Shaping mold for bulb bayonets

A mold and bayonet technology, which is applied in the field of molds for shaping the light bulb bayonet, can solve the problems of easy falling off or deformation, large errors, and the light bulb bayonet cannot be well socketed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

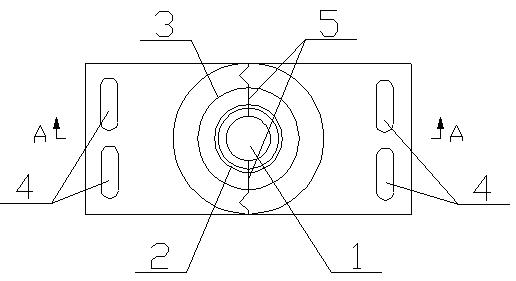

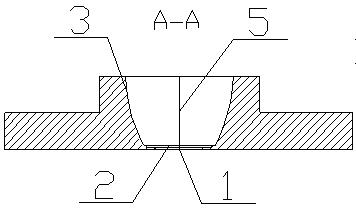

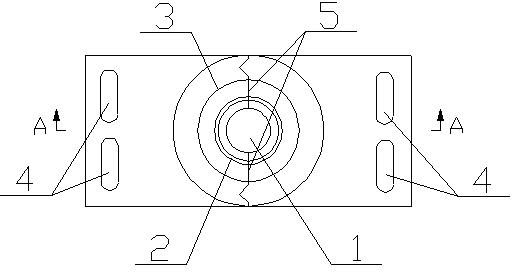

[0010] like figure 1 , 2 As shown, the present invention discloses a shaping mold for a light bulb bayonet. The mold is set on the end of the shaping claw in the light bulb bayonet shaping device. The mold is composed of two symmetrical parts, and the bottom surface in the middle of the mold is set There is a round hole 1, the inner diameter of the upper side of the round hole 1 is provided with a stepped flange 2, and the upper side of the flange 2 is provided with an open arc-shaped inner circle 3, and the outer ends of the two parts of the mold are respectively provided with two A long oval through hole 4.

[0011] The butt joint surfaces 5 of the two parts of the mould, the said butt joint surfaces 5 are respectively set in a tooth shape near the upper and lower sides of the mould.

[0012] When the present invention is working, the through hole 4 is bolted to the end of the shaping claw in the plastic device, and the closing of the shaping claw makes the shaping mold do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com