Shaft processing fixture

A technology of fixtures and shafts, which is applied in the field of mechanical processing auxiliary fixing fixtures, can solve the problems of large machining errors and difficulty in fixing workpieces, and achieve the effects of increasing the pressing area, increasing stability, and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

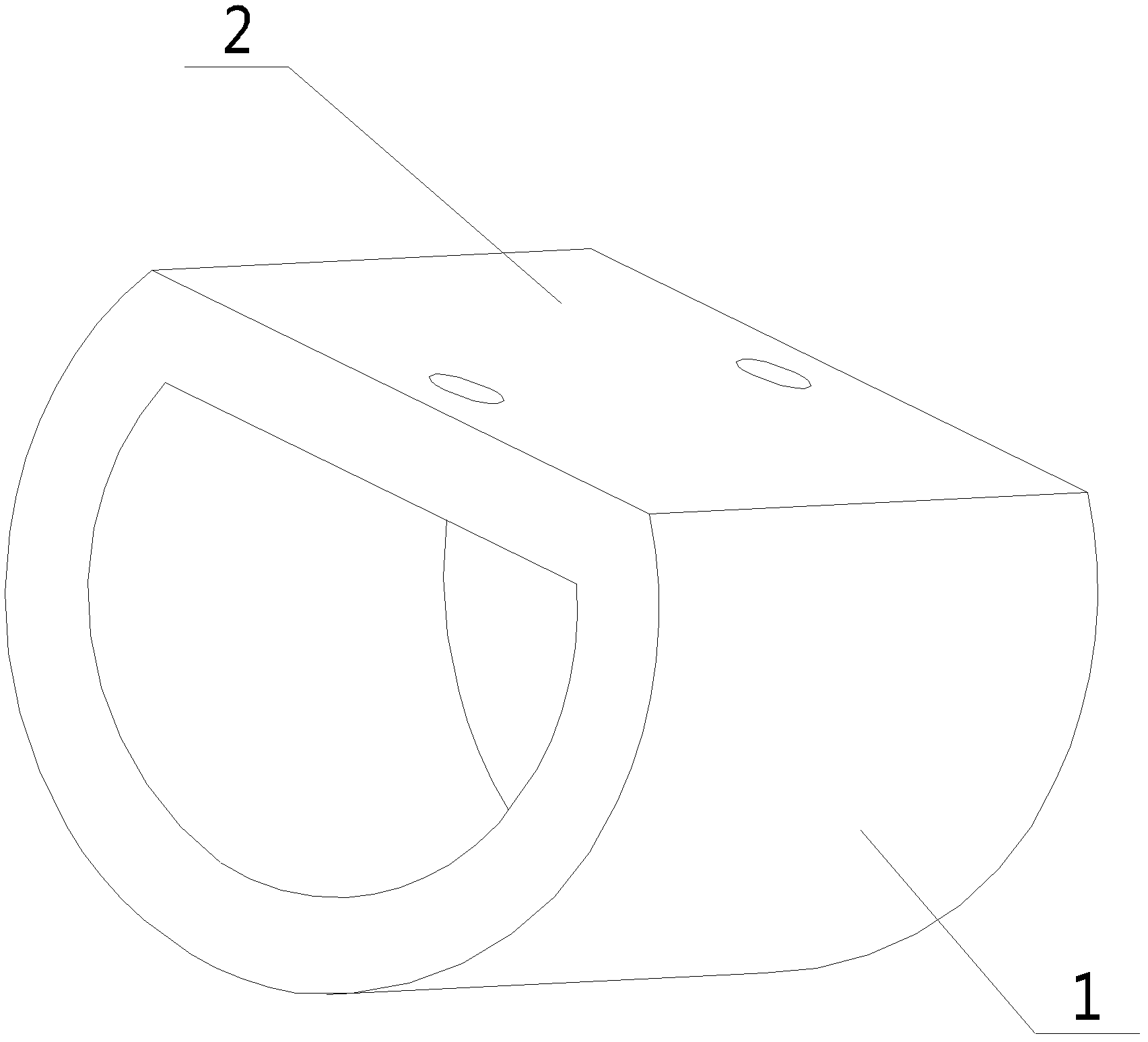

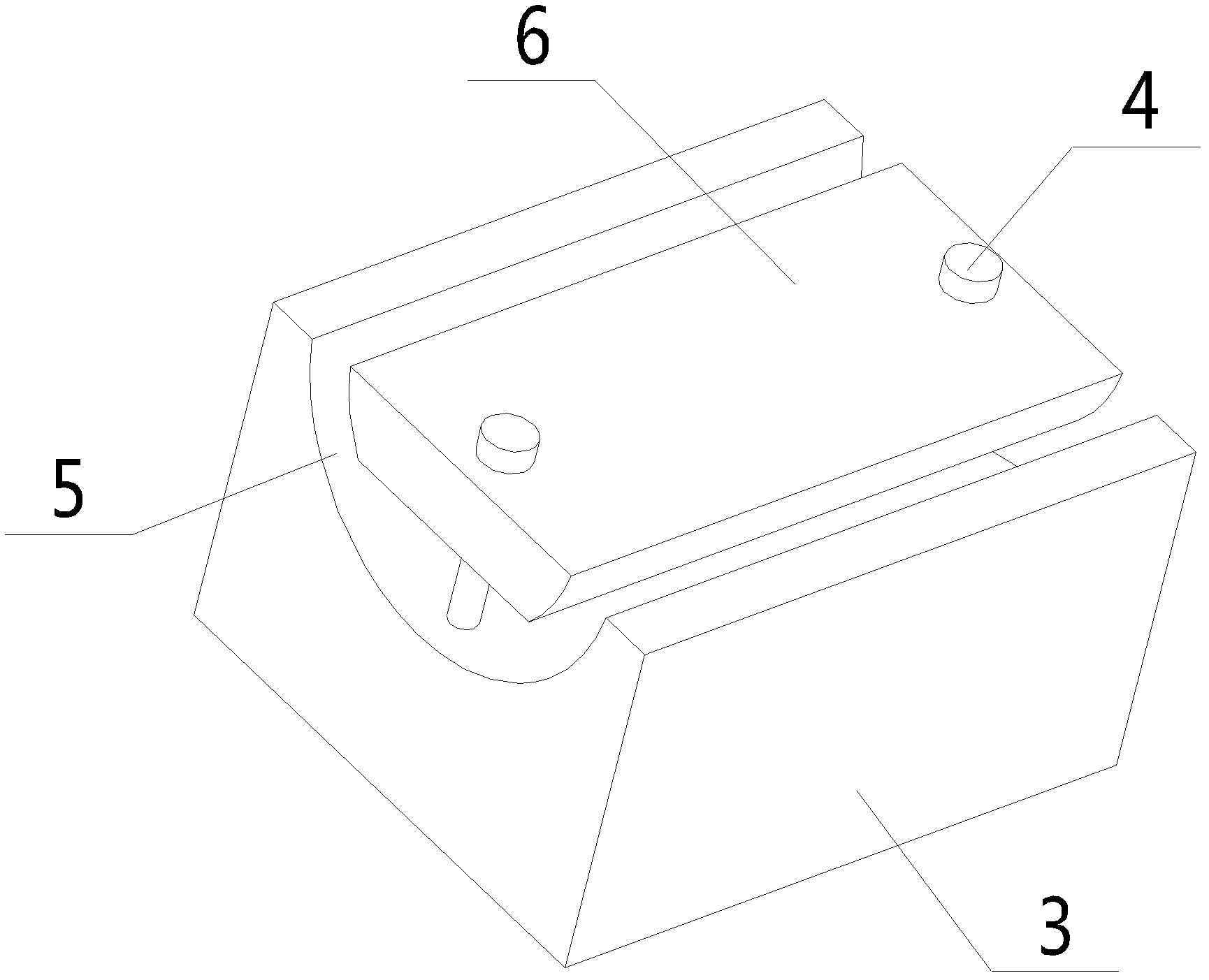

[0017] with processing attached figure 1 Take the top surface 2 of workpiece 1 shown in as an example, with Figure 2-4 It is a kind of shaft processing fixture according to the present invention, which includes a clamp body 3, a pressure block 6 and a compression bolt 4; the clamp body 3 is a cuboid, and the center of the top surface of the clamp body 3 is provided with an accommodation groove 5 The cross-section of the accommodating groove 5 is arc-shaped; the left and right sides of the briquetting block 6 in contact with the accommodating groove 5 are arc-shaped surfaces; The radians of 5 are the same; the upper and lower surfaces of the briquetting block 6 are planes, and the length of the briquetting block 6 is the same as that of the accommodating groove 5; the briquetting block 6 is located above the accommodating groove 5, and passes through the The compression bolt 4 compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com