Wastepaper sorting method

A waste paper and paper-based technology, applied in the field of waste paper sorting, can solve the problems of mixed sorting paper quality, rough sorting, lack of sorting standard sorting personnel training, etc., achieve reasonable and reliable equipment configuration and layout, and reduce labor costs. The effect of improving labor intensity and waste paper sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

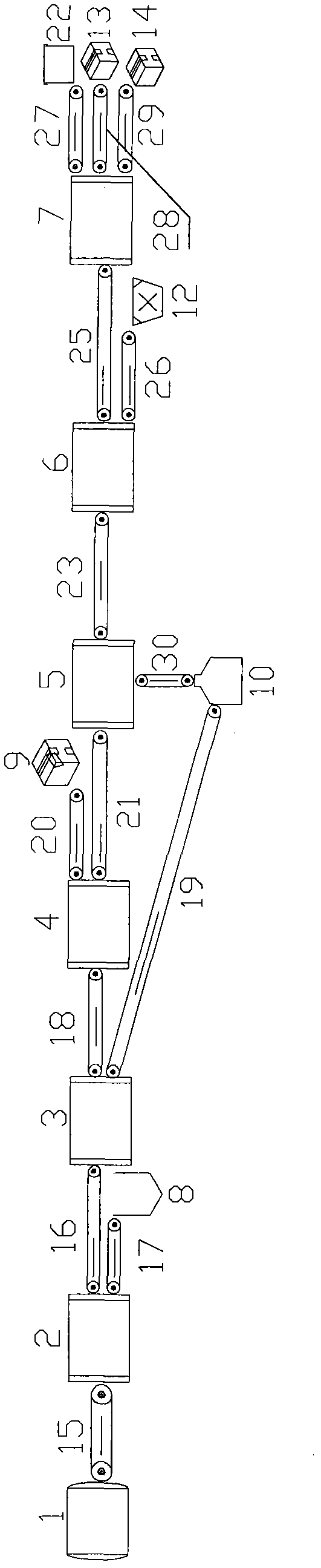

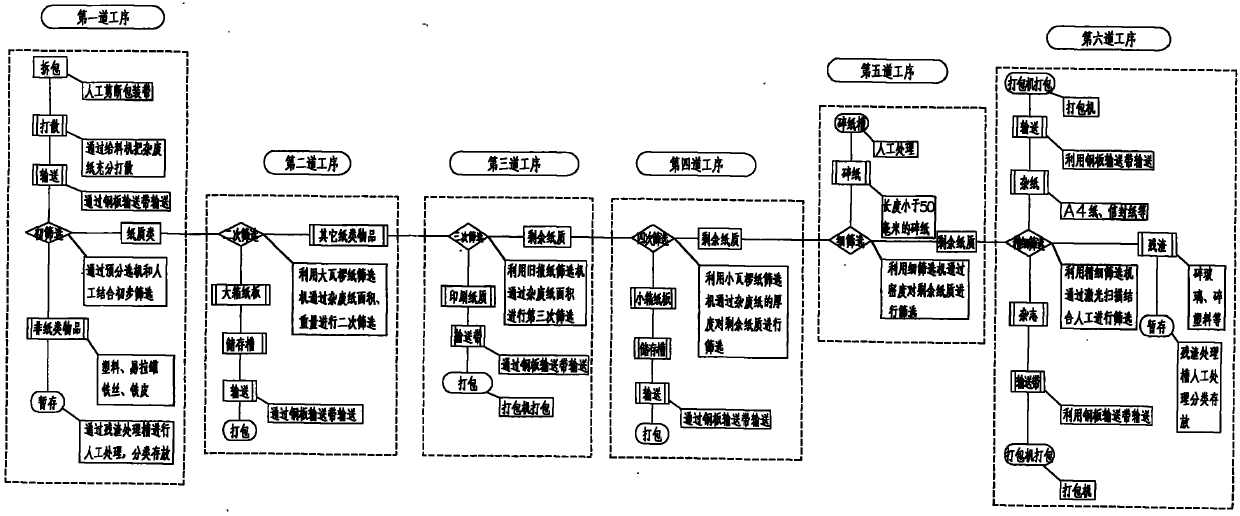

[0019] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0020] In this embodiment, the No. 2 mixed waste paper of the "American Waste Paper Classification Standard" is taken as an example for sorting. This kind of waste paper is mixed with waste paper of different quality after sorting, and is packaged for delivery. The grinding of this kind of waste paper The content of wood pulp shall not exceed 10%, the mixed impurities shall not exceed 0.5%, and the total amount of unqualified waste paper shall not exceed 3%. Including paper items, such as: cardboard, waste newspapers, magazines, office paper, etc.; non-paper items, such as: broken glass, waste plastics, cans, etc.

