Railway truck head wall spreader

A technology for railway wagons and end walls, applied in the field of spreaders, can solve problems such as difficult installation and fixation, low production efficiency, cumbersome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

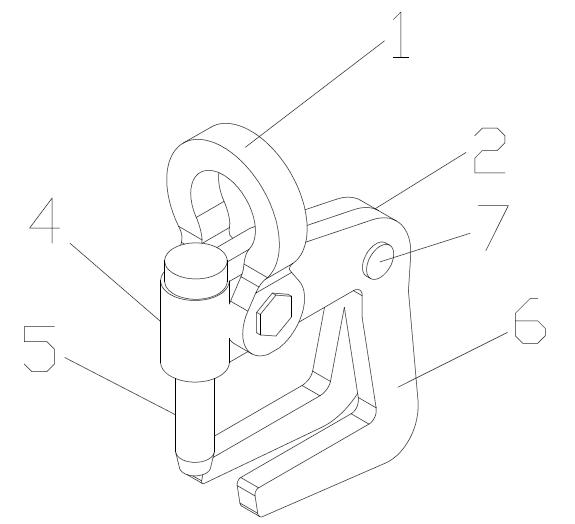

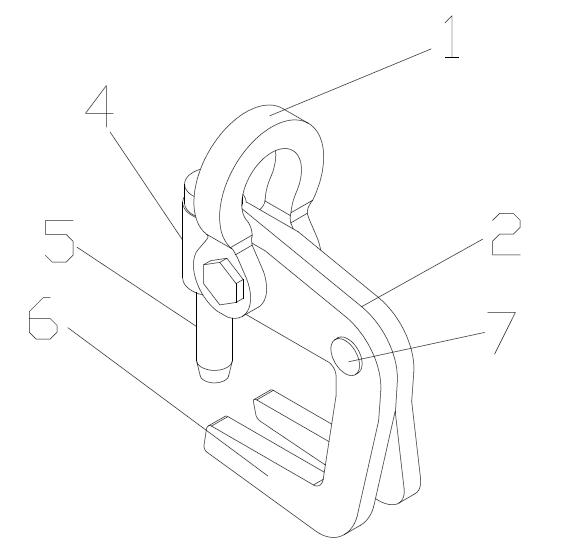

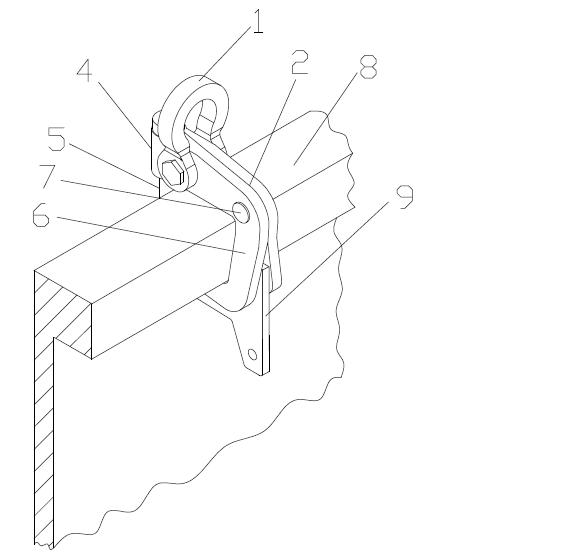

[0011] Depend on Figure 1-3 From the shown embodiment, it can be known that it includes a shackle 1 and a hook 2 connected to the shackle 1. In addition, a vertical movable stop is provided on the opening side of the hook 2, and a The opening slot, the space formed by the combination of the vertical movable retainer and the hook 2 is suitable for the cross-section of the rib plate 9 in the middle of the end beam 8 on the end wall; the vertical movable retainer is a vertical movable positioning pin, which It includes a pin hole seat 4 fixedly connected to the upper part of the opening side of the hook 2 and a pin 5 slidingly fitted in the pin hole seat 4; the pin hole seat 4 of the vertical movable positioning pin is a steel pipe welded with the hook 2; The hook 2 is formed by riveting the half hooks 6 with the lower parts of the two hook bodies inclined outwards by rivets 7 .

[0012] In addition, the vertical movable blocking card can also be a metal rod connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com