Cold heading moulding die for tyre bolt

A technology for forming molds and bolts, which is applied in the direction of bolts, manufacturing tools, threaded fasteners, etc., can solve the problems of reducing the tensile strength of bolts, failing to guarantee the performance level, and unable to guarantee the coaxiality of the screw, etc., so as to improve the tensile strength, The effect of increasing strength and ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

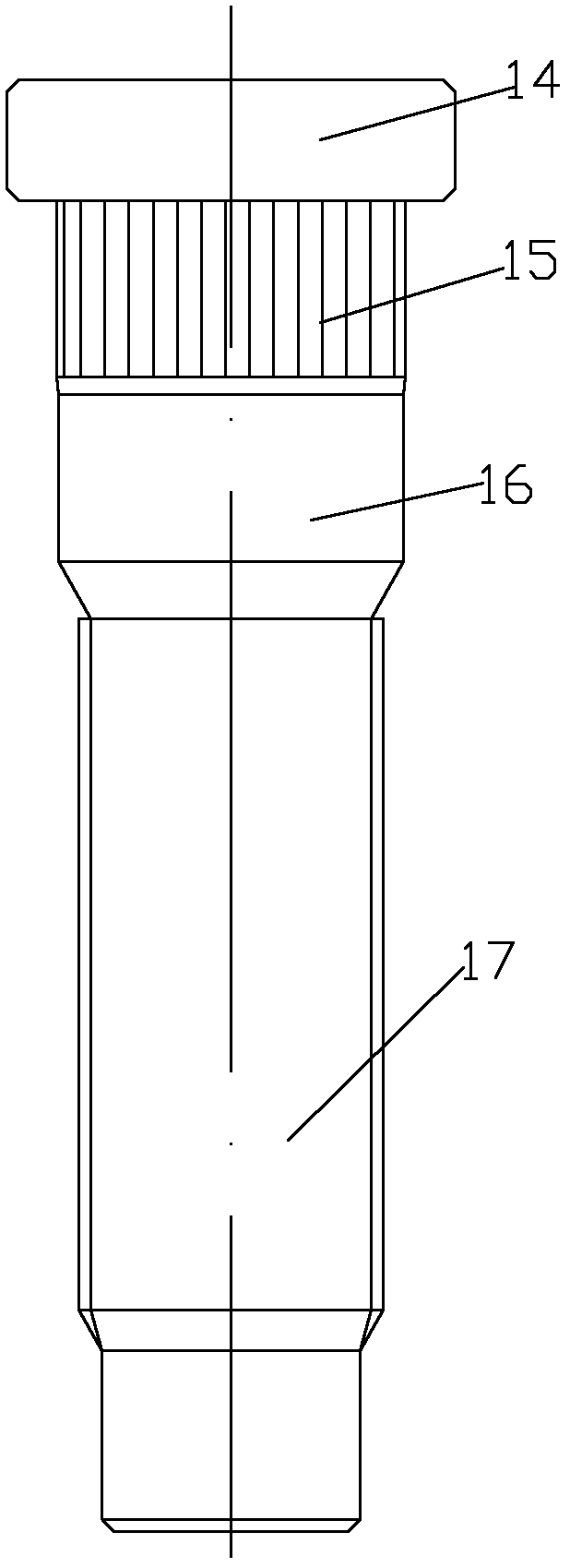

[0016] attached figure 1 It is a structural diagram of a tire bolt of the present invention, including a bolt head 14 , a straight-grained shank 15 , a polished shank 16 and a threaded shank 17 .

