Coagulating sedimentation device

A technology of coagulation, sedimentation and coagulation, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of easy damage of the agitator, troublesome equipment maintenance, and difficult maintenance, so as to reduce costs, reduce maintenance costs, and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

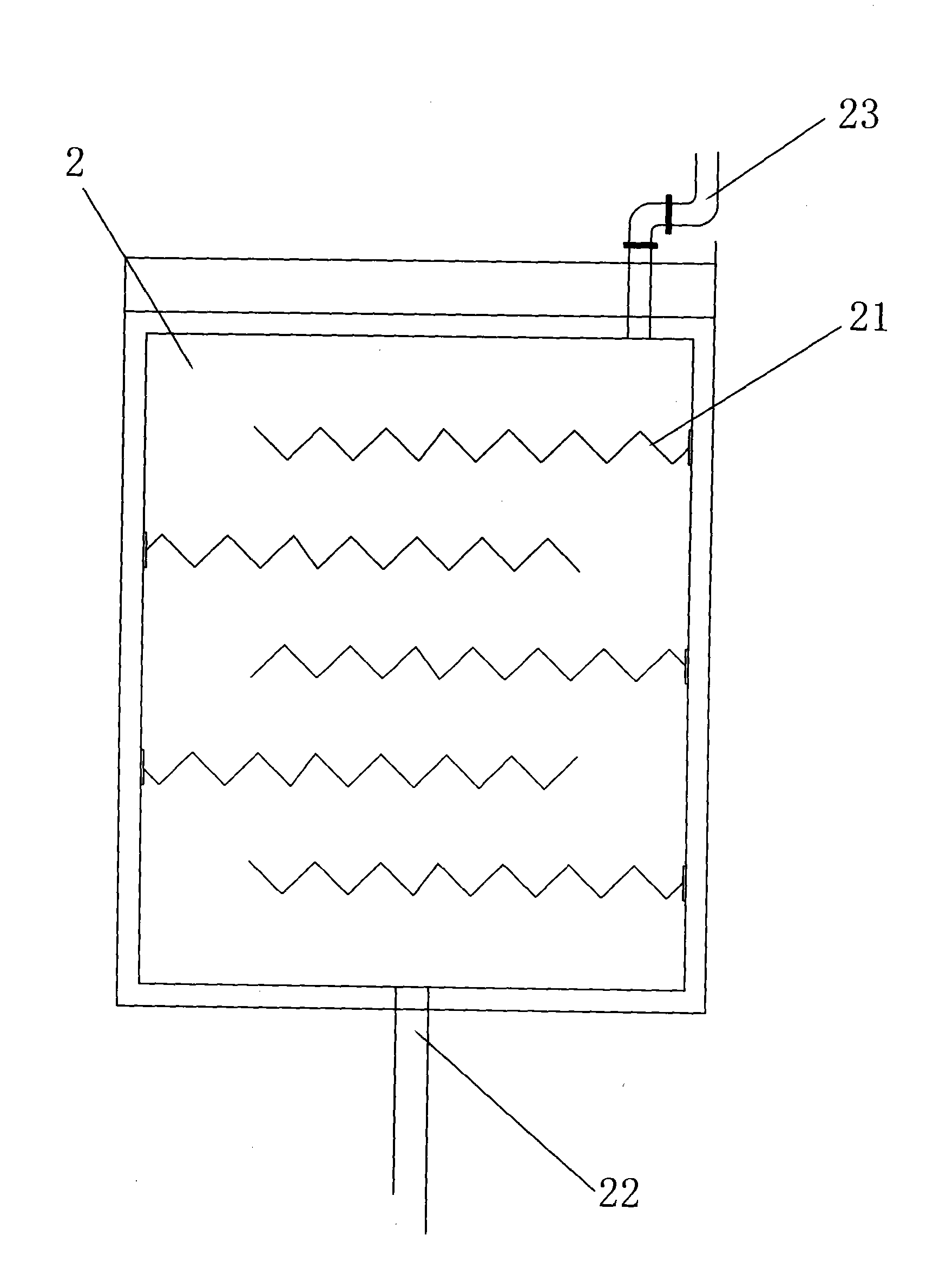

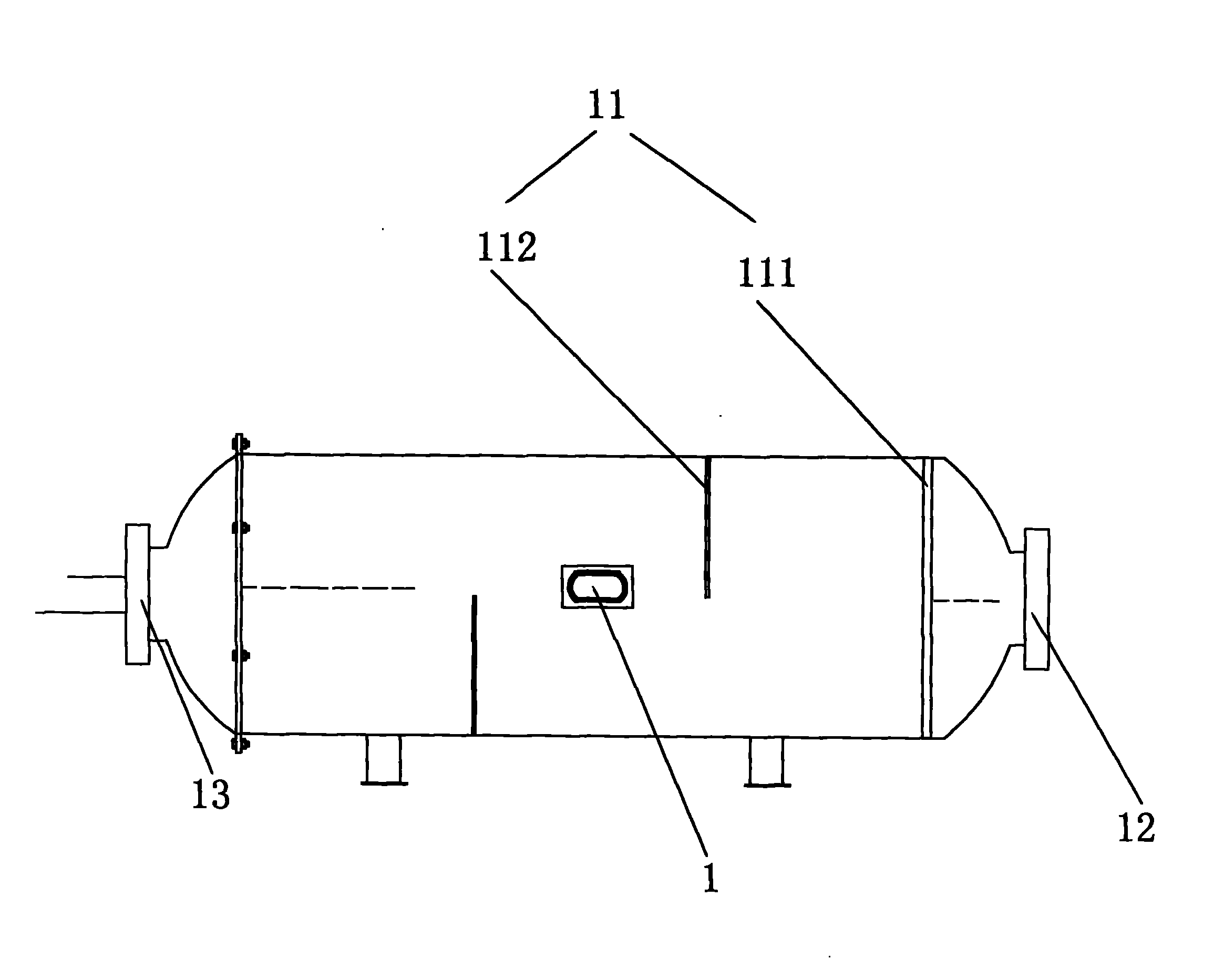

[0026] Such as figure 1 ,Such as figure 2 ,Such as image 3 and as Figure 4 As shown, a coagulation sedimentation equipment includes a mixing reactor 1 and a coagulation reaction tank 2, the mixing reactor 1 is connected to the coagulation reaction tank 2 through pipelines, and the mixing reactor 1 includes First inlet 12 and first outlet 13, described coagulation reaction tank 2 comprises second inlet 22 and second outlet 23, described first outlet 13 links to each other with described second inlet 22, described coagulation reaction tank 1 There are baffles 21 for blocking water flow, the baffles 21 are corrugated baffles, the width of the baffles 21 is smaller than the width of the coagulation reaction tank 2, and the baffles 21 are alternately arranged on the coagulation The left and right sides of the reaction pool 2.

[0027] The mixing reactor 1 is horizontal, and a peep mirror 14 and a manhole (not shown) are arranged in the middle of the mixing reactor 1, and a m...

Embodiment 2

[0034] Such as Figure 5 As shown, the rest are the same as in Example 1, except that the one mixing reactor 1 is connected with two coagulation reaction tanks through pipelines. The coagulation and sedimentation equipment can also achieve the goals of environmental protection, energy saving, and convenient equipment maintenance. In addition, the efficiency of flocculation and sedimentation is also improved to meet the requirements of sewage treatment with a large flow rate.

[0035] In the present invention, two mixing reactors 1 can also be connected to two coagulation reaction tanks, the quantity of mixing reactor 1 and the quantity of coagulation reaction tank 2 are set according to actual requirements, and the present invention does not make any limitation. Mainly to be able to realize the present invention.

[0036] The beneficial effect of adopting the technical solution of the present invention is: a coagulation sedimentation equipment, comprising a mixing reactor 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com