Auto-tune of a control system based on frequency response

一种控制系统、控制器的技术,应用在方法和系统领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

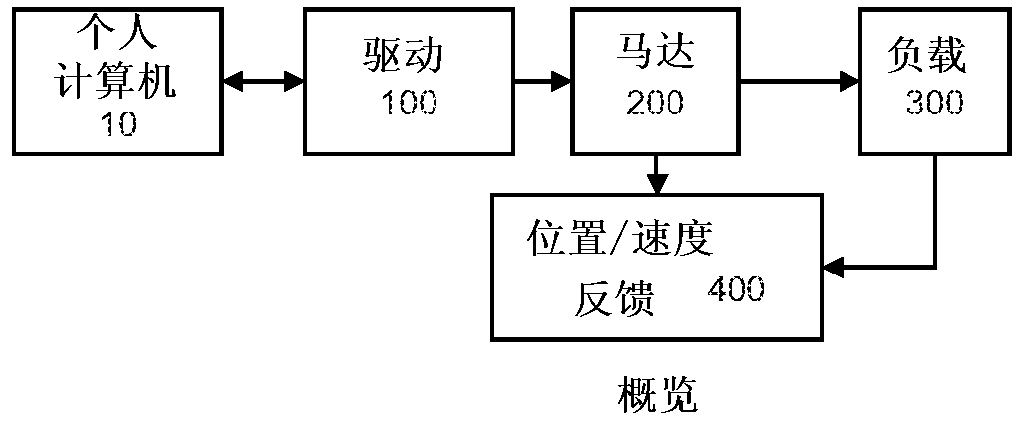

[0037] figure 1 Illustrates an overview of a motor control system in which an auto-tuning system is implemented. The motor control system includes a drive 100 , a motor 200 , a driven load 300 and a position and / or speed measurement device 400 . It should be understood that there are many variations of feedback structures, including a single position sensor on the motor, a single position sensor on the load, a combination of a position sensor on the motor and another position sensor on the load, all of which are included herein . It should be understood that the velocity may be measured directly on the motor, load, or both, rather than being calculated from a position sensor. This configuration is also included here. It should be understood that position and velocity may be calculated using "sensorless" techniques that use the characteristics of the motor to sense position and velocity. This configuration is also included here.

