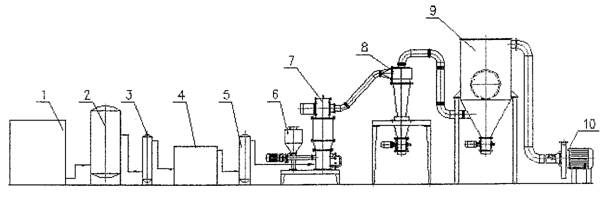

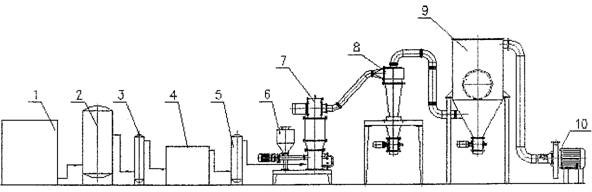

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 The processing device for superfine tea powder shown, the device includes compressed air power source and oil-water separator 1, gas storage tank 2, primary filter 3, gas dryer 4, precision filter and sterilizing filter 5, material The warehouse 6, the fluidized bed airflow pulverizer 7, the cyclone collector 8, the bag collector 9 and the high-pressure induced draft fan 10, the compressed air power source and the oil-water separator 1 are connected to the air storage tank 2 through the air path, and the storage The gas tank 2 is connected to the primary filter 3 through a gas path, the primary filter 3 is connected to the gas dryer 4 through a gas path, and the gas dryer 4 is connected to the precision filter and the dehumidifier through a gas path. The bacteria filter 5, the precision filter and the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com