Collapsible loess tunnel construction method

A technology for collapsible loess and tunnel construction, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of upper road surface subsidence, soil damage, subsidence, etc., and achieve the effect of ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Collapsible loess tunnel construction method of the present invention, carry out according to the following steps:

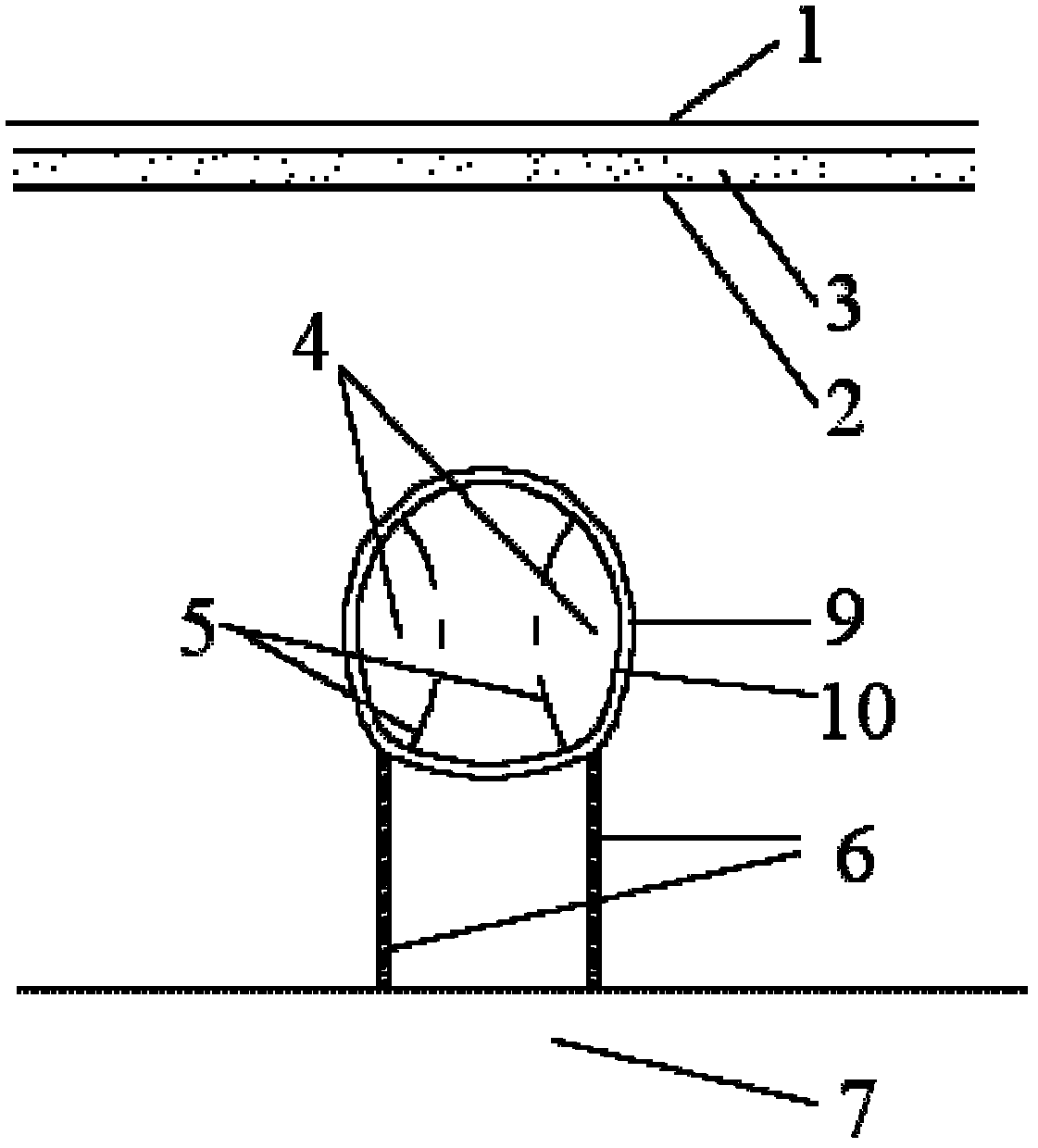

[0022] Step 1. Before excavating the tunnel, first set up a water-resisting layer 2 at a certain distance below the road surface 1 directly above the tunnel, and lay a sandstone layer 3 between the road surface 1 and the water-resisting layer 2 .