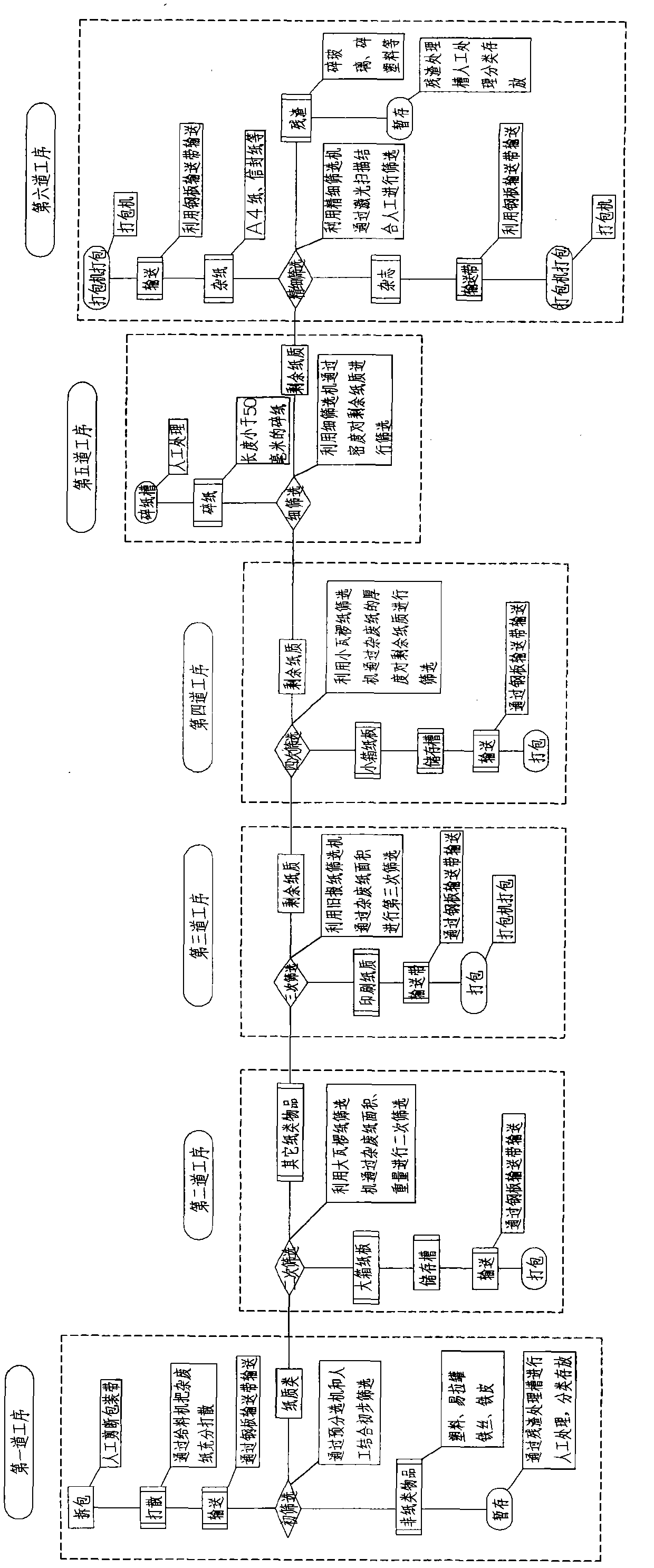

[0021] Such as figure 1 Shown, a kind of waste paper sorting method, its steps are:

[0022] (1) The first process: This process is a combination of mechanical and manual screening. After manually cutting the packaging belt of the mixed waste paper, the mixed waste paper i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com