Lithium ion battery

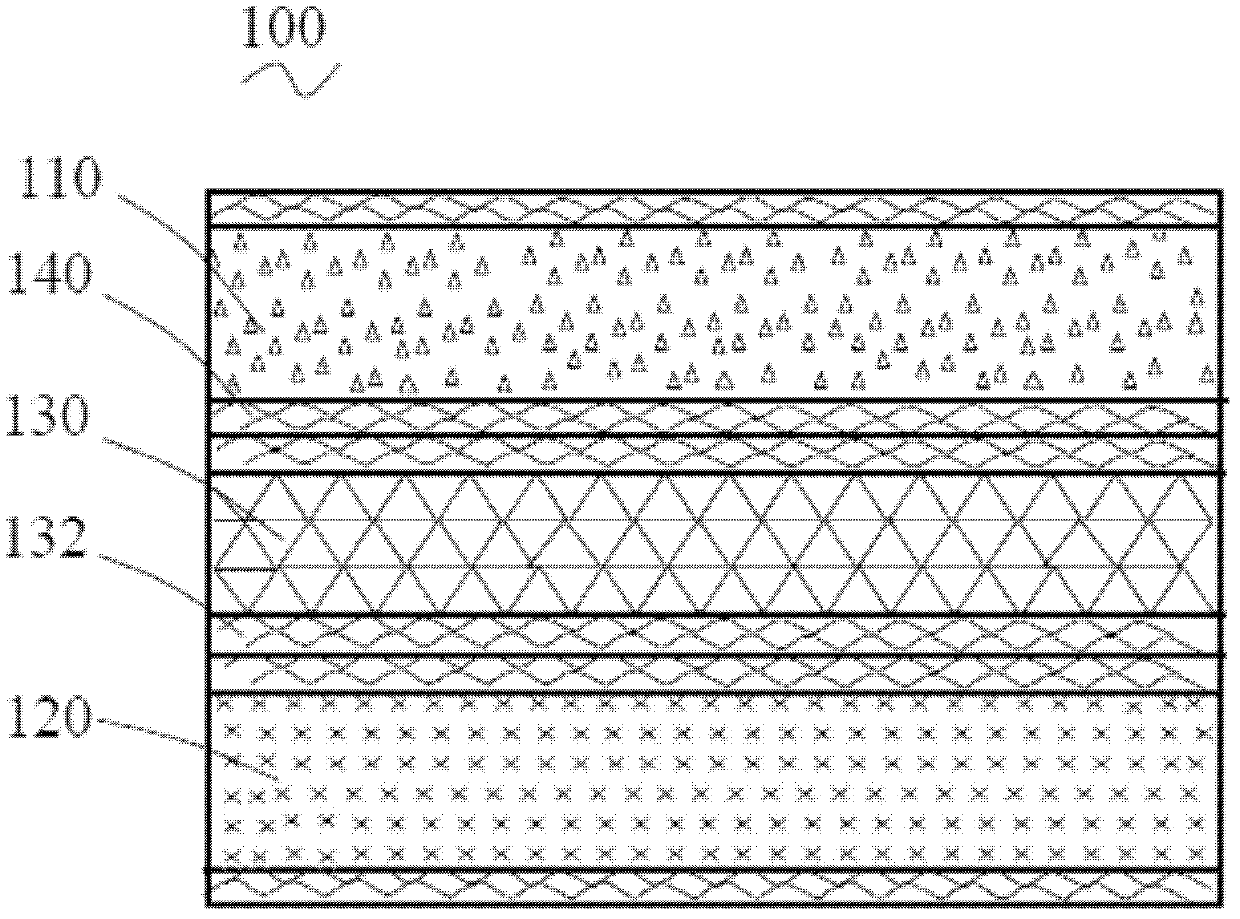

A lithium ion battery, ion conduction technology, applied in secondary batteries, battery electrodes, battery pack components and other directions, can solve the problem of electrode composite material curvature limitation, inability to obtain high areal density electrode composite materials, electrode peeling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, its processing step is as follows:

[0039] Step 1: 7 grams of polymer polyvinylidene fluoride was added to 180 grams of N-methylpyrrolidone (NMP), which was thoroughly stirred to dissolve to form a colloidal solution.

[0040] Step 2: The production procedure of the positive electrode composite material is as follows: 7 grams of polyvinylidene fluoride, a binder, is added to 180 grams of N-methylpyrrolidone (NMP) to be fully stirred and dissolved to form a colloidal solution, and 140 grams of polyvinylidene fluoride is added to the solution. g LiFePO 4 Fully mixed with 2.8 grams of conductive carbon Super-P and added to the above colloidal liquid, and stirred with a mixer to make a paste-like positive electrode slurry. The obtained positive electrode material slurry was filled onto the current collector from both sides of 90% porous aluminum foam by the doctoring method. The above current collector containing the electrode slurry was placed in a 110° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com