Method and device for measuring surface shape error of optical element at high precision

A technology of optical components and surface shape error, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of cumbersome calibration of interferometers, high prices, and high requirements for the test environment, and achieve simple, fast and cost-effective testing and calibration processes. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

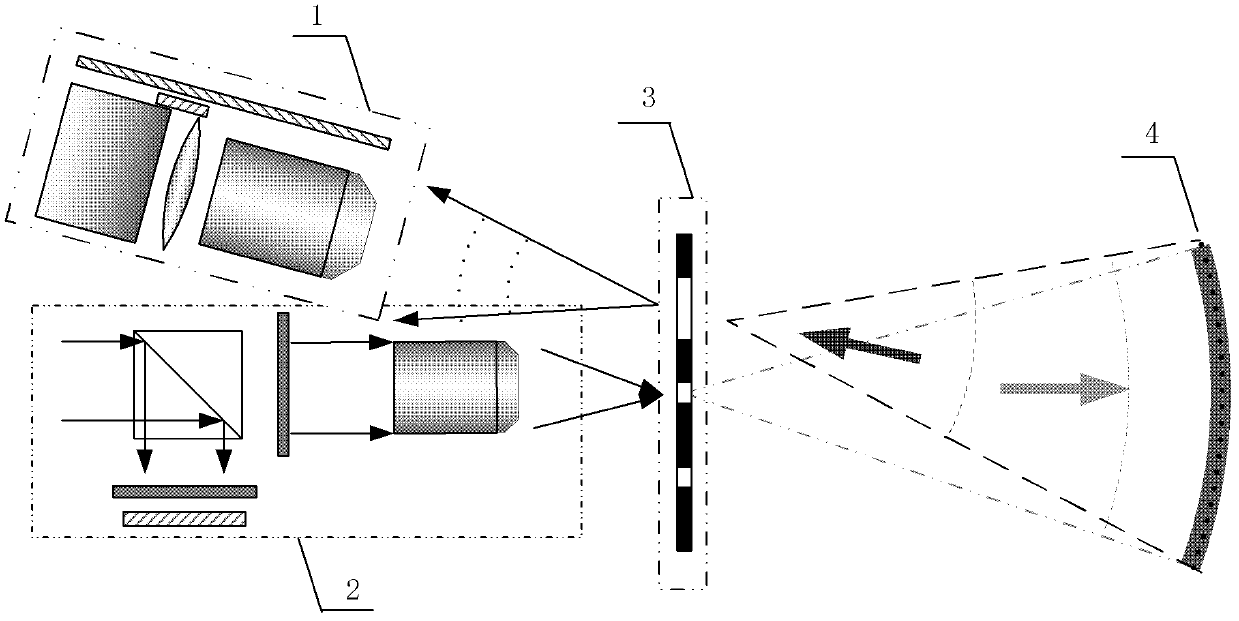

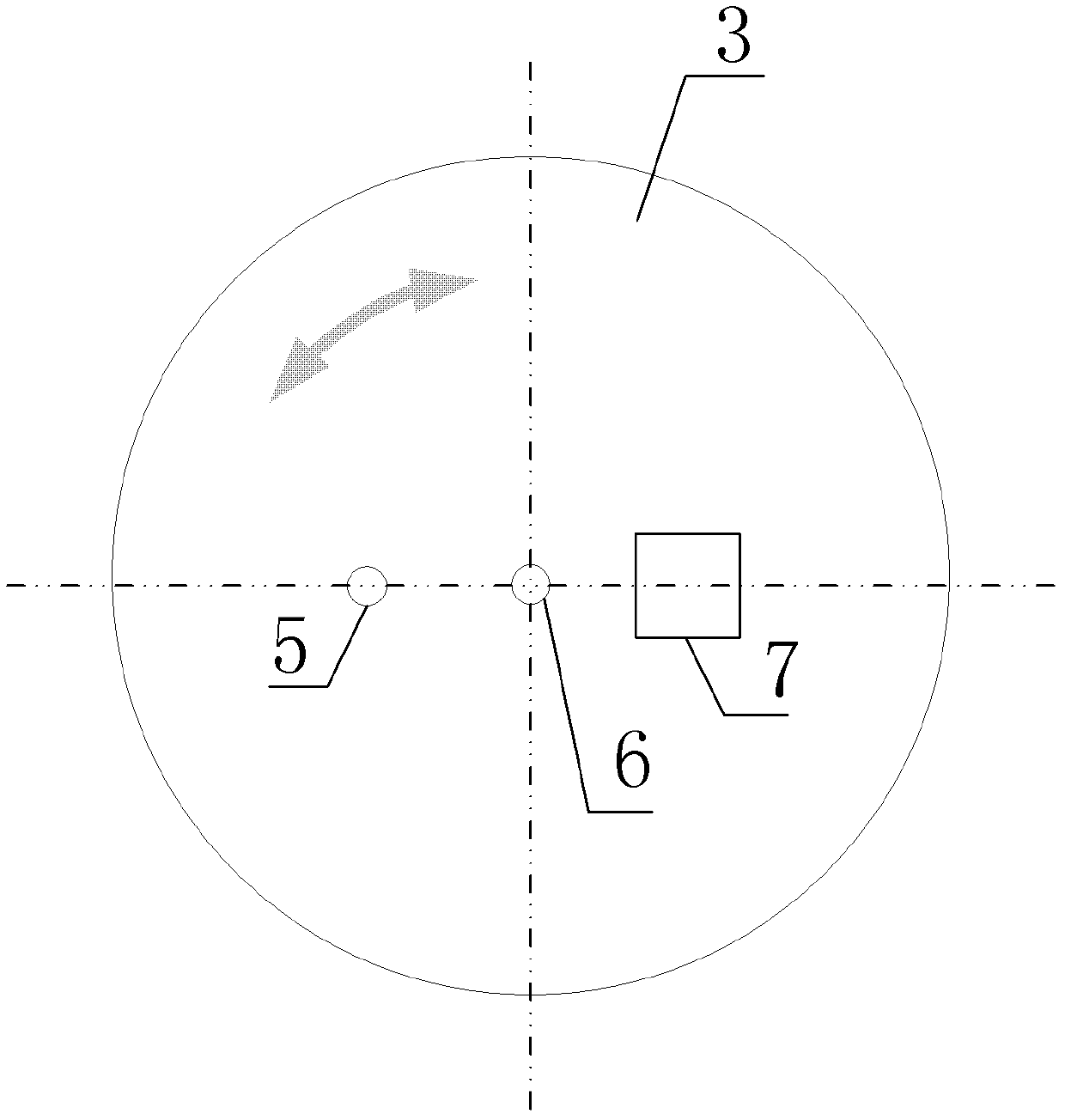

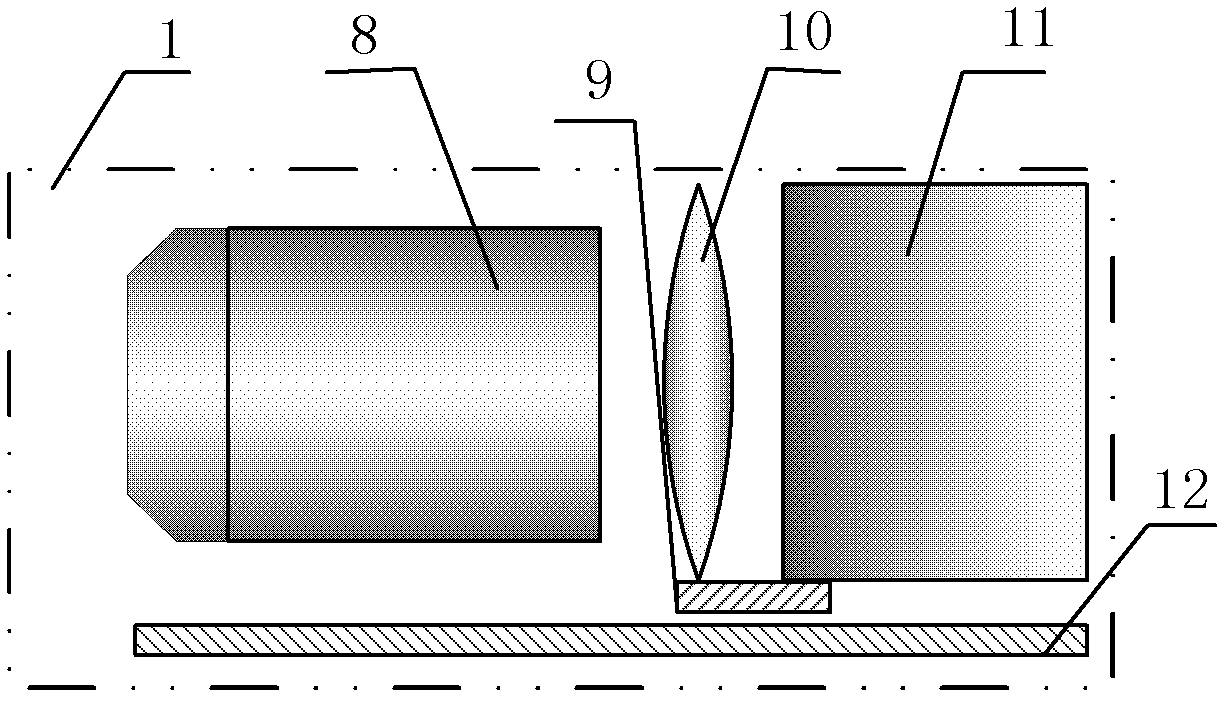

[0016] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment mode, a kind of high-precision testing device of optical element surface shape error described in this embodiment mode, detection device 1, illumination system 2, rotatable small hole plate 3 and optical element 4 to be tested; Small orifice plate 3 is provided with small hole 5, central hole 6 and square hole 7; Rotatable small orifice plate 3 rotates with central hole 6 as the center of circle; The distances of the holes 6 are equal, and the diameters of the central holes 6 are respectively λ / 2NA, wherein NA is the numerical aperture of the optical element to be measured; λ is the wavelength of the light beam emitted by the illumination system 2; the light beam emitted by the illumination system 2 passes through the rotatable The central hole 6 of the small hole plate 3 produces an ideal test beam, which is collected by the detection device 1 after being reflected and converged ...

specific Embodiment approach 2

[0020] Specific embodiment 2. A high-precision testing method for the surface shape of an optical element, the method is realized by the following steps:

[0021] Step A, building a detection platform for the optical imaging system;

[0022] Step B, align the detection device 1 in the detection platform described in step one with the small hole 5 on the rotatable small hole plate 3, and move the precision axial fine-tuning guide rail 9 in the detection device 1 back and forth to obtain 5 different out-of-focus star point images of diffraction;

[0023] Step C, calculating the optical wavefront error of the detection device 1;

[0024] Step D, align the detection device 1 in the detection platform described in step one with the larger square hole 7 on the rotatable small orifice plate 3, and move the precision axial fine-tuning guide rail 9 in the detection device 1 back and forth, so that Obtain different out-of-focus star point images passing through the square hole 7;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com