Signal line fixing structure of resolver

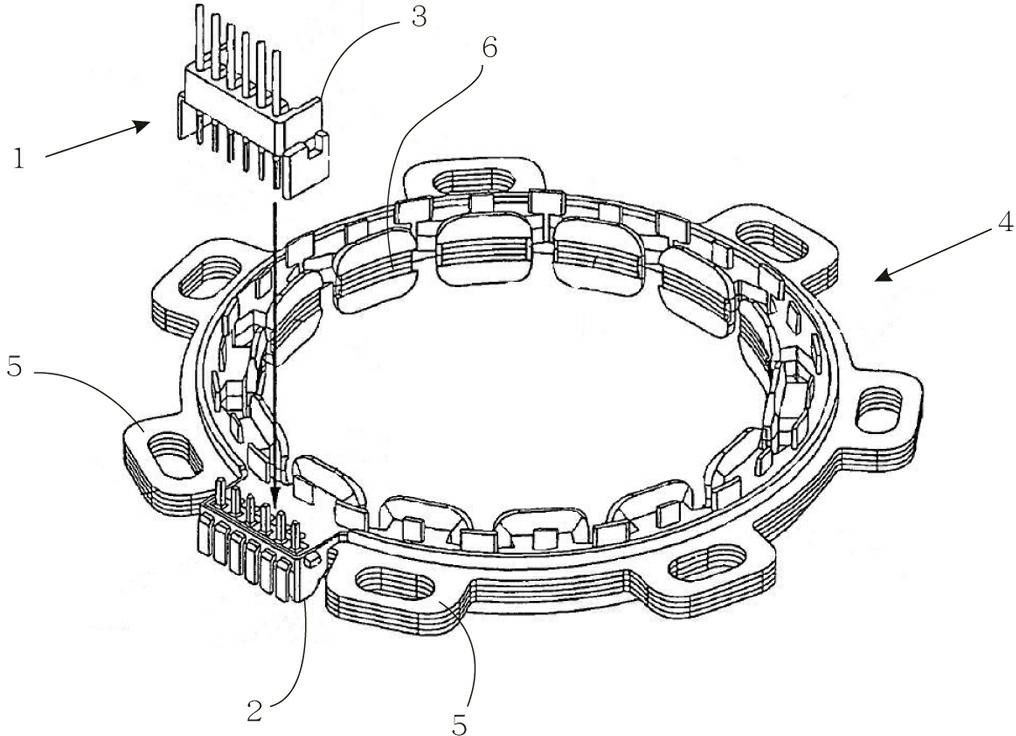

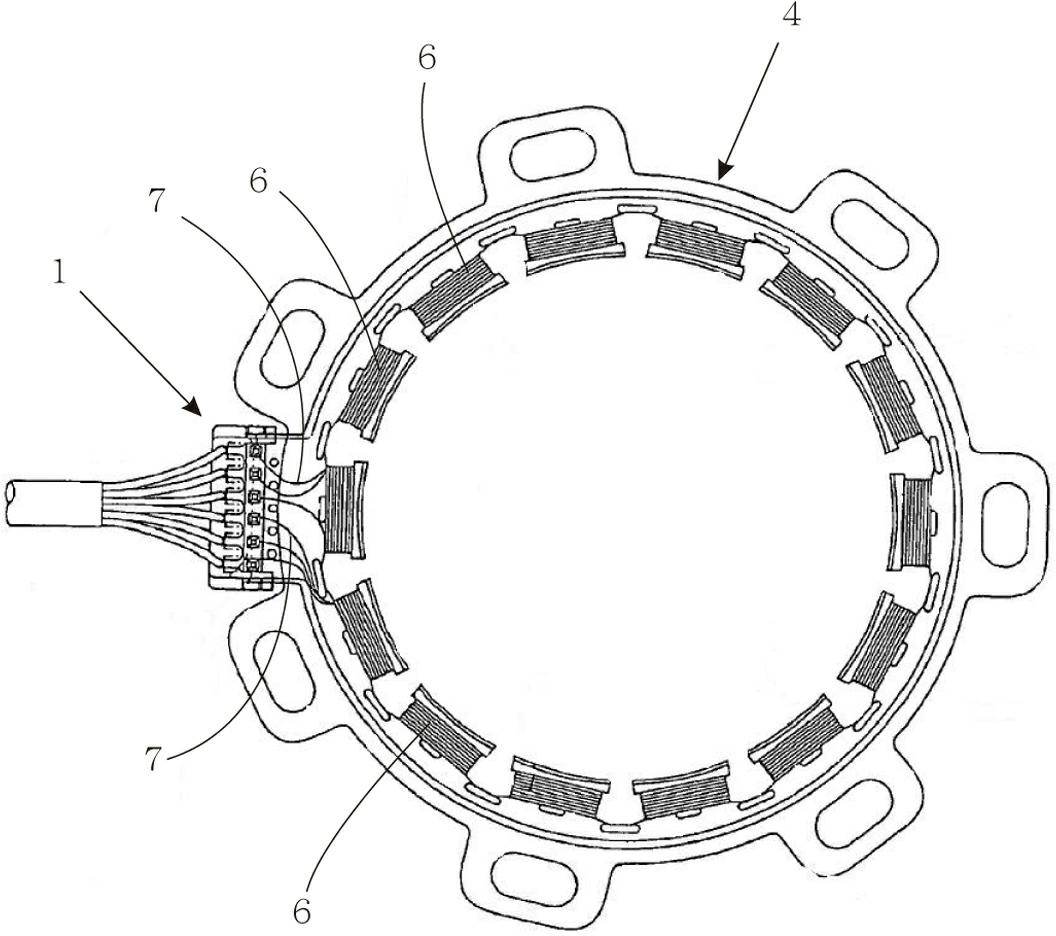

A technology of resolver and signal line, applied in the field of resolver, can solve the problems of damage, lengthy process requirements of the whole line procedure, and falling off of the extension lead 7, so as to reduce the demand of the whole line, ensure the reliability, and shorten the length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

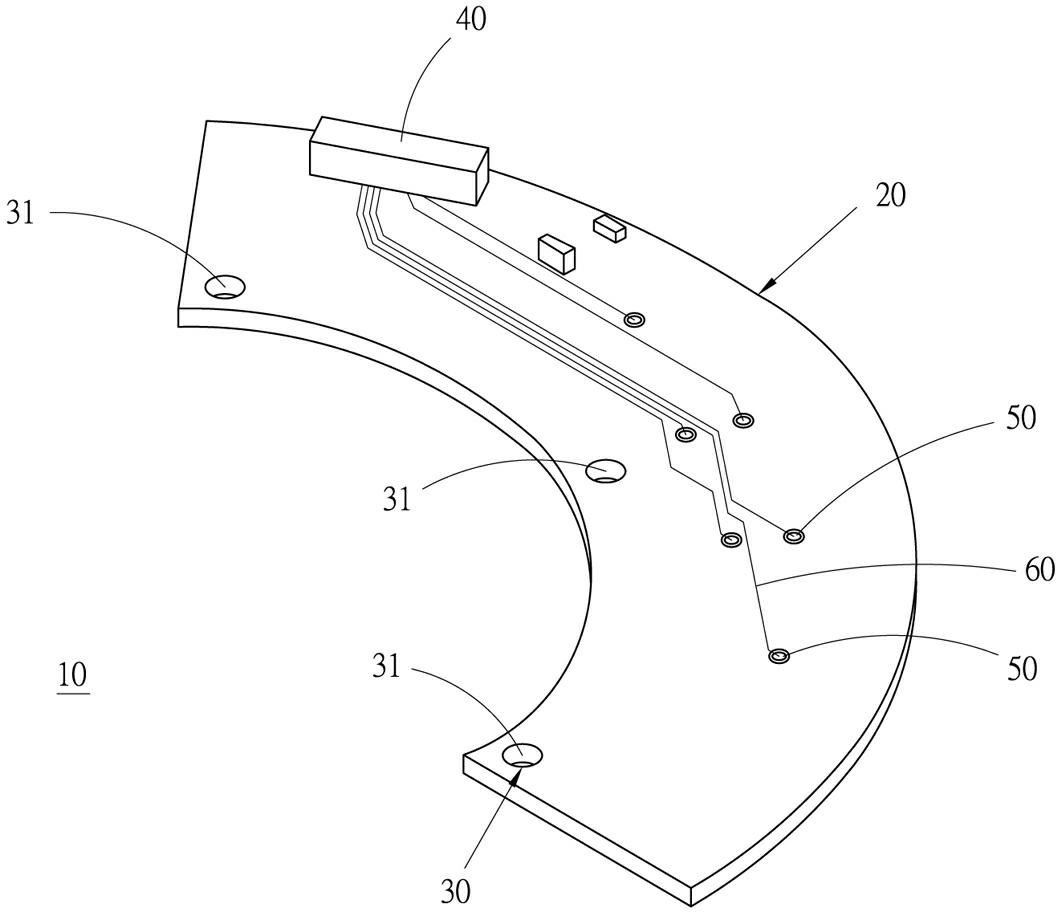

[0038] see Figure 3 to Figure 6 As shown, the signal line fixing structure 10 of the resolver provided in a preferred embodiment of the present invention is mainly composed of a circuit board 20, a fixing part 30, a combined terminal block 40, a plurality of connecting parts 50 and It is composed of a plurality of bridge circuits 60 .

[0039] The circuit board 20 is roughly in the shape of an arc plate, and is attached to the axial end surface 71 of a resolver stator 70 with one side plate surface 21, and its center of curvature corresponds to the axial coaxial direction of the stator 70, and The size of the circuit board 20 covers a plurality of coils 72 with winding ends on the stator 70 , so that each winding end is located within the projected range of one side of the circuit board 20 .

[0040] The fixing part 30 is used to combine the circuit board 20 on the axial end surface 71 of the stator, and has three fixing holes 31 respectively penetrated between the two side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com