Emergency state control system of continuous annealing furnace on continuous assembly line

A continuous annealing furnace, emergency state technology, applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of excessive tension change in the furnace, broken belt stop in the furnace, thermal buckling, etc., to save the system emergency time. , The effect of reducing labor intensity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

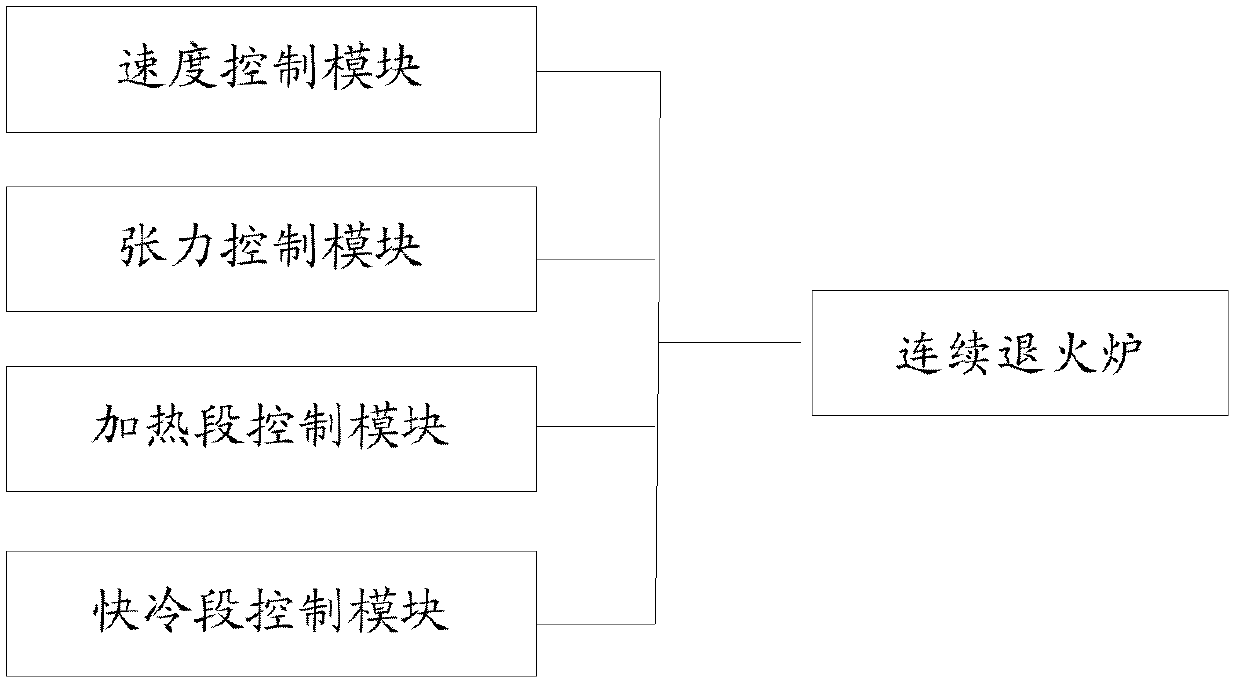

[0034] Such as figure 1 As shown, the emergency state control system of a continuous annealing furnace on a continuous production line provided by the present invention includes a speed control module, a tension control module, a heating section control module and a fast cooling section control module. The speed control module is used to set and quickly adjust the operating speed of the continuous annealing furnace zone; the tension control module is used to quickly adjust the tension value of the continuous annealing furnace zone; the heating section control module is used to quickly switch the heating mode of the continuous annealing furnace zone To the standby mode; the fast cooling section control module is used to set the speed of the fan in the fast cooling section and quickly convert the fan speed to the set value speed.

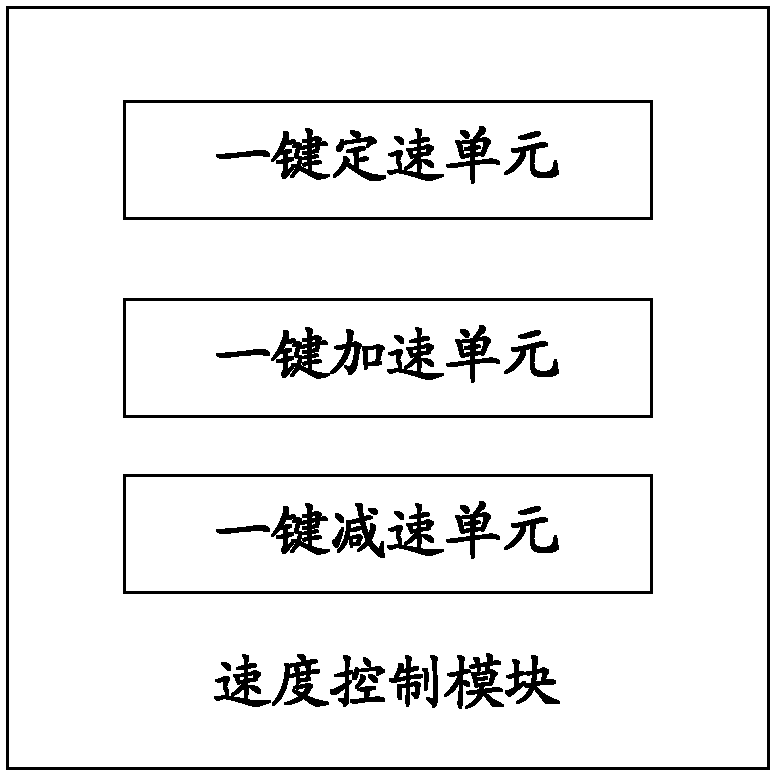

[0035] Wherein, the speed control module is arranged on an operation table. Such as figure 2 As shown, the speed control module includes a one-key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com