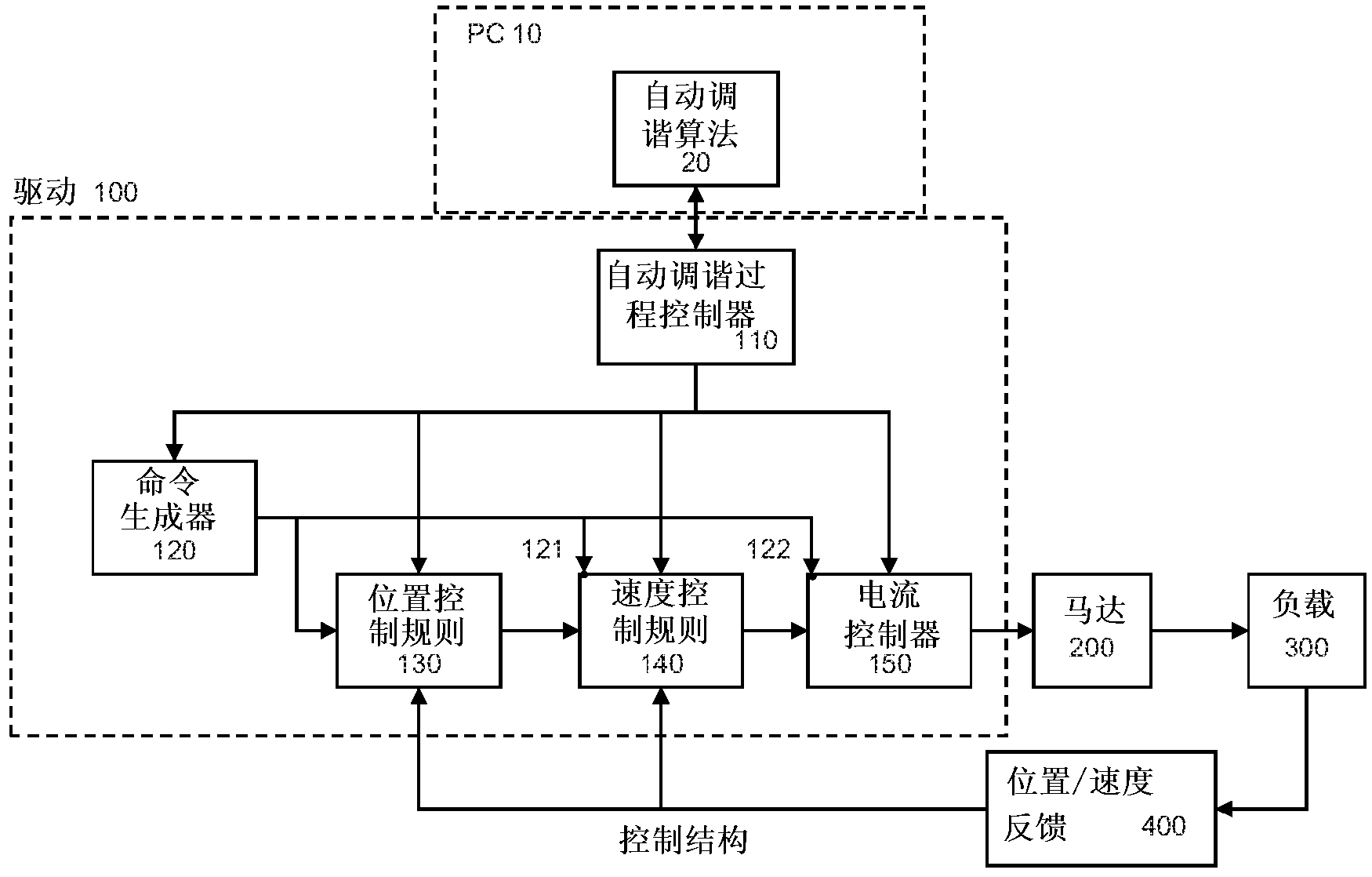

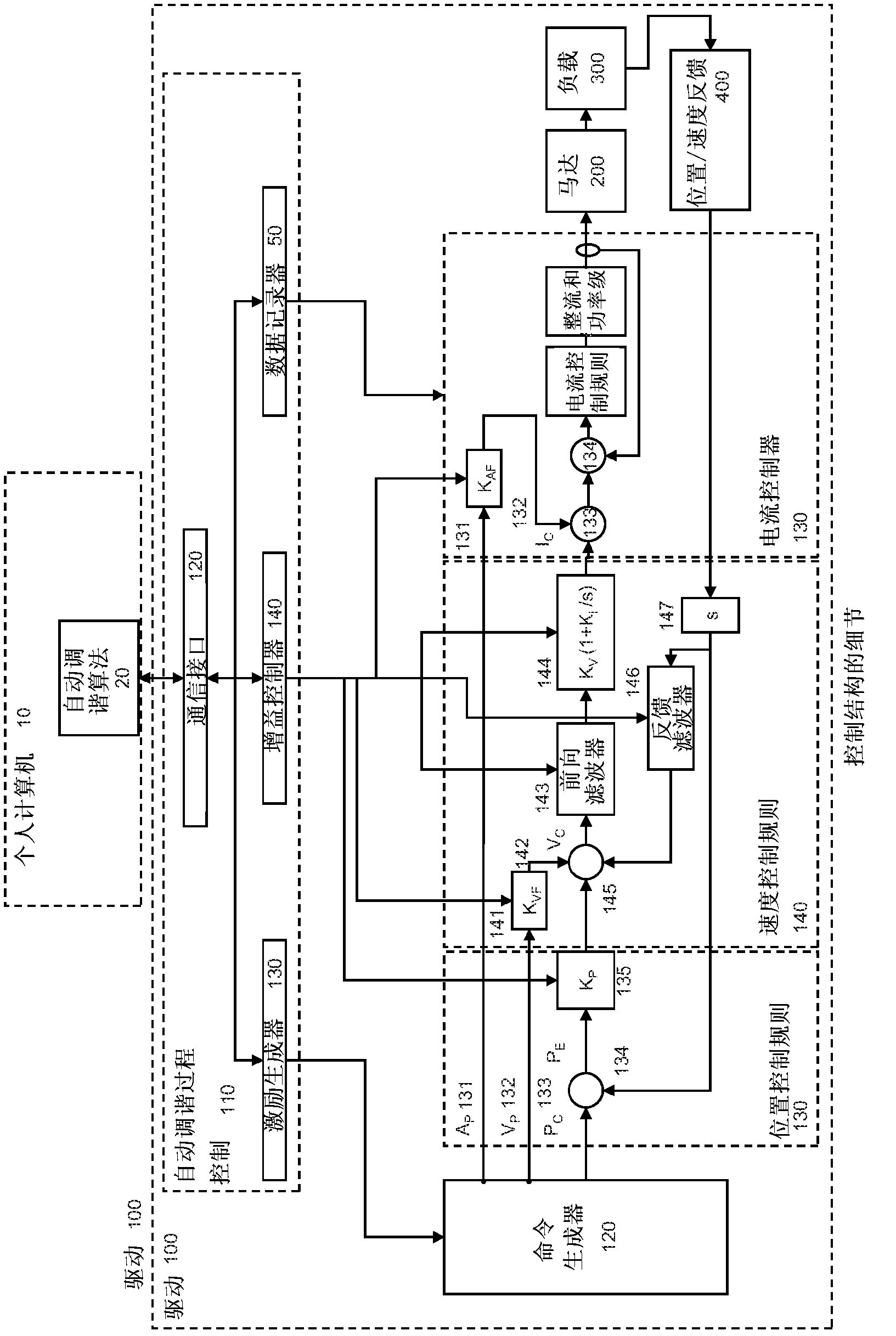

[0038] figure 2 A view showing a control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com