[0023] Such as figure 1 As shown, the water-resistant layer 2 is formed by ramming plain soil, the distance between the bottom of the water-resistant layer 2 and the road surface 1 is 1m-1.2m, and the thickness of the water-resistant layer 2 is 27cm-33cm. The gravel layer 3 is made of sand, gravel or coarse sand, and the thickness of the gravel layer 3 is 27cm-33cm.

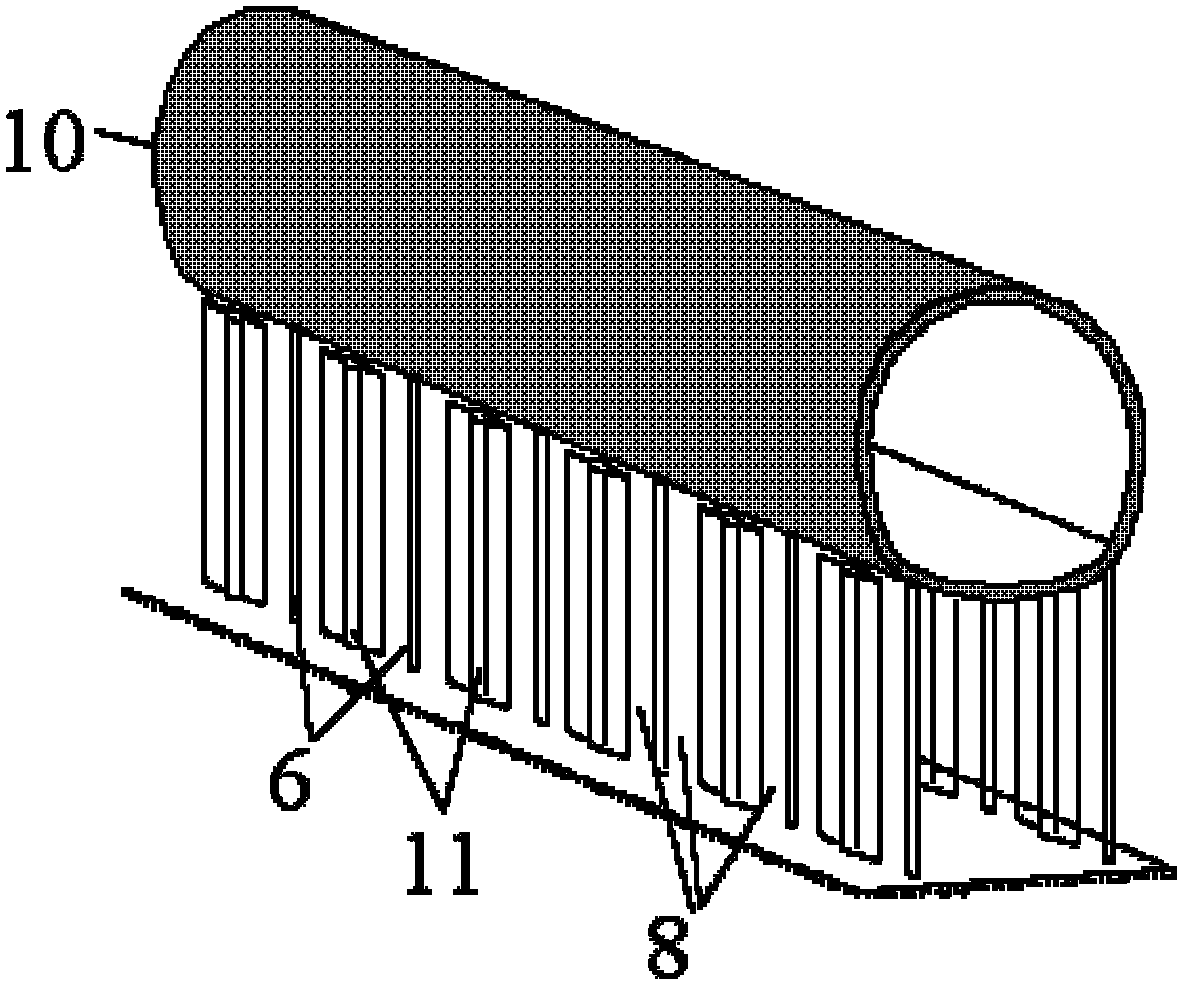

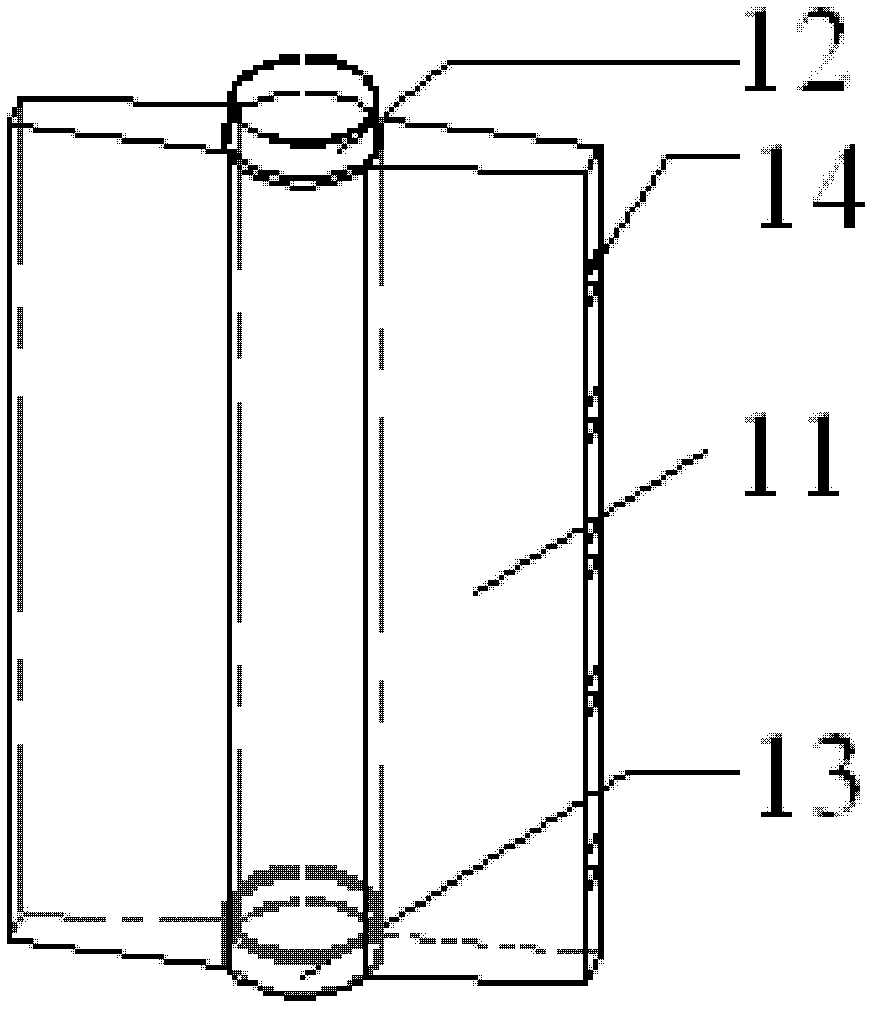

[0024] Step 2. Excavate the tunnel using the double pilot tunnel method. First, excavate the side pilot tunnels 4 on the left and right sides of the tunnel. Temporary steel arch supports 5 are respectively installed in the two side pilot tunnels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com