Modularization sealing device for kettle

A sealing device, modular technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problems of wasting installation time and time-consuming installation actions, and achieve disassembly and replacement. Fast-moving, time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

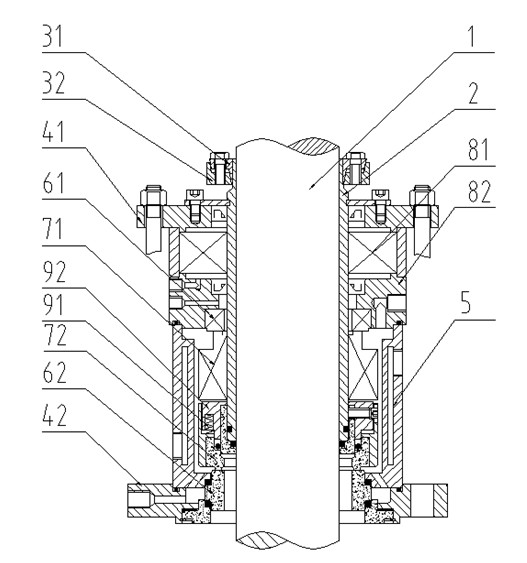

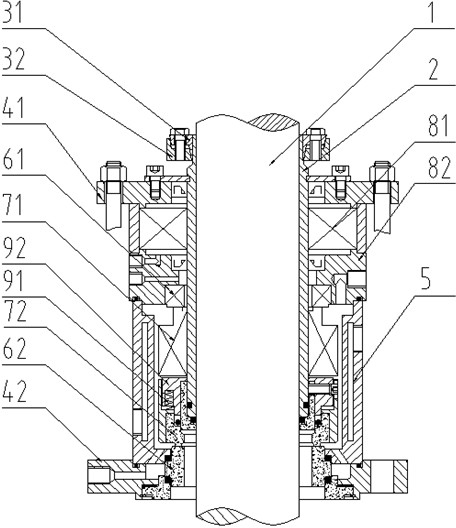

[0009] Embodiment: A modular sealing device for a kettle, including a stirring shaft 1, a shaft sleeve 2, the first and second driving parts 31, 32, the first and second flanges 41, 42, the sealing cylinder 5, the first and second The static rings 61, 62, the first and second moving rings 71, 72, the bearing 81, the bearing seat 82, the spring 91 and the spring seat 92 are based on the use direction, the second driving part 32 is fixedly connected with the first driving part 31, The bearing 81 is fixed on the inner upper end of the bearing seat 82, and the upper end of the bearing 81 is tightly pressed against the lower end of the first flange 41. The first and second stationary rings 61 and 62 are respectively sealed and fixed on the lower end of the bearing seat 82 and the upper end of the second flange 42. The first and second moving rings 71 and 72 are respectively sealed and fixedly sleeved on the outside of the shaft sleeve 2, one end of the spring 91 is fixed on the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com