Junked tire recovery device

A waste tire and recycling device technology, which is applied in plastic recycling, recycling technology, solid waste removal, etc., can solve the problems of limiting the effective recycling of waste tires and the separation of rubber and steel wire in waste tires. Achieve the effects of improving the working environment, reducing secondary pollution, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

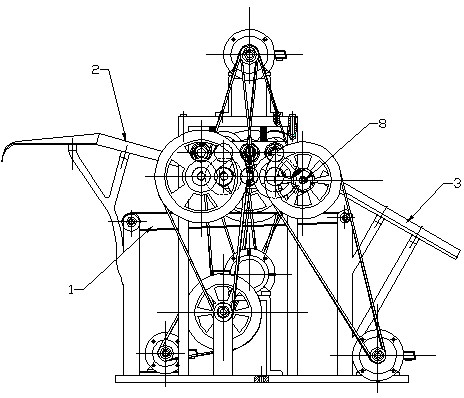

[0013] The technical scheme of the device of the present invention will be further specifically described below in conjunction with the accompanying drawings.

[0014] As shown in the figure, the waste tire recovery device includes a frame 1, a feed plate 2 is installed at the front of the frame, a discharge plate 3 is installed at the rear of the frame, and at least two groups of cutting devices are installed at the middle of the frame; A group of cutting devices includes a pair of pressure roller shafts 4 arranged up and down and a pair of milling cutter shafts 5 arranged up and down; a pair of pressure roller shafts are arranged at intervals and many pairs of pressure rollers 6 are arranged at intervals, and a pair of milling cutter shafts are arranged at intervals of Multiple pairs of cylindrical milling cutters 7, and the positions of adjacent milling cutters 7 and pressure rollers 6 are staggered from each other in the axial direction; the milling cutters 7 in each group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com