Method for improving iron content and reducing sulfur content by direct reduction of carbon-containing pellets in rotary hearth furnace

A rotary hearth furnace, direct technology, used in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of sulfur reduction, high sulfur content in products, addition of sulfur reducing agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] The method for the direct reduction of carbon-containing pellet rotary hearth furnace of the present invention to raise iron and reduce sulfur, its preferred embodiment is:

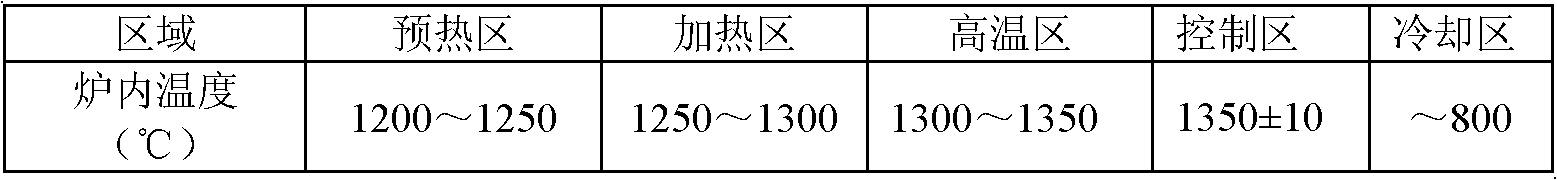

[0012] Mix 64-84 parts by weight of iron oxide scale, 19-25 parts of semi-coke, 4-10 parts of limestone, and 9-11 parts of composite binder, press balls, dry, and spread in the rotary hearth furnace Internal reduction at 1200-1400 °C, the atmosphere in the rotary hearth furnace is a neutral atmosphere or a weakly reducing atmosphere, and the reduction time is 25-45 minutes;

[0013] After the reduction product is cooled, the metal particles are separated from the sulfur-rich gangue or slag by fine grinding and magnetic separation.

[0014] Said iron oxide scale: it is produced during forging and hot rolling of steel, with a particle size of ≤3mm.

[0015] In the semi-coke or semi-coking coal: fixed carbon ≥ 78% by weight, ash content ≤ 10% by weight, volatile matter ≤ 8% by weight, S ≤ 0.50% by we...

specific Embodiment

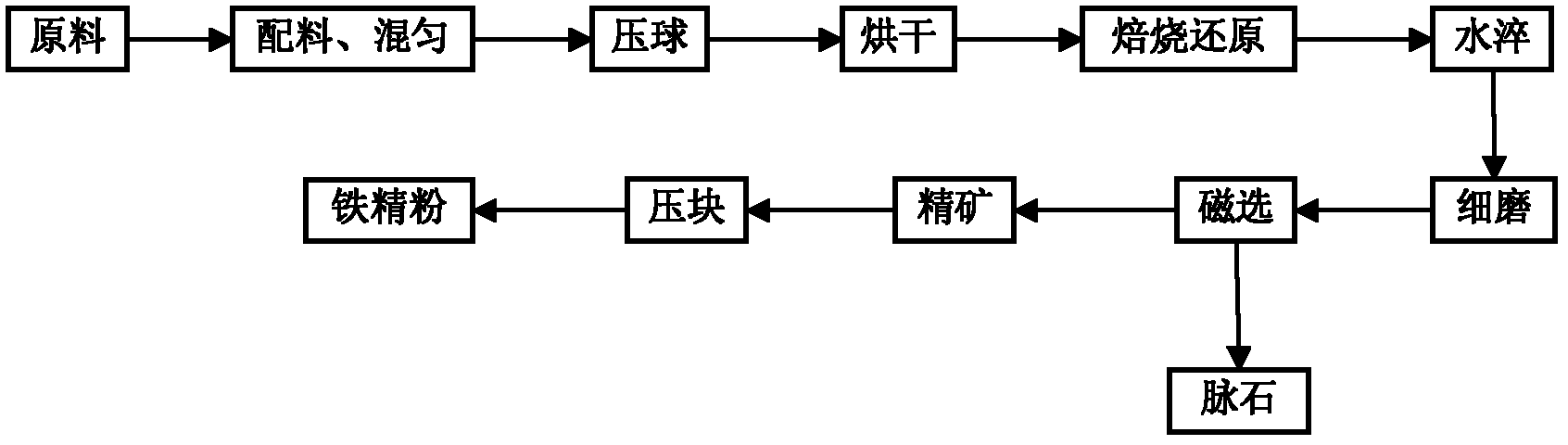

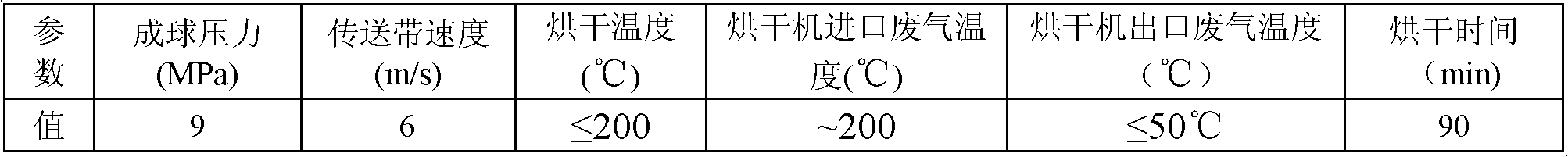

[0022] Schematic diagram of the method for direct reduction of iron, iron, and sulfur reduction in a carbon-containing pellet rotary hearth furnace—— figure 1 Among them, the raw materials include powdered iron oxide scale, semi-coke powder, powdered limestone particles, and the composite binder is composed of solid bentonite and PVA solution. The quality requirements of each raw material are: powdered iron oxide scale particle size ≤ 3mm; fixed carbon of blue charcoal powder ≥ 78wt%, ash content ≤ 10wt% volatile matter ≤ 8wt%, S ≤ 0.50wt%, particle size ≤ 2mm and particle content greater than 70wt% ; CaO ≥ 55wt% of limestone, SiO ≤ 3wt%, particle size ≤ 0.074mm and particle content greater than 70wt%; the solid bentonite content of the composite binder is 30wt%, and the PVA solution content is 70wt%, wherein the concentration of PVA is 5-7wt%. The operating points of the batching and mixing process: dry mix all solid powders on the mixer for 5 minutes according to the determi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com