Abrasion in-situ measuring device based on digital image processing and method

A measuring device and digital microscope technology, applied in the direction of testing wear resistance, etc., can solve the problems of complicated operation, limited accurate measurement, and inability to give wear surface characteristics, etc., and achieve the effect of accurate analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] best practice

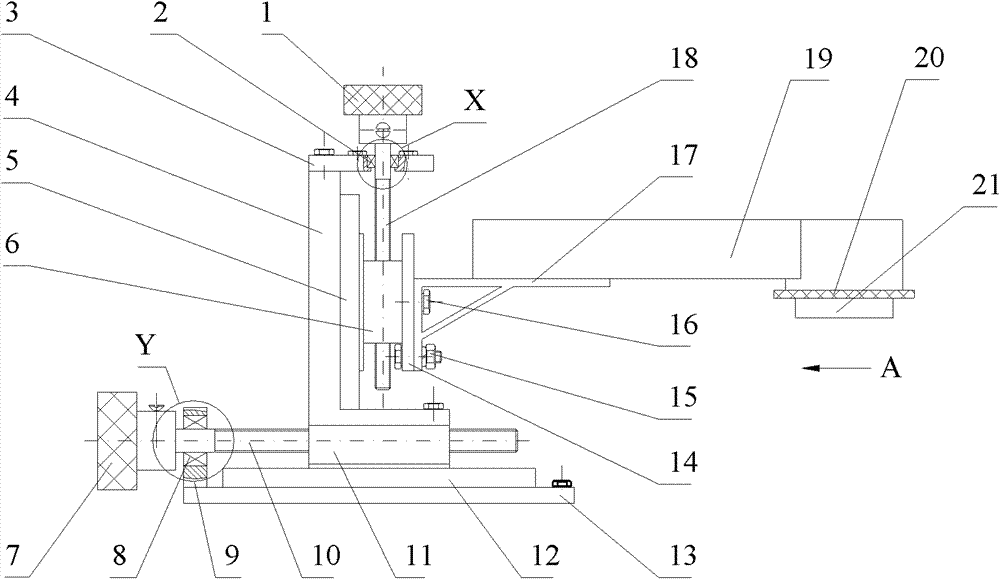

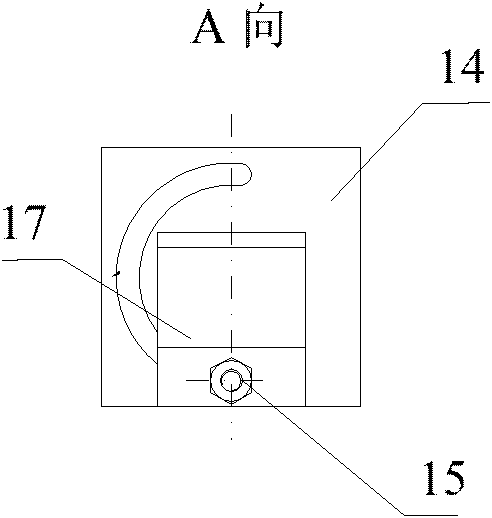

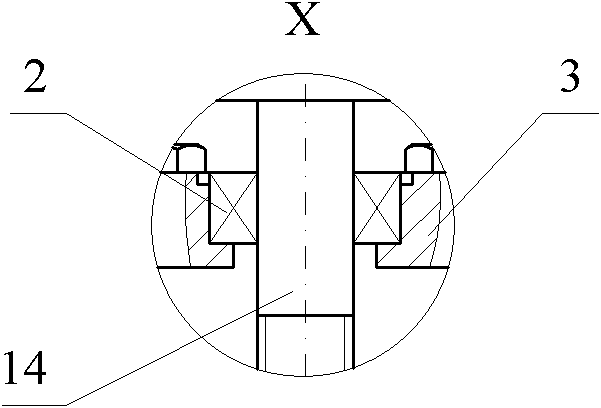

[0037] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] Such as figure 1 As shown, in the in-situ measurement device for wear and tear, the base plate 13 is fixed on the test bench, the large linear guide rail 12 and the bearing seat 9 are arranged on the base plate 13, and the large screw nut 11 is arranged on the large linear guide rail 12 to connect the large linear guide rail 12. Leading screw 10, bearing seat 9 is provided with embedded bearing 8 in order to support large leading screw 10, and large leading screw 10 left end connects large knob 7, the rotation of convenient large leading screw 10 realizes the horizontal movement of device. The big lead screw nut 11 is provided with a pillar 4, the right side of the pillar 4 is provided with a small linear guide 5, and the upper side of the pillar 4 is provided with a top plate 3. The right side of the small linear guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com