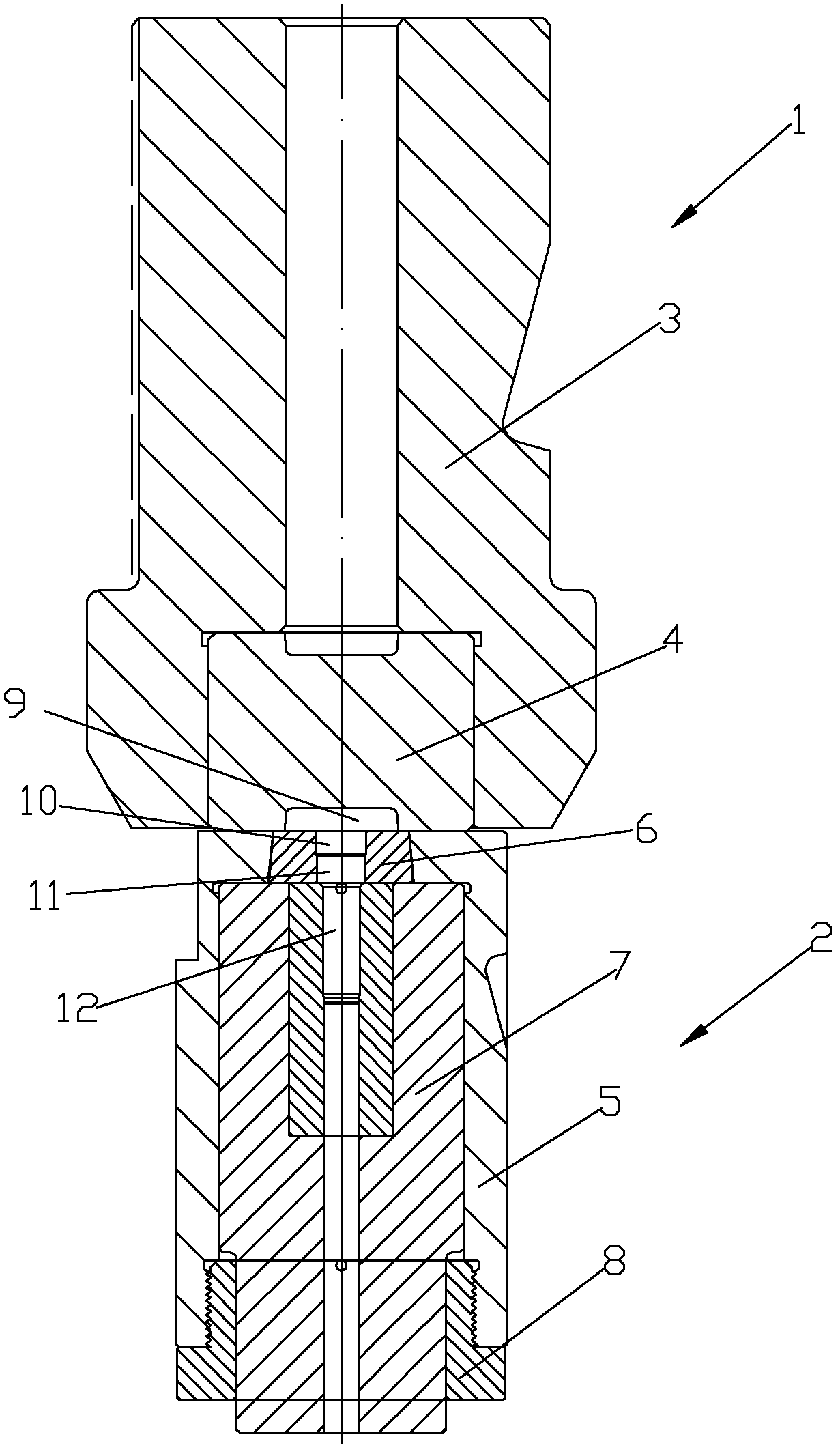

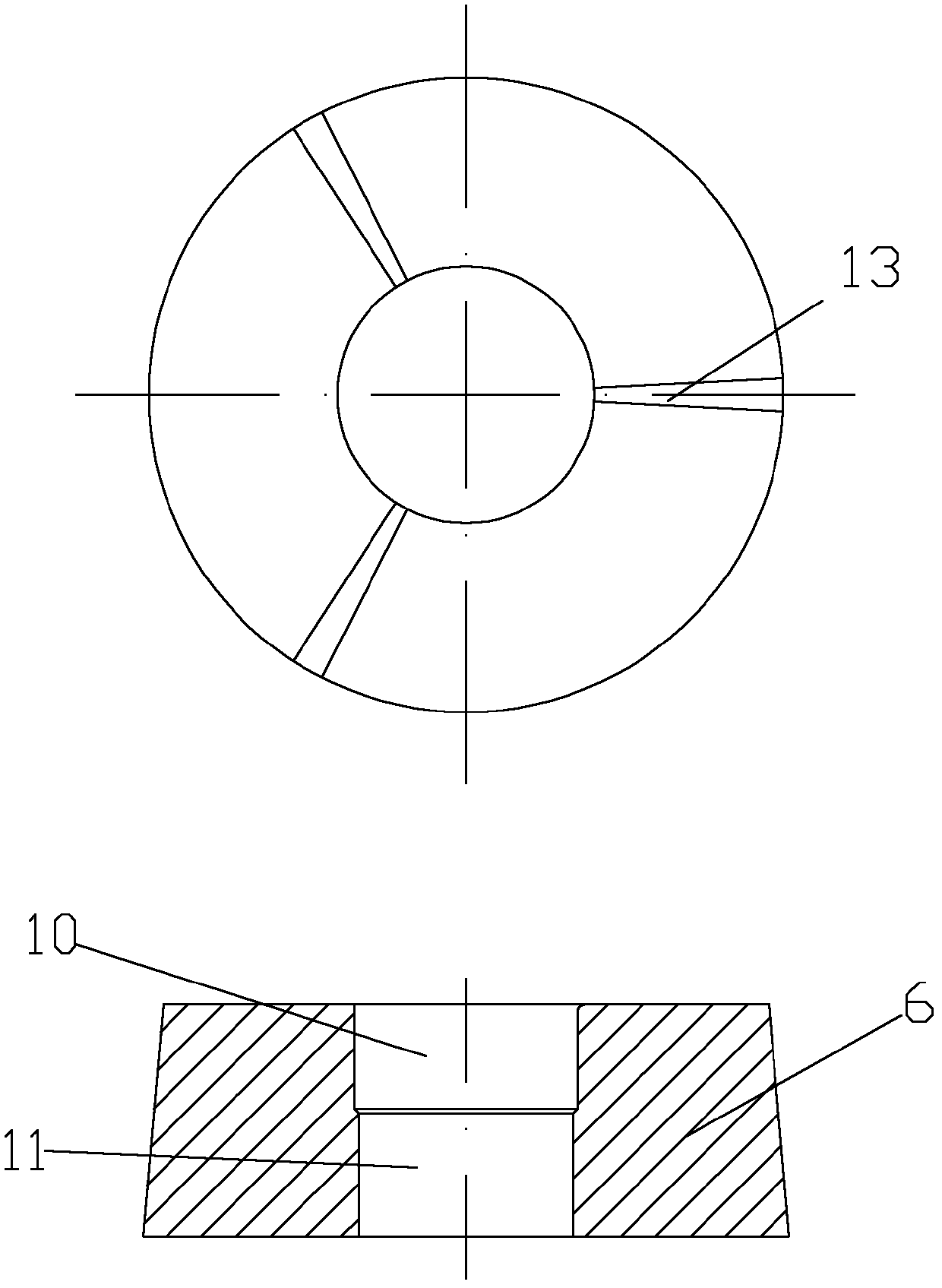

[0017] attached figure 2 , 3 It is a tire bolt cold heading forming die according to the present invention, which includes a punching die 1 and a lower die 2 used in conjunction with the punching die 1. The punching die 1 includes a punching shell 3 and a punching core 4 arranged at the bottom of the punching shell 3. The lower mold 2 includes a mold shell 5, and the mold shell 5 is provided with a mold piece 6 and a mold core 7. The mold piece 6 is tightly connected to the mold core 7, and the other end of the mold core 7 is locked by a locking sleeve 8. Tightly in the mold shell 5; the two ends of the punching core 4 are symmetrically provided with a bolt head cavity 9; the die sheet 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com