Compaction positioning mechanism for bridge U rib assembly machine

A positioning mechanism and assembly machine technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of a large amount of work time, difficulty, and high consumption costs, and achieve fast and convenient operation, high work efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

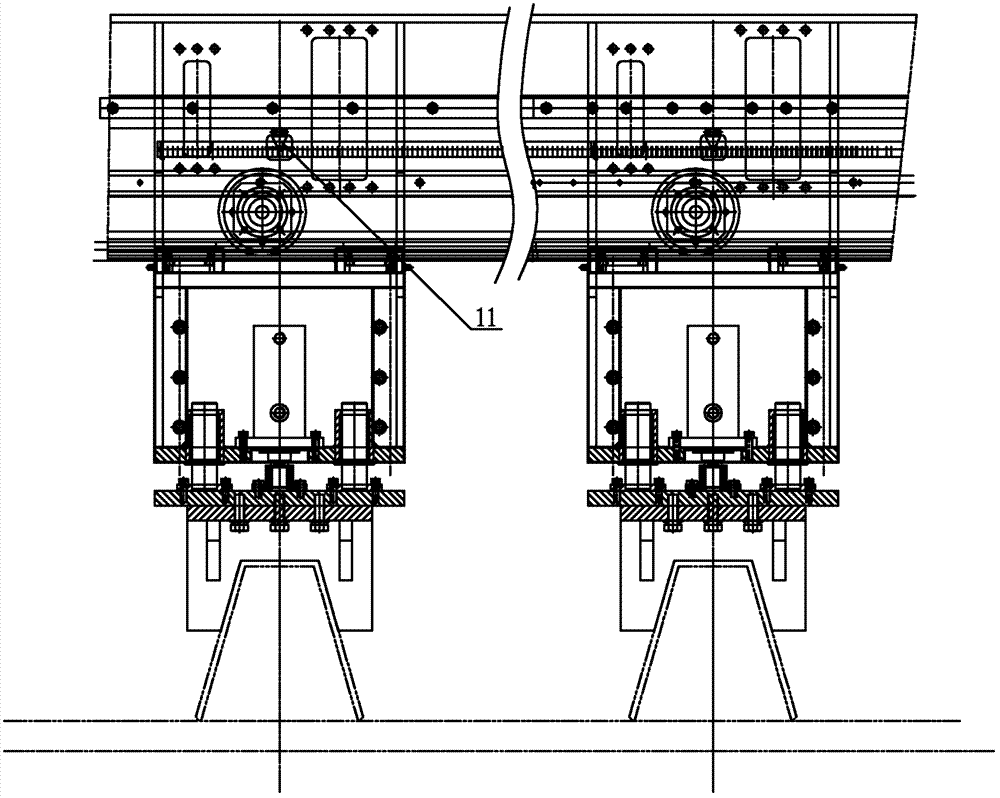

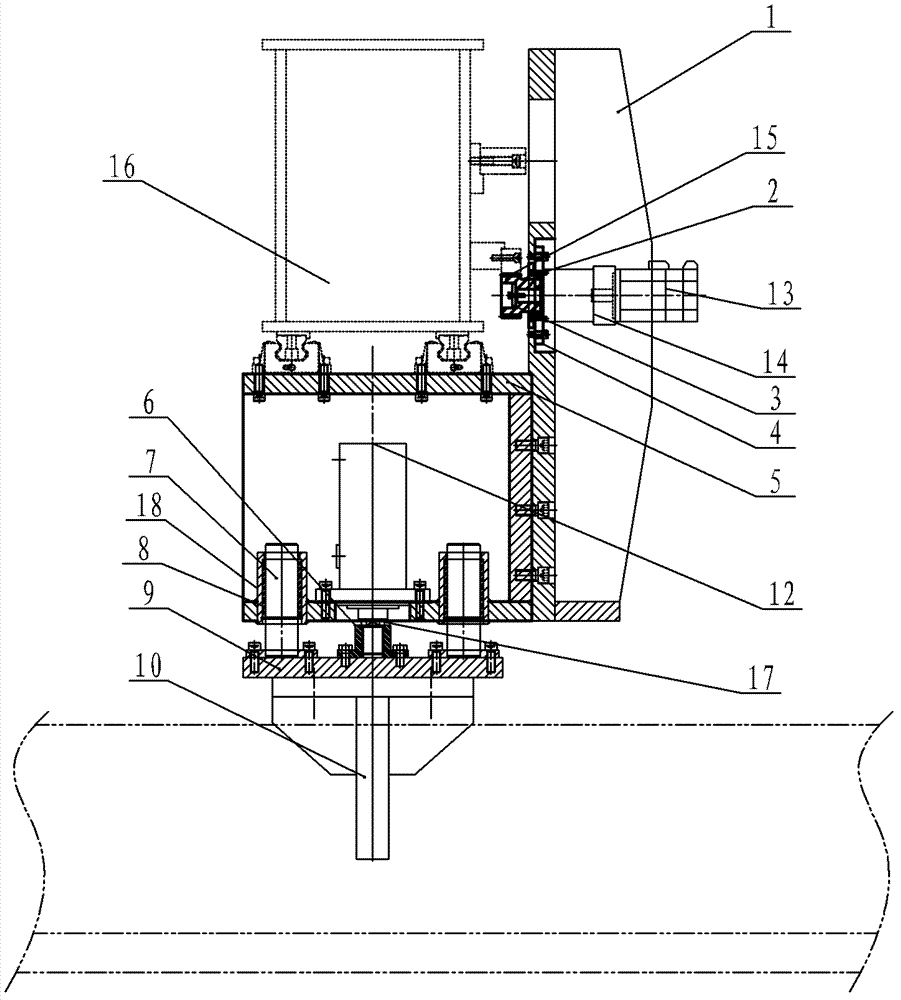

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0017] Such as Figure 1~Figure 2 As shown, the present invention mainly includes a mounting seat 1, a traverse gear 2, a mounting plate 4, a moving seat 5, a connecting seat 6, a guide rod 7, a fixed seat 9, a pressure plate 10, a hydraulic cylinder 12, a servo motor 13 and a reducer 14 .

[0018] The servo motor 13 is connected with a speed reducer 14, and the rotating shaft of the speed reducer 14 is covered with a traverse gear 2. The traverse gear 2 is engaged with the fixed rack 15 on the assembly machine 16 . The reducer 14 is installed on the mounting plate 4 , and the mounting plate 4 is mounted on the mounting seat 1 .

[0019] The lower end of the mounting base 1 is connected to the moving base 5, the upper end of the moving base 5 is installed on the assembly machine 16, and the hydraulic cylinder 12 is installed in the moving base 5